Welding is a process that joins metal or non - metal materials together by means of heating, pressure, etc. It has advantages such as high connection strength, good sealing, low cost, and high production efficiency, and is widely used in various industries. However, there are also some problems in the welding process, such as welding deformation, pores, oxidation, cracks, etc., which require strict control and operation of the welding process. In order to improve welding quality, modern industry is increasingly adopting automatic and digital welding equipment and processes, which have greatly improved the accuracy, efficiency and quality of welding.

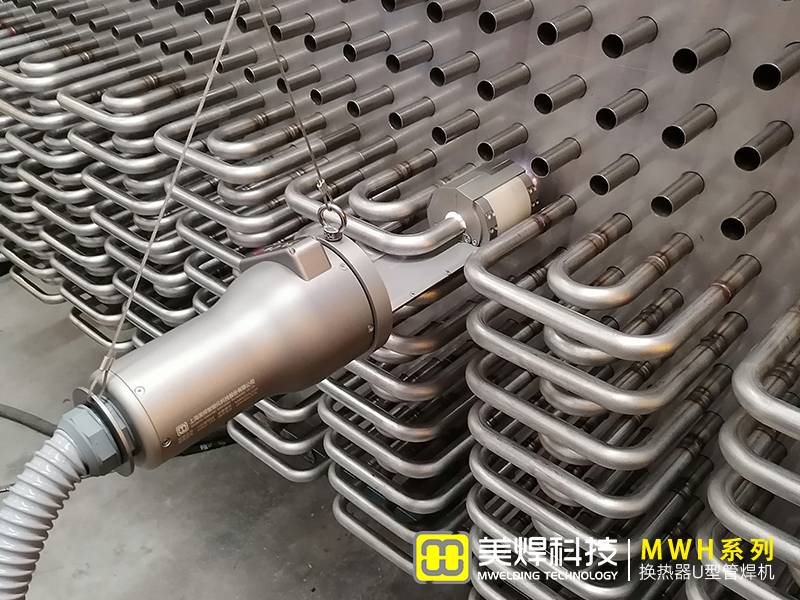

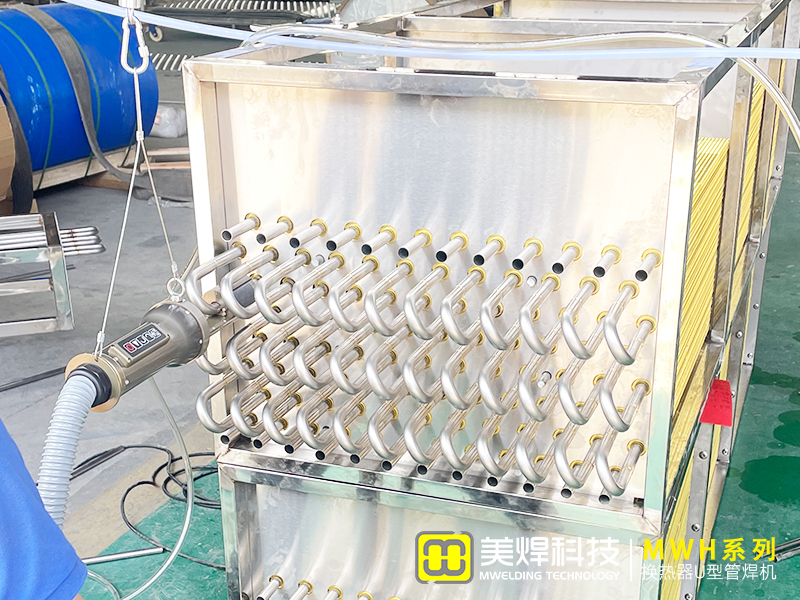

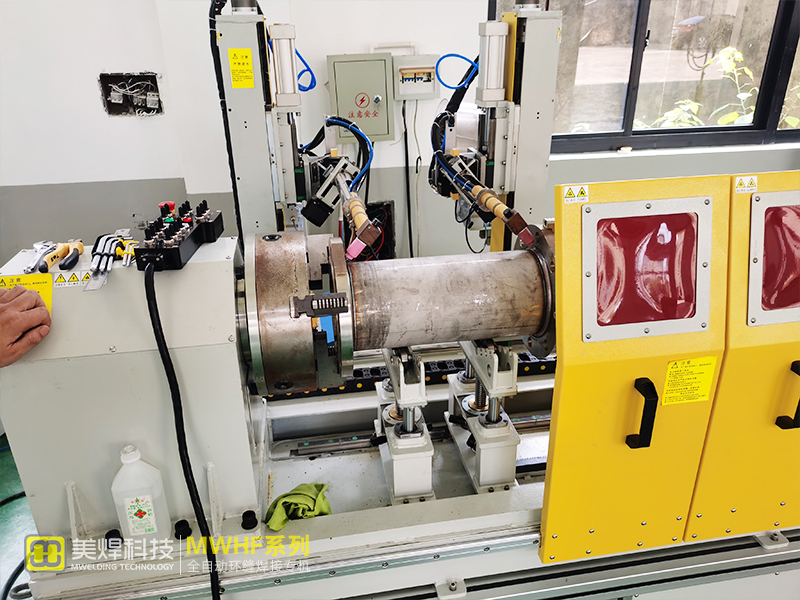

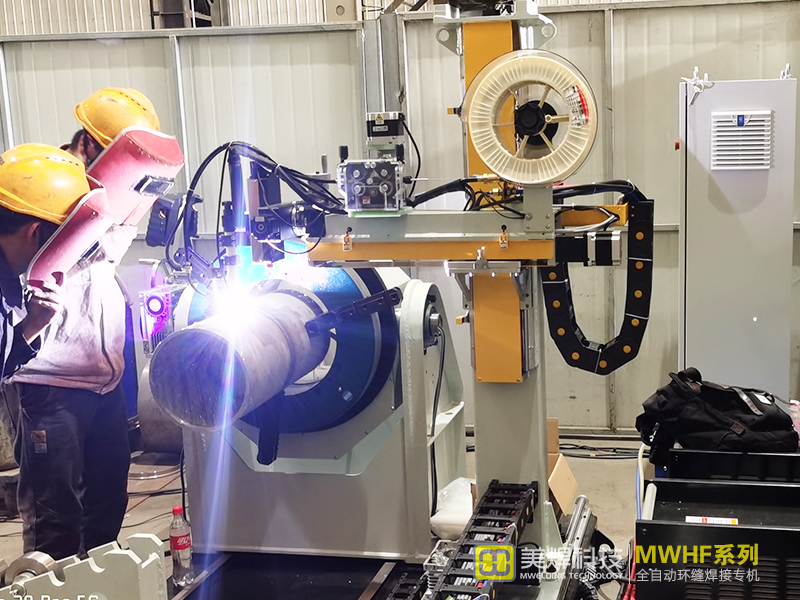

Circular seam welding machines are devices used for welding circular welds. They are widely applied in the welding of pipes and pipe fittings in many fields such as petrochemical, natural gas, food, pharmaceutical, chemical fiber, nuclear power, shipbuilding, etc. Specifically, they are used in the production, processing and connection of straight pipes, elbows, tees, and flanges through butt joint, plug - in, and fillet seam welding.

With the help of advanced computer control technology, high - precision welding can be achieved. Its intelligent adjustment function and automatic protection function can greatly improve welding efficiency and quality, and reduce maintenance costs. Compared with the traditional manual welding method, automatic circular seam welding machines have significant effects in ensuring welding quality, improving uniformity, reducing labor input, and lowering labor intensity. They are easy to operate and learn, enabling even beginners to perform high - quality welding. They can greatly improve the comprehensive competitiveness of enterprises and are one of the indispensable equipment for modern enterprises.

According to different welding processing requirements, the structure and process of the MWHF series circular seam welding equipment can be customized on demand. Vertical automatic circular seam welding machines, horizontal automatic circular seam welding machines, and edge beam type automatic circular seam welding machines are equipped with various welding process systems such as TIG (with or without wire filling), MIG, MAG, PAW, etc., which can flexibly adapt to the business needs of multiple scenarios.

The mini automatic circular seam welding machine is adjusted in structure and function on the basis of the standard circular seam welding machine, making its volume smaller and the structure more compact and intensive. It is especially suitable for the precision welding needs of small and medium - sized pipe fittings, occupies less space, and is more flexible to use.

Customized special welding equipment will be built according to the actual welding production needs to meet the requirements of automatic circular seam welding machines. The shape, size and width may vary. Vertical circular seam welding machines are mostly used for circular seam welding of some short and small workpieces; Horizontal circular seam welding machines have less restriction on the length of workpieces. The end of the main shaft is equipped with welding fixtures or three - jaw chucks for clamping and positioning workpieces, which can easily weld pipes of 3 meters or 6 meters; Combined with the welding operation frame, the automatic circular seam welding equipment can effectively expand the moving range in the horizontal and vertical directions, and is suitable for longitudinal and circular seam welding of cylindrical workpieces such as medium and large pressure vessels and petrochemical containers;

Automatic welding machines conform to the trend of the times and have incomparable advantages in welding efficiency, quality assurance, welding uniformity, and intelligent digital management. More and more enterprises are exploring and releasing more production potential through changes in this aspect. When purchasing equipment, it is recommended to start from the actual situation of their own production line equipment and welding needs, seek and compare schemes from multiple manufacturers, combine the application examples of manufacturers' welding equipment, and implement the details of equipment application for customized production. Combined with the characteristics of welding operations in the industry and enterprises and the existing equipment production lines, the functions of the welding system can be increased, reduced or extended to meet the welding needs of production, manufacturing and processing in a targeted manner. At the same time, according to the requirements of the production process, the equipment modules can be flexibly adjusted to ensure welding quality while improving production efficiency. In addition, the equipment can be put into production immediately after purchase, which is closely integrated with all links of production, with quick results and convenient maintenance and management in the later stage.

MeiHan Technology has been rooted in the field of pipe welding for decades, with leading technology, sophisticated manufacturing, excellent service, and welding thousands of customers. With innovative technical strength and long - term market application experience, the own technical support team provides customers with one - to - one customized welding services, full - process welding operation guidance, rapid response after - sales service, welding system optimization and upgrading, regular product maintenance, automatic equipment rental and other preferential value - added services. Starting from the customer's perspective, we go deep into the upper, middle and lower sections of the business process, and play the role of professional supporters of welding technical services to explore and create new value for customers.

From standardized to non - standard welding equipment, and from professional welding equipment suitable for small - diameter pipes in instruments to large - diameter pipes in petrochemical industry, MeiHan series products complement each other and meet the market demand in the field of pipe welding. Special welding equipment is widely used in high - end manufacturing fields such as instruments, food and pharmaceutical machinery, air conditioning and refrigeration, energy boilers, water treatment and environmental protection, engineering machinery, petrochemical industry, aerospace, military industry, nuclear power, etc.

Because of focus, so excellence! The company adheres to the business philosophy of "putting customers at the center, customizing according to needs, and integrating services without outsourcing", upholds the corporate culture concept of "Beauty in action, welding without trace, science serving the country, and technology without boundaries", adheres to the corporate mission of "helping customers and employees succeed", promotes the corporate values of "integrity, friendship, dedication, and pragmatism", strives to build a high - end brand of automatic welding equipment, and continuously provides customers with high - quality welding equipment products that can bring orders, technical solutions, and high - value - added services. Make its own contribution to the strength of Made in China!

Scope of application of MeiHan MWHF series automatic circular seam welding machines:

Product scope of application: length within 12.5m; diameter 20mm - 500mm;

Welding types: pipe - to - pipe welding, pipe - to - tee welding, pipe - to - flange welding;

Welding power supply can be optional: Fronius (Austria), EWM (Germany), Panasonic (Japan), etc;

Main control system can be optional: Mitsubishi (Japan), BECKHOFF (Germany), etc;

Product advantages of MeiHan MWHF series automatic circular seam welding machines:

1. The product is equipped with a high - speed hydraulic power chuck, which enables quick loading and unloading of workpieces and convenient operation;

2. The product adopts a variety of control output signal selections and output interfaces according to process requirements;

3. Equipped with a circulating water cooling system, it can work for a long time continuously;

4. A perfect gas protection system ensures good protection of the molten pool during the welding process;

5. The whole machine adopts a quick disassembly and assembly modular design, which is convenient for maintenance and installation;

6. The product has the characteristics of strong anti - interference, high reliability, and stable speed regulation;

The equipment adopts a stainless steel frame structure, which can meet the load - bearing requirements of the whole machine. The overall design of the appearance is light and compact, with quick installation, convenience and practicality, and is easy for subsequent maintenance and repair. The welding machine motor and welding control system both adopt imported equipment and software, with one - to - one customized welding technical schemes, coupled with perfect full - process technical services, so that you can have no worries in the later stage.

MeiHan Technology's pipe welding equipment products and services have undergone decades of market testing and won unanimous praise from customers! Customer satisfaction is the greatest support for us! MeiHan thanks you for your trust and is committed to providing you with services!

For more products and services such as automatic pipe - to - pipe welding machines, automatic pipe - to - plate welding machines, automatic circular seam welding machines, hot wire surfacing systems, please call: 18918961606 or visit the official website of "Shanghai MeiHan": http://www.shmeihan.com/, WeChat official account, and video account for more information;

Shanghai MeiHan Intelligent Technology Co., Ltd. is a national high - tech enterprise, passing the ISO9001 quality system certification. It specializes in the production of automatic pipe - to - pipe welding equipment, automatic pipe - to - plate welding equipment, automatic circular seam welding machines, hot wire surfacing systems and integrated welding control power supplies. Adhering to the business philosophy of "being customer - oriented, customizing according to needs, and integrating services without outsourcing", the company strives to build a professional high - end brand of pipe welding equipment, and continuously provides customers with high - quality welding equipment products that can bring orders, technical solutions and high - value - added services.