In the field of industrial manufacturing, the welding precision and efficiency of core components such as heat exchangers and refrigeration equipment have always been technical difficulties. The MWH-21A heat exchanger U-tube welding equipment launched by Shanghai Meihang Intelligent Technology Co., Ltd. has reconstructed the technical standards for thin-walled metal tube welding with professional design and intelligent control, providing a full-process solution for the welding of carbon steel, stainless steel and other materials.

Equipment Technical Parameters and Application Scenario Adaptation

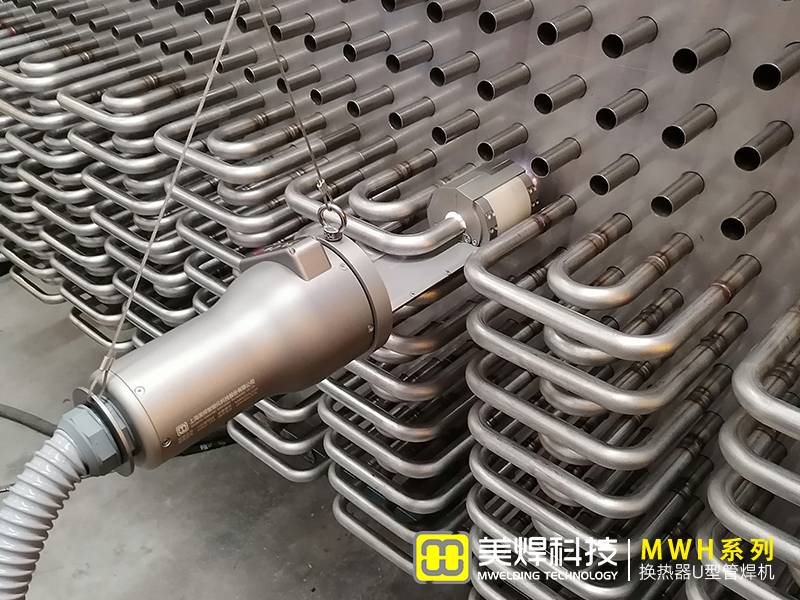

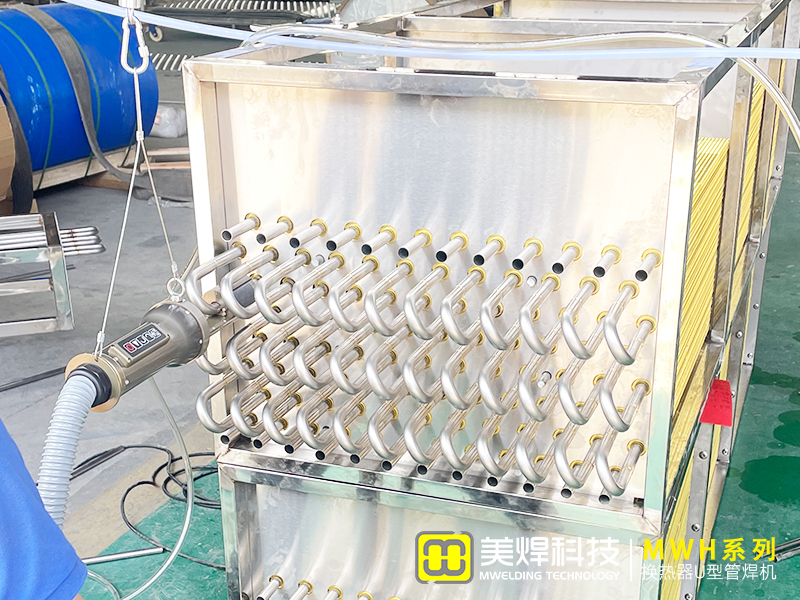

This equipment is specially designed for working conditions where the center distance of end plate openings is 54mm, and the hole positions are arranged in a square or equilateral triangle. The welding pipe diameter covers φ16-21mm, adopting the "weld first then expand" process mode. Key parameter requirements include: the height of the straight pipe extending from the end plate ≥36mm, the length of the U-bend straight line segment ≥44mm, and the insertion depth ≥16mm, ensuring the mechanical stability of the welding structure. The equipment is composed of an MWH-21A welding tongs (approximately 24KG) and an MWA-200 control power supply, with a 6m long cable configuration suitable for complex field environments.

Technical Breakthroughs of the Fully Enclosed Welding System

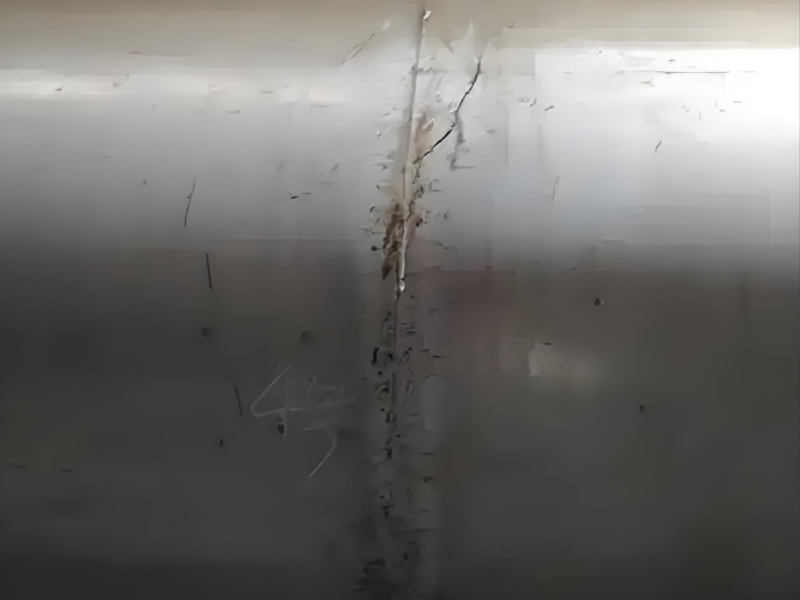

The all-position gas shielding design is the core competitiveness of the equipment: the welding tongs adopt polymer insulating materials and aluminum alloy structures, equipped with an internal directional multi-channel gas shielding system, which not only shortens the inflation time but also achieves high-quality welds with single-sided welding and double-sided formation. The water cooling circulation system greatly improves the equipment's duty cycle, and the hand-held quick-installation fixture realizes rapid positioning within 30 seconds. Combined with the welding method of fixed welding torch and rotating welding tongs, it significantly improves on-site operation efficiency. For easily oxidizable materials such as stainless steel, the equipment supports internal argon shielding of the pipe, eliminating oxidation risks from the process level.

Functional Innovation of Intelligent Control Power Supply

The MWA-200 control power supply is equipped with a 10-inch color touch screen, integrating functions such as one-key parameter printing, 1000-group process storage, and expert system automatic parameter generation. The 8-zone partition control can meet the needs of multi-layer welding processes. The equipment has built-in 6 safety mechanisms such as motor overload protection and water flow detection. The 18KG lightweight design is suitable for high-altitude operation scenarios. Its inverter power supply type and IP21 protection level ensure stable operation under complex working conditions.

Welding Process Specifications and Safety Operation Points

Whether for plug-in or butt joints, the area within 20mm around the weld must be free of burrs and oil stains, with the pipe orifice perpendicularity error ≤±1° and ovality ≤5%. It is specially required that the welded pipe fittings must be reliably grounded, the power supply wiring must be operated by professional electricians in accordance with national standards. The yellow-green grounding wire is strictly prohibited from being omitted, and the use of leakage protection switches is prohibited to prevent tripping.

Technical Value and Industry Application Prospect

Through modular design, intelligent control, and process standardization, the MWH-21A equipment has achieved full-chain optimization from equipment parameter matching to welding quality control. It is not only suitable for industrial scenarios such as heat exchangers and surface coolers but also shows application potential in high-precision fields such as electronics, pharmaceuticals, and military industries. Its technological innovation provides a reproducible standardized paradigm for metal tube welding, promoting the industry's upgrading towards efficiency and intelligence.