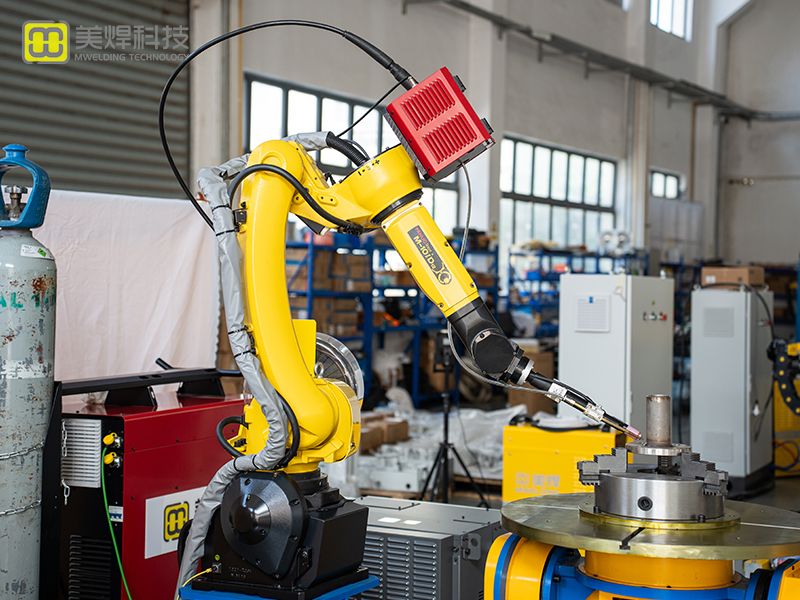

A quiet yet profound technological revolution is unfolding in the field of industrial welding. The eight-axis TIG welding robot technical solution introduced by Shanghai Meihang Intelligent Technology Co., Ltd. breaks the spatial constraints of traditional welding with its innovative architecture of "six-axis robot + two-axis positioner", bringing double breakthroughs of "millimeter-level precision + intelligent production" to high-end manufacturing. It is like a precision industrial cutter redefining the boundaries of welding processes.

Founded in 2012, Shanghai Meihang Intelligent Technology Co., Ltd. is a national high-tech enterprise focusing on R&D, manufacturing, sales, and integrated after-sales services for full-position automatic pipe welding equipment, integrated welding control power supplies, automatic welding equipment, welding robot complete sets, and 3D printing intelligent manufacturing processes. Located in Songjiang, Shanghai, along the G60 Science and Innovation Corridor in the Yangtze River Delta—one of China's most economically dynamic regions—the company relies on advanced innovative patent technologies, high-quality automatic welding equipment, and multi-faceted welding technical support services to provide customers with one-stop services from automatic welding demand analysis to equipment delivery and training.

I. Multidimensional Linkage: Eight-Axis Architecture Cracks the Code of Welding Space

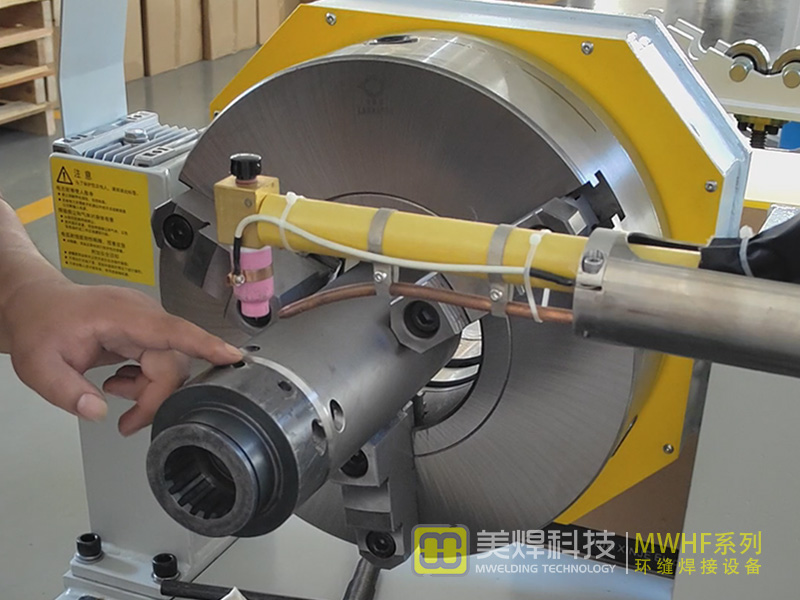

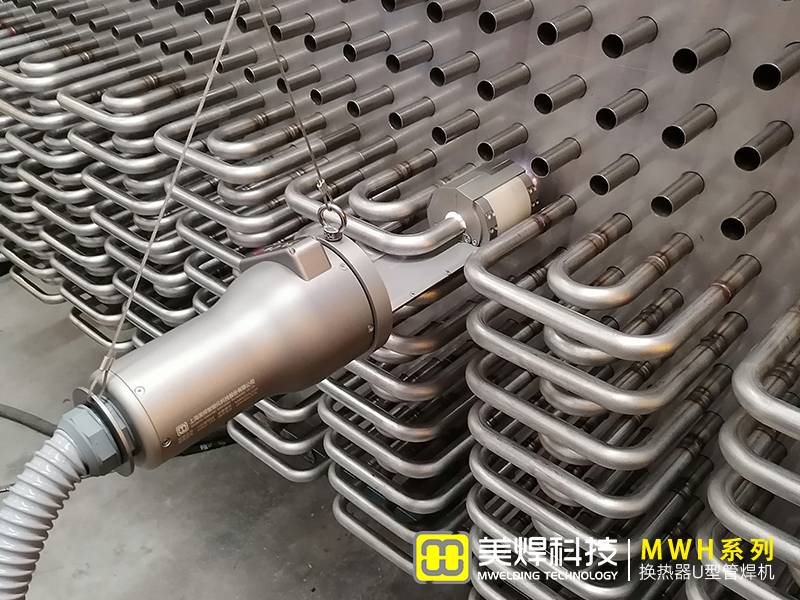

Traditional six-axis robots often suffer from uneven weld formation due to postural limitations when facing complex curved surface welding. This solution innovatively links the FANUC M-10iD/12 six-axis robot with a two-axis P-type positioner to form an eight-axis collaborative system. The 500kg load positioner can achieve ±185° flipping and ±370° rotation. Combined with the robot's ±0.03mm repeat positioning accuracy, it ensures that the tungsten electrode maintains the optimal welding angle with the workpiece.

The integration of the Hot Wire TIG process is the finishing touch. The HW-500E program-controlled power supply has built-in AC/DC hot wire functions. By preheating the welding wire through pulse heating, the deposition rate is increased by 60%, the welding speed is doubled, and the dilution rate is reduced by 60% under the same current. This dual-drive mode of "arc melting + hot wire filling" is like installing a turbocharged engine for the welding process.

II. Intelligent Core: The Leap from "Manual Teaching" to "Adaptive Control"

The soul of this technical solution lies in its intelligent control system. Based on a Mitsubishi PLC central processor and matched with FANUC robot motion control software, it constructs a fully digitized welding brain. The AVC arc voltage tracking function real-time samples voltage signals to dynamically correct the welding trajectory; the contact lifting function allows the tungsten electrode to automatically lift in the coordinate system direction after touching the workpiece to avoid collision damage.

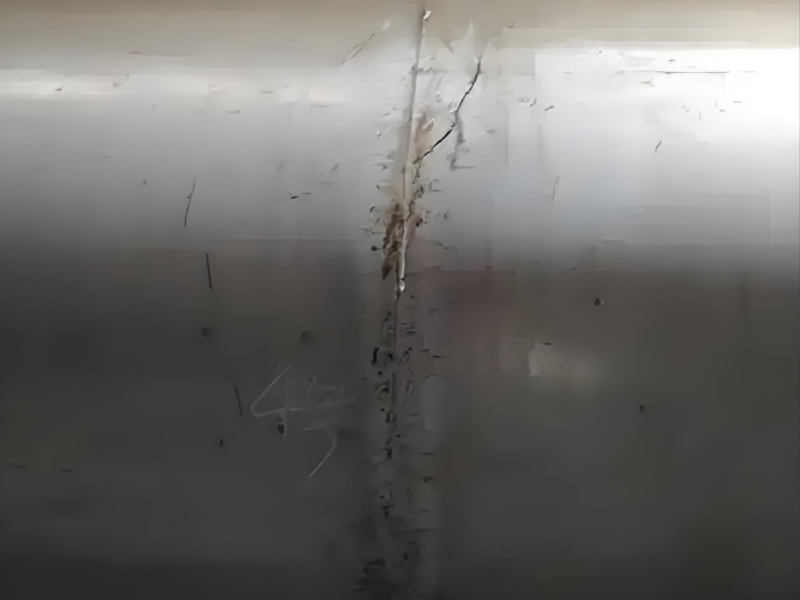

The human-machine interaction system composed of a handheld control panel and a color teaching pendant greatly reduces the operation threshold. Operators can call 50 sets of preset process recipes with one key and adjust parameters such as current and wire feeding speed in real time during welding. The (wobble) function provides various modes such as Z-type and O-type. Combined with pulse wire feeding, it makes the weld surface as smooth as a mirror.

III. Full-Chain Empowerment: Value Reconstruction from Core Components to Industrial Ecosystem

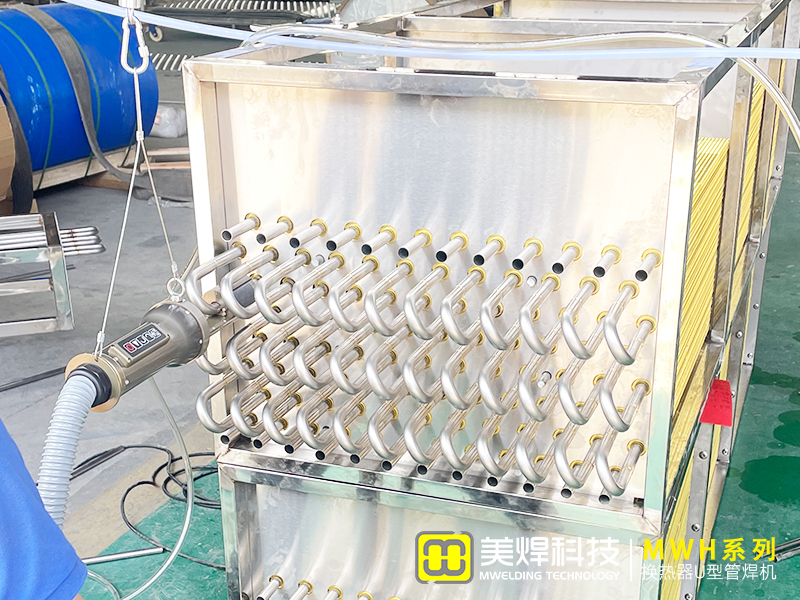

In nuclear power equipment welding, the nine-axis linkage system coordinates with laser vision to achieve precise welding of air guide plates; in the construction machinery field, the eleven-axis linkage solution is compatible with complex welds of 950-type buckets. This design of "modular hardware + flexible software" enables the eight-axis TIG welding robot to excel in high-endmanufacturing scenarios such as aerospace and marine engineering equipment. From an industrial perspective, the value of this technical solution is not only in the equipment itself. Shanghai Meihang provides a complete industrial service ecosystem through the full-cycle services of "installation-commissioning-training" and a 12-month quality guarantee (3 months for welding torches). When the mechanical arm of the eight-axis robot moves precisely in the workshop, it epitomizes the transformation of the entire manufacturing industry towards intelligence and flexibility.

The emergence of the eight-axis TIG welding robot is not only an upgrade of welding technology but also an innovation of industrial thinking. It replaces manual experience with the precision of mechanical arms and reconstructs process standards with digital codes, writing a new chapter of China's intelligent manufacturing breakthrough in millimeter-level welding accuracy. This may be the best footnote to the Industry 4.0 era—breaking boundaries with technological courage and expanding the path of industrial upgrading.