In the heat exchanger manufacturing industry, "dense pipeline welding" has always been a troublesome issue — with pipes packed closely together, manual welding is not only difficult to operate but also prone to uneven welds and missed welds. What's more, it requires experienced technician-level welders, leading to high labor costs. Worse still, product quality fluctuates with the welders' performance. However, now Shanghai MeiHan Technology's MWH series heat exchanger U-tube welders have solved these problems.

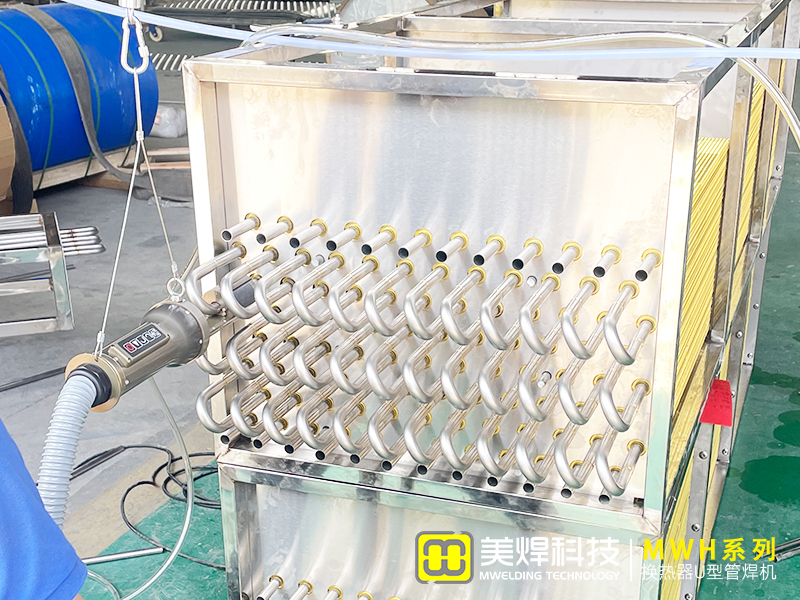

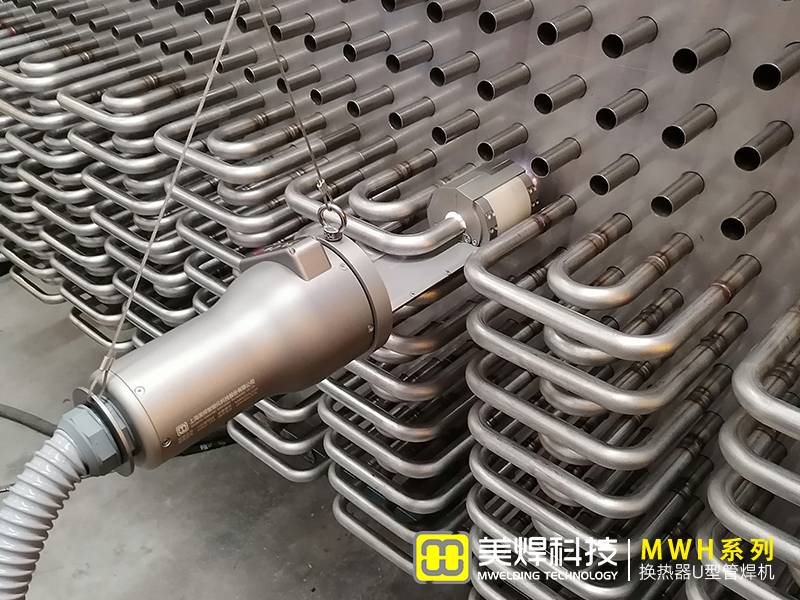

This welder is a "mini expert" specially designed for heat exchanger U-tube welding. With a compact and small body, it can flexibly get into densely packed pipes and accurately align with the welding position. Moreover, it uses imported core components and is equipped with full-body water cooling, making the machine less likely to overheat and damage, with strong durability and few failures even after long-term use.

Easy to operate, labor-saving – one person can operate 2 welding torches

What makes manufacturers most relieved is its "easy to learn and labor-saving" feature. In the past, welding U-tubes required technicians with years of experience, but now even ordinary workers who have never been exposed to welding can learn to operate it after 1 hour of training. When skilled, one worker can even manage 2 welding torches at the same time. This significantly reduces labor costs and simplifies management — no more worrying about technician resignations or new workers failing to keep up.

MWH series heat exchanger U-tube welders applied in large-scale production of heat exchanger factories

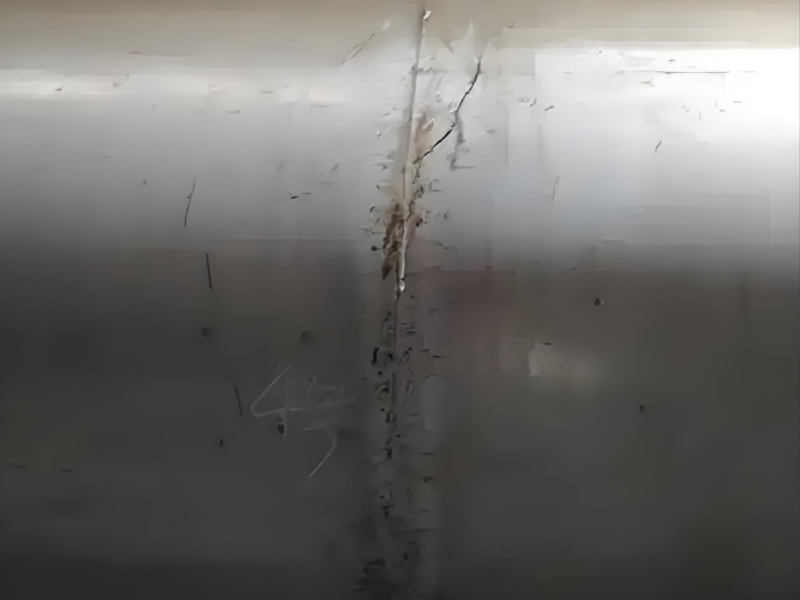

The welding quality is excellent. It comes with an "expert welding parameter library", eliminating the need for workers to repeatedly adjust parameters. The resulting welds are smooth and aesthetically pleasing, achieving the effect of "welding one side, with both sides smooth". Test data shows that when welding 12.7mm thick pipes, the weld can withstand an internal pressure of 550kg, with pressure resistance and impact resistance far exceeding traditional manual welding. Coupled with multi-channel gas protection, it can easily meet the needs of industries with high welding quality requirements, such as heating, ventilation, refrigeration, and surface cooling equipment. Many manufacturers who have used it say that since switching to this welder, rework has been reduced by more than half, production efficiency has increased, product quality has become more stable, and even orders have increased.

Booming shipment of MeiHan heat exchanger U-tube welders – heat exchanger manufacturers, take a look

It has several models for pipes of different thicknesses. Whether it's small 12.7mm diameter pipes or thick 20-25mm U-tubes, there are corresponding models available: for example, MWH-12DA is suitable for 12.7mm pipes, and MWH-25A can weld 20-25mm pipes. You can choose according to your needs.

Applicable pipe diameters:

MWH-12DA suitable for pipe diameter: Φ 12.7mm, insertion wall thickness ≤1.3mm

MWH-16A suitable for pipe diameter: Φ 12.7mm (optional) -16mm, insertion wall thickness ≤1.3mm

MWH-21A suitable for pipe diameter: Φ 19-21mm, insertion wall thickness ≤1.3mm

MWH-25A suitable for pipe diameter: Φ 22-25mm, insertion wall thickness ≤1.3mm

Welding type: U-tube

Customization is also available according to the diameter, wall thickness, U-tube center distance of the U-tube you need to weld.

What's more reassuring is that MeiHan Technology is an experienced enterprise with more than ten years of history, and also a national high-tech enterprise, as well as an ISO9001 and CE certified enterprise. It not only provides welders but also customizes equipment according to the special needs of manufacturers, offering free on-site sampling and on-site test welding. For more information, please call 18918961606 directly or check the official website (https://www.mwelding.com.cn).

For heat exchanger manufacturers, this MWH series U-tube welder is more than just a piece of equipment; it's a "good helper" that helps enterprises reduce costs, increase efficiency, and improve product quality. No more worrying about welding problems or being burdened by high labor costs. It's no wonder that more and more advanced enterprises are choosing it.