In the welding production operations of heat exchangers, condensers, and header pipes, do you often encounter many troubles? For example, the product's pipe connections are not as smooth and beautiful as those of your peers, lacking market competitiveness; the team's operational capabilities are limited, leading to unstable welding quality; production costs remain high, affecting corporate efficiency. In fact, these problems are not unsolvable. Leading enterprises in the industry have already found a breakthrough, and the answer lies in MeiHan Technology's MWH series heat exchanger U-tube welding machine.

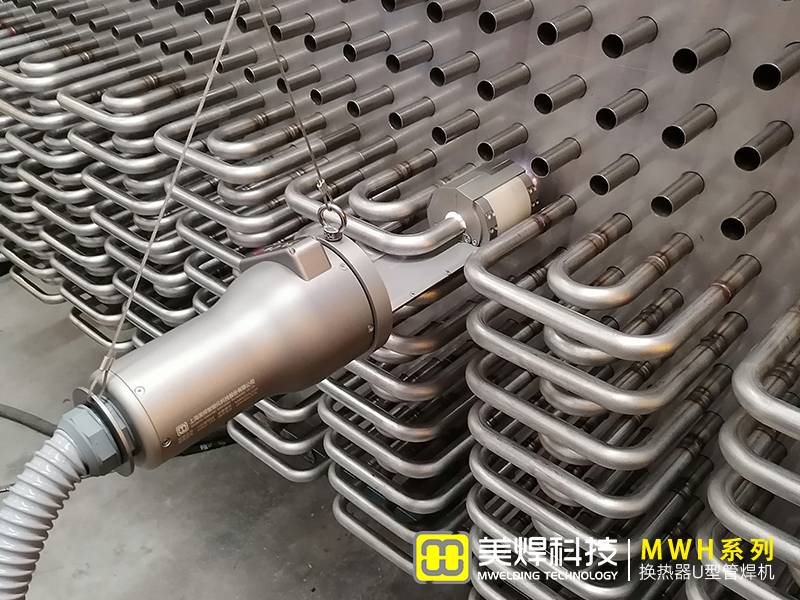

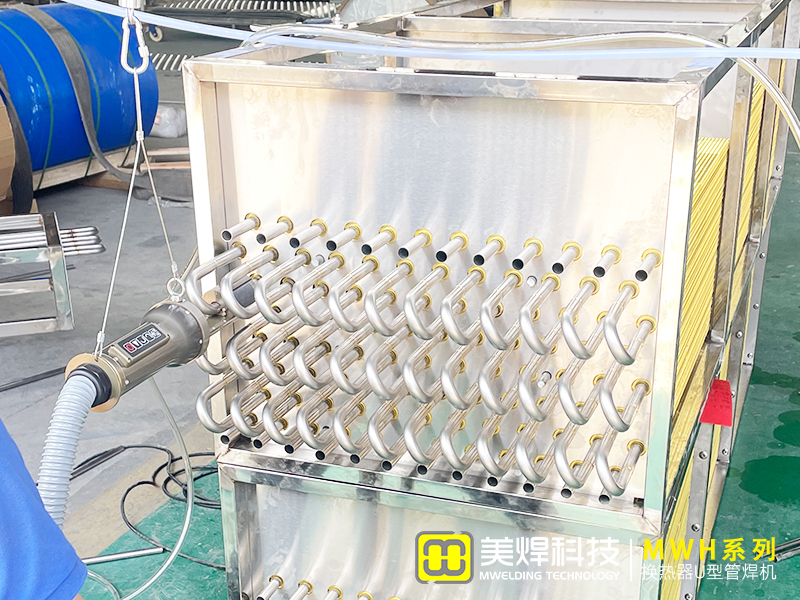

The MWH series heat exchanger U-tube welding machine developed by MeiHan Technology is a proprietary equipment with independent intellectual property rights. It is specially customized for the welding of U-tubes in heat exchanger equipment and can accurately solve the bottlenecks in industrial production welding. This series of equipment adopts imported core components, with a lightweight structure, and has the advantages of safety, precision, durability, and reliability. The full-body water-cooling design effectively improves the duty cycle of the welding torch and ensures the stable operation of the equipment for a long time.

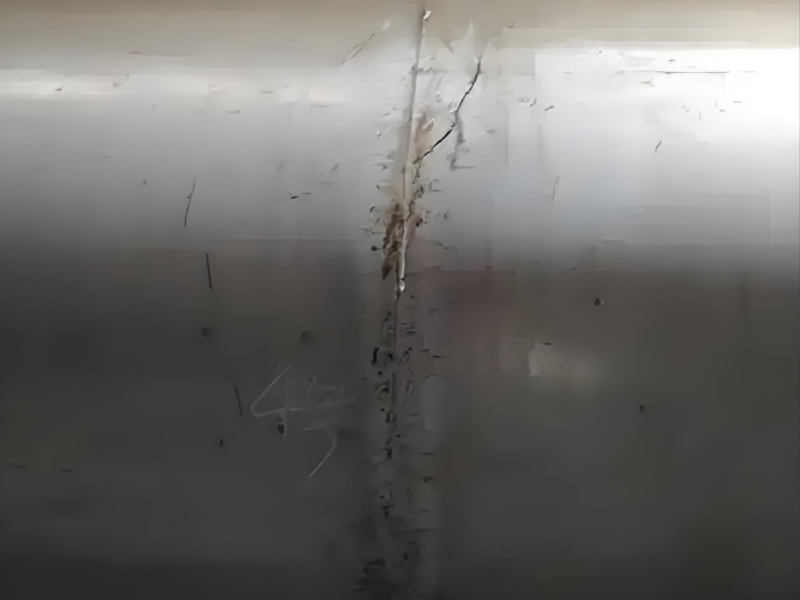

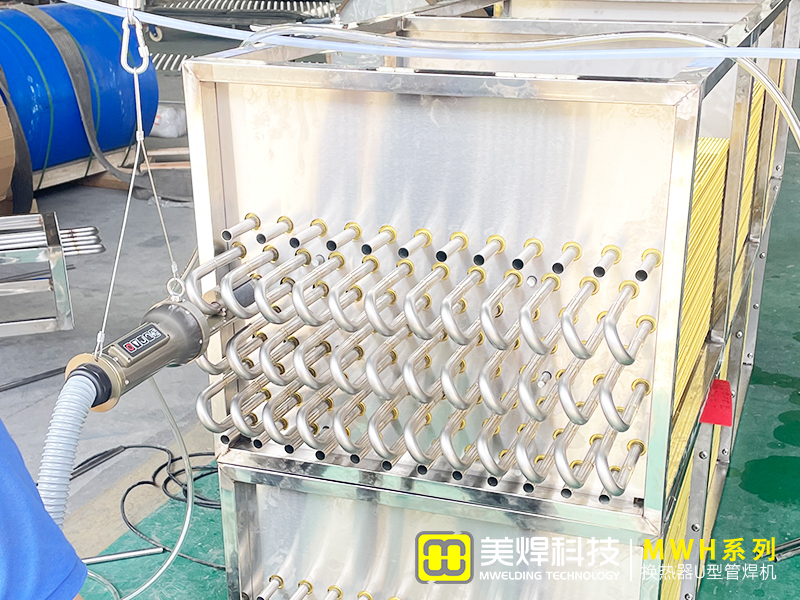

It adopts the argon arc self-fusion welding process, combined with a digital intelligent welding control system, which can realize automatic quality welding without wire addition and manual intervention. This feature fundamentally avoids common problems in manual operations, such as unreliable wire 搭接,insufficient coverage, undercut, uneven weld cladding, etc. These problems often lead to low weld quality, failure to pass pressure resistance tests, easy leakage, damage, and other situations.

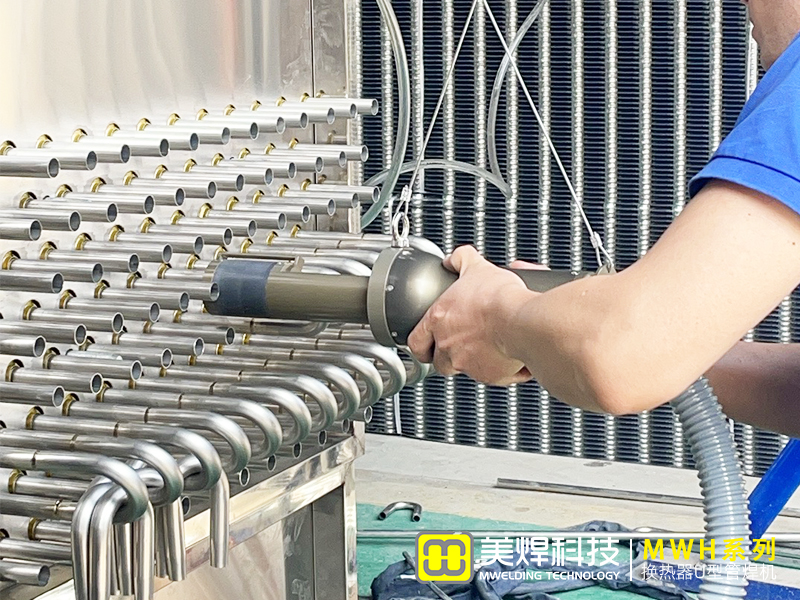

The MWH series equipment also has many user-friendly designs: the compact and miniaturized body can flexibly enter dense pipe arrays; digital standardized welding parameters can be conveniently stored, managed, and printed; the operation mode is a simple button type, and workers with zero foundation can learn to operate in only 1 hour. After several hours of training, ordinary workers can also quickly weld qualified and high-quality welds. In the later stage, one person can operate 2 welding torches at the same time, greatly improving labor efficiency and reducing labor costs.

In terms of welding quality, the equipment is equipped with multi-channel gas protection, ensuring that the welding quality fully meets the requirements of the surface cooling equipment industry, far exceeding the level of traditional pipe-pipe welding. It can greatly demonstrate the excellent craftsmanship and quality of products and improve product grades.

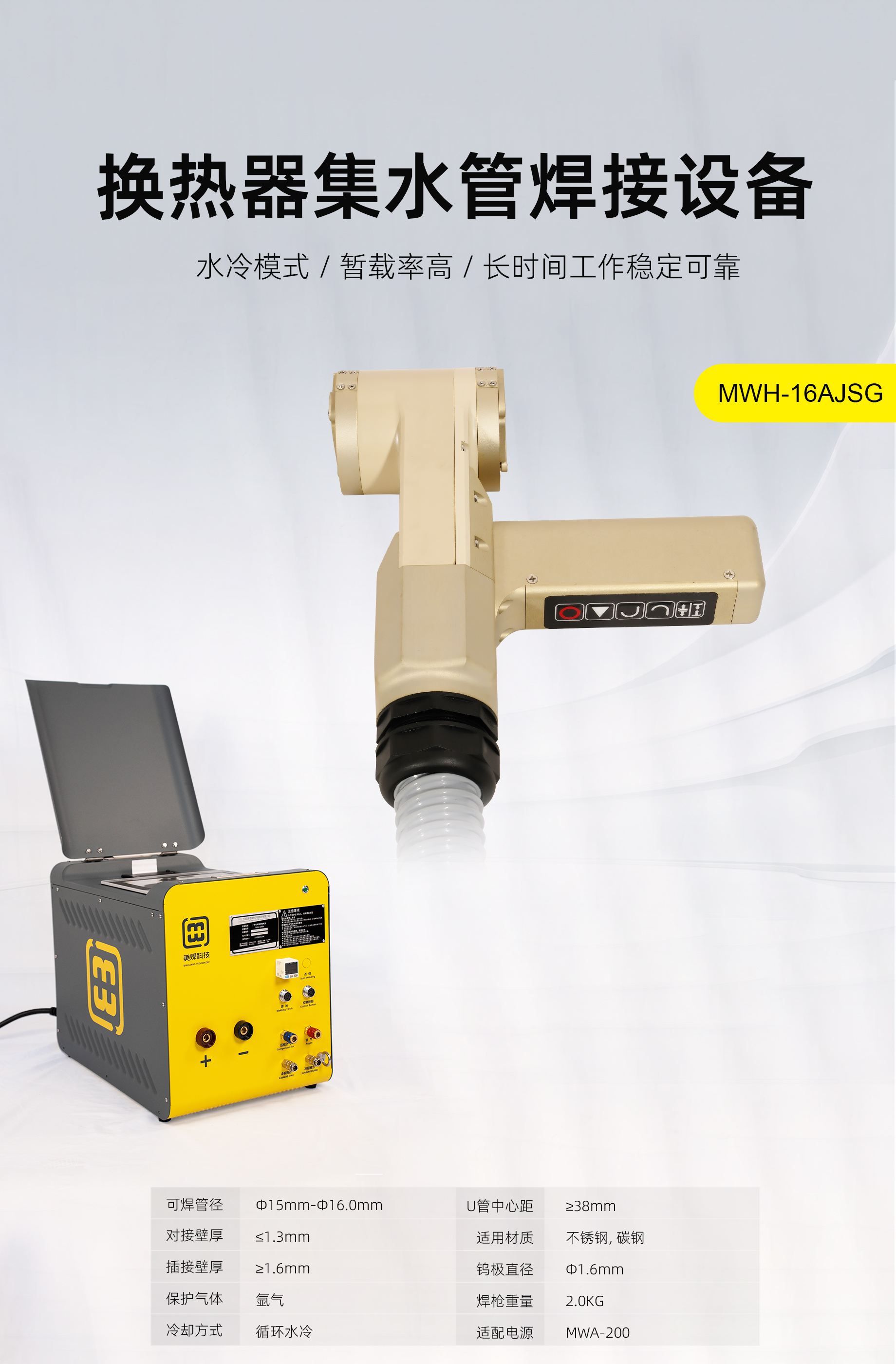

This series of equipment has multiple models to choose from for different pipe diameters:

MWH-12DA is suitable for pipe diameter: Φ12.7mm, wall thickness ≤1.3mm

MWH-16A is suitable for pipe diameter: Φ12.7mm (optional) -16mm, wall thickness ≤1.3mm

MWH-16AJSG is suitable for pipe diameter: Φ12.7mm (optional) -16mm, wall thickness ≤1.3mm

MWH-18A is suitable for pipe diameter: Φ18mm, wall thickness ≤1.3mm

MWH-21A is suitable for pipe diameter: Φ19-21mm, wall thickness ≤1.3mm

MWH-25A is suitable for pipe diameter: Φ22-25mm, wall thickness ≤1.3mm

Many customers who have used MeiHan MWH series equipment feedback that the equipment has stable welding effect, beautiful weld formation, and high welding efficiency. Compared with manual welding, the rework rate is significantly reduced, and the efficiency is significantly improved; moreover, the operators have changed from technician-level welders to general workers, which greatly reduces labor costs and makes management more convenient. For U-tube welding in the HVAC and refrigeration industry, the MWH series equipment is undoubtedly an excellent choice, helping enterprises improve production efficiency and product quality, thereby bringing more orders.

Shanghai MeiHan Intelligent Technology Co., Ltd. is a national high-tech enterprise and an ISO9001 certified enterprise, focusing on the R&D and manufacturing of automatic pipe welding equipment for decades. The company's products include fully automatic pipe-pipe welding equipment, fully automatic tube-sheet welding equipment, automatic circumferential seam welding machines, hot wire surfacing systems, and welding control power supplies, and provide integrated services. The equipment adopts German imported components, which are precise, efficient, durable, easy to operate, and cost-effective. It also supports industry customization and provides full-process technical services.

The company adheres to the business philosophy of "everything is customer-oriented, customized according to needs, and integrated services are not outsourced", and is committed to building a high-end brand of professional pipe welding equipment, continuously providing customers with high-quality welding equipment that can bring orders, technical solutions, and high-value-added services.

If you have requirements for welding quality, efficiency, and production operation management in heat exchanger manufacturing, MeiHan Technology's automated welding production mode will open a new welding realm for you. Shanghai MeiHan Technology provides customers with free proofing or on-site trial welding services. For more automated pipe-pipe welding machines, automated tube-sheet welding products and services, please call 18918961606 or visit Shanghai MeiHan's official website: https://www.mwelding.com.cn.