On Demand Customization

About Us

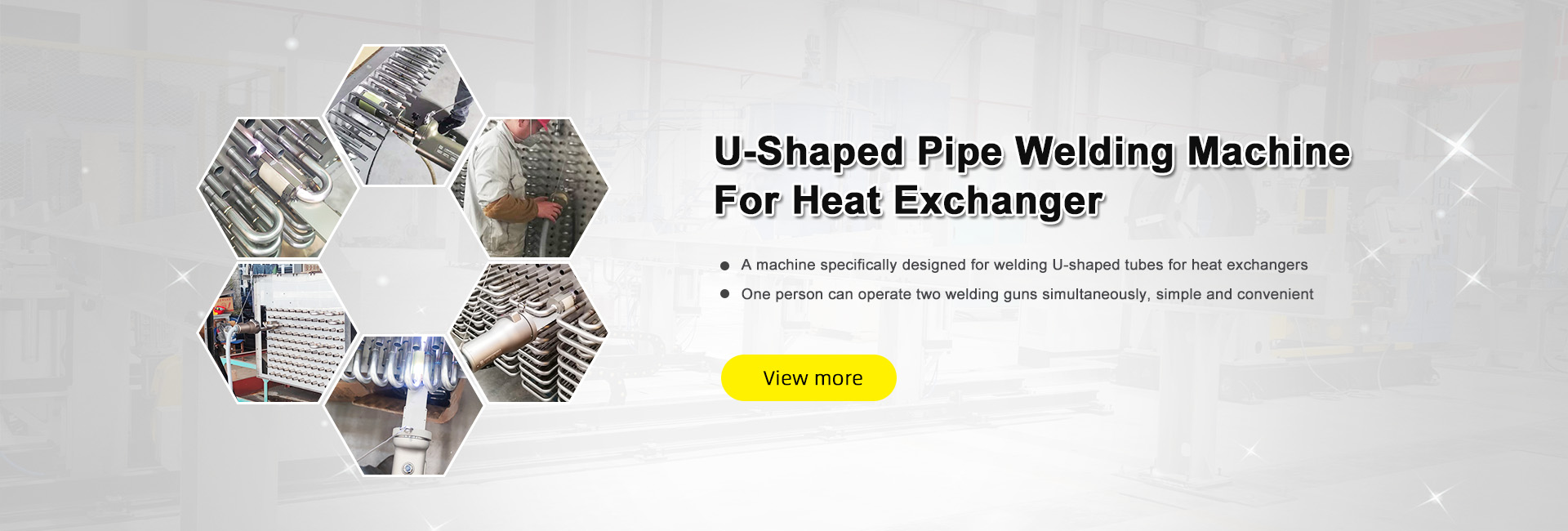

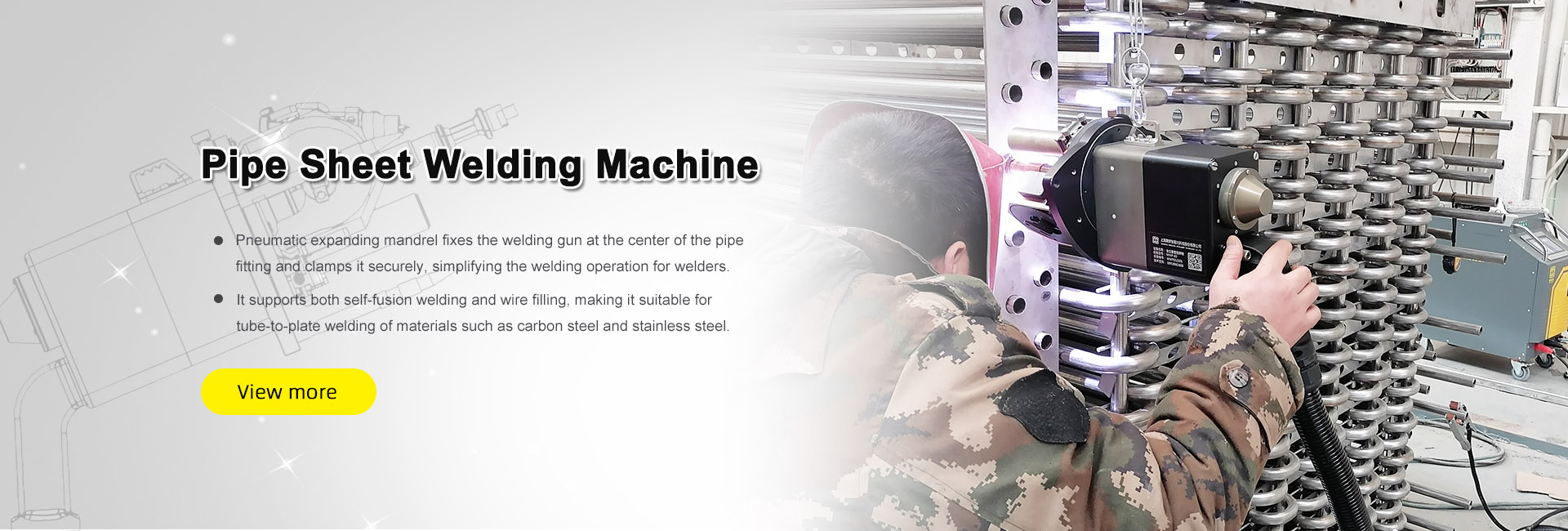

Shanghai MWelding Intelligent Technology Co., Ltd. was established in 2012, focusing on the production of fully automated pipe welding equipment, automated specialized welding equipment, and integrated welding control power supply as a technology-based innovative technology enterprise. The company adheres to the business philosophy of "customer-oriented, customized, and integrated services without outsourcing", focusing on innovative research and development, processing and production, marketing, and after-sales service. We continuously innovate and optimize our research and development, providing customers with comprehensive technical solutions and high value-added services. Technological innovation is the core competitiveness of MWelding Technology. Our main products include heat exchanger U-shaped tube welding machines, open tube automatic welding machines, closed tube welding machines, tube plate automatic welding machines, integrated welding control power supplies, ...