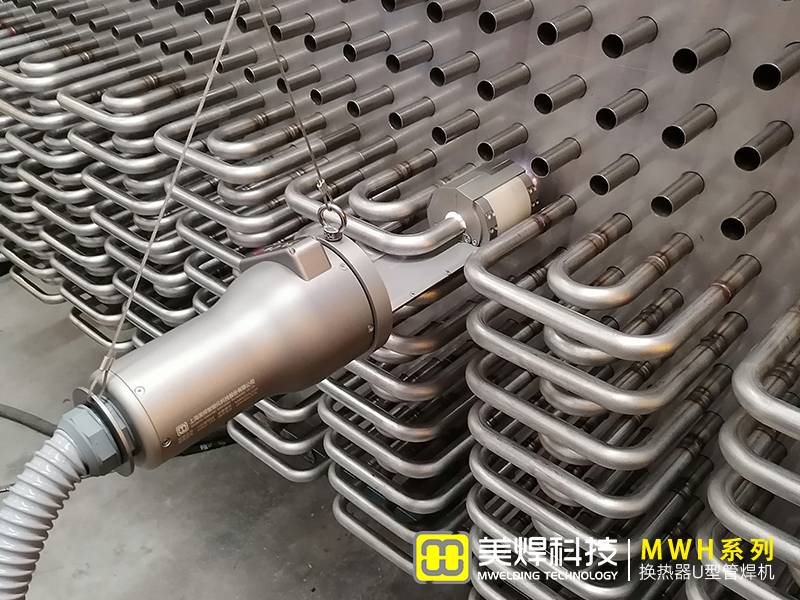

In the field of pipeline welding, the welding of stainless steel elliptical pipe fittings has always been quite challenging. Traditional welding methods not only consume a large amount of manpower and time but also make it difficult to ensure the welding quality. The emergence of the MWG series of open pipe welding machines by Meihan has completely changed this situation.

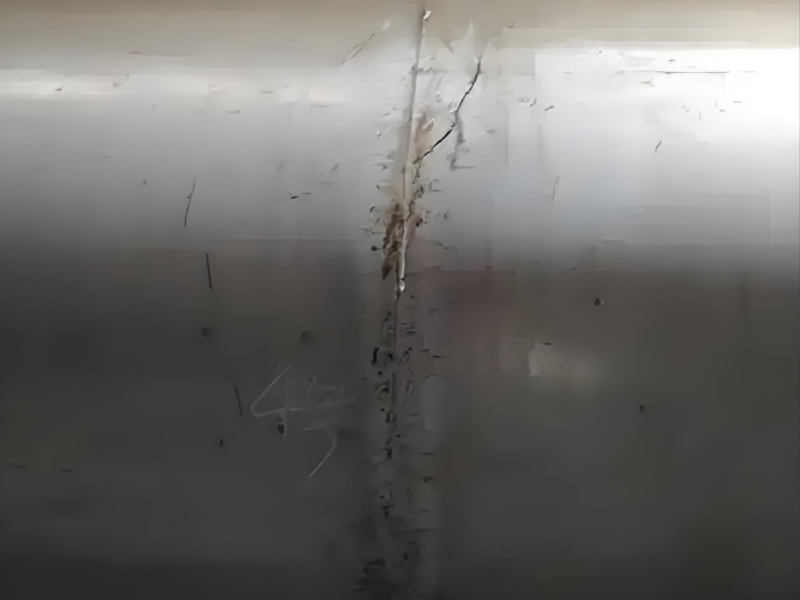

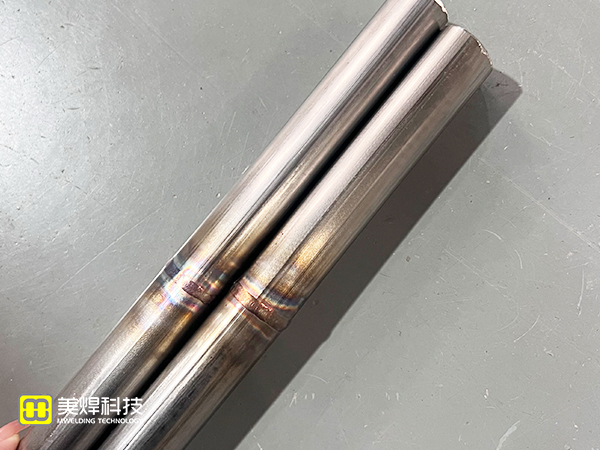

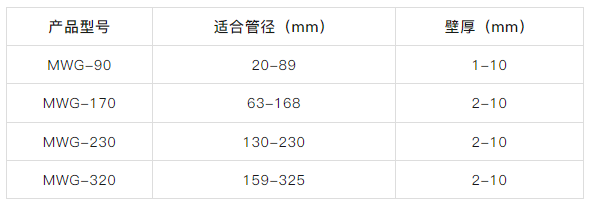

The MWG series is specifically designed for the welding of medium and thick-walled pipelines made of stainless steel, carbon steel, titanium alloy, etc., with a wall thickness of 1-10mm, and it can easily handle stainless steel elliptical pipe fittings. The intelligent digital welding control system it is equipped with can be regarded as the "intelligent brain", which has the functions of automatic arc length, transverse oscillation and welding speed measurement feedback. During the welding process, the system adjusts the parameters in real time to ensure stable welding, uniform and beautiful weld seams, excellent one-time forming effect, and it can easily meet the Class II flaw detection requirements, greatly reducing the subsequent rework cost.

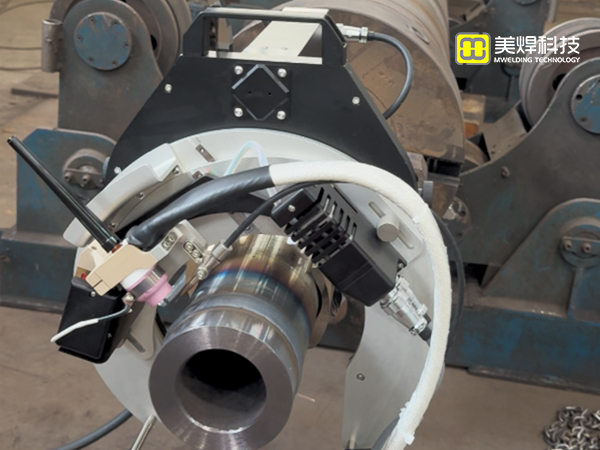

In terms of operation, the MWG series is extremely simple. The stepless adjustable caliper-type fixture can quickly and accurately clamp elliptical pipe fittings of different pipe diameters. Operators can get started without complex training, which significantly reduces the dependence on the skill level of welders and saves labor costs. Moreover, the equipment adopts a gear transmission structure design without gaps, which ensures smooth rotation and a small moment of inertia, guarantees a smooth welding process, avoids adverse phenomena such as jamming, and further improves the welding efficiency.

In practical applications, the MWG series has performed excellently in both pipeline connections in petrochemical projects and the welding of pipe fittings in pressure vessel manufacturing.

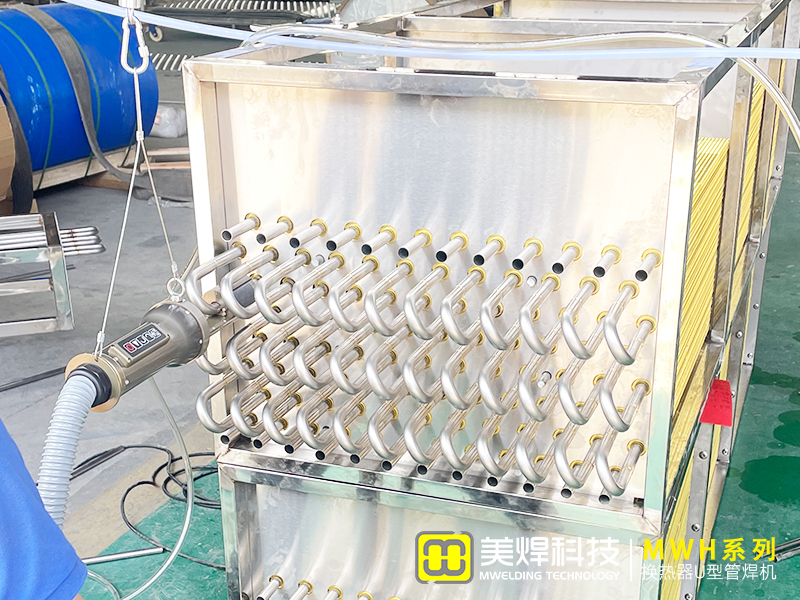

The pipe-to-pipe welding equipment of Meihan is a high-efficiency and high-quality automatic welding equipment, which is widely used in fields such as pipeline installation, petrochemical industry, energy and power, boiler and chemical industry. It is mainly used for the welding of medium and thick-walled pipelines made of stainless steel, carbon steel, titanium alloy, etc. It adopts computer digital control and is equipped with an expert welding database for pipe-to-pipe automatic welding, enabling operators to quickly get started and achieve the best welding results. The equipment has the functions of automatic arc length, transverse oscillation and welding speed measurement feedback, with good forming, and the weld seams meet the Class II flaw detection requirements.

As a convenient standardized operation tool, the pipeline automatic welding equipment, with the help of a 360-degree rotating welding tongs and matched with an automatic welding intelligent control system, can well achieve the argon arc welding operations of backing, filling and capping around the pipeline without the need for the pipe fittings to move. Under the premise of confirming the process parameters, the convenient storage, call, recording and printing management of welding parameter programs greatly facilitate the welding operation management and provide a uniform and reliable guarantee for the stable output of high-quality weld seams.

The MWG series of pipeline automatic welding machines by Meihan is committed to demonstrating superior performance and price. With patented technologies and German component processes, it has been on the market for decades and is widely used in fields such as energy and power, boiler and chemical industry, oil pipelines, pressure vessels, and pipeline installation.

The whole machine adopts a modular design, which is ingenious and compact in structure. The scientifically and reasonably designed stepless adjustable caliper-type fixture fully meets the clamping requirements of pipe diameters within the equipment coverage range, effectively ensuring the coaxial operation of the pipe and the welding trajectory. It has the functions of automatic arc length and transverse oscillation control. It can achieve single-sided welding with double-sided forming for the backing welding of tungsten inert gas welding, and the pass rate of Class II weld seams in radiographic inspection or ultrasonic inspection is over 98%. It meets the requirements of physical performance tests such as pressure tests, impact, tension and bending tests.

Meihan thanks you for your trust and support and is dedicated to providing you with services!

For more products and services such as automatic pipe-to-pipe welding machines, automatic pipe-to-plate welding machines, automatic circumferential seam welding special machines, hot wire surfacing systems, etc., please call 18918961606 or visit the official website of Shanghai Meihan: https://www.shmeihan.com/