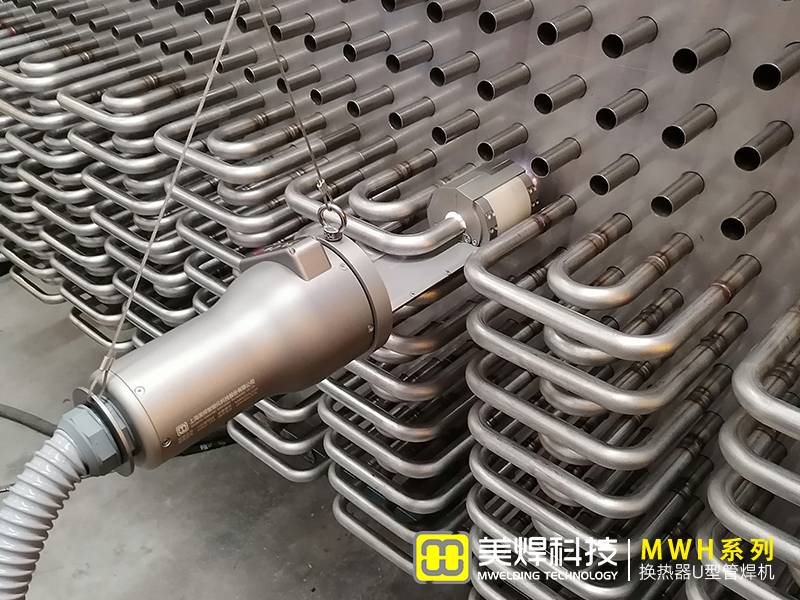

In the manufacturing process of heat exchangers, condensers, evaporators and other equipment, the welding quality of U-tubes directly affects the performance and service life of the equipment. As a custom machine specially designed for this scenario, MeiHan Heat Exchanger U-tube Welder MWH Series has become a powerful assistant in the production of related industries with its unique design and excellent performance.

Core Performance and Application Range

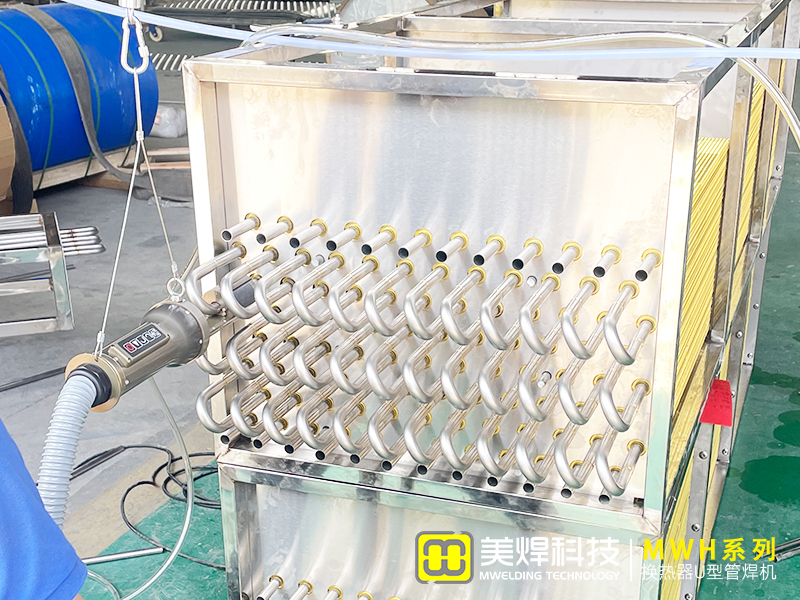

This welder adopts the fusion welding method, which can meet the welding needs of heat exchanger U-tubes made of stainless steel, carbon steel and other materials, and can easily handle both plug-in and butt welding forms. It is suitable for pipe diameters ranging from Φ12.7mm to 25mm, with a U-tube center distance of ≥38mm and a tungsten electrode diameter of Φ1.6mm. It is used in conjunction with the MWA-200 integrated control power supply, which can accurately adapt to related welding operations.

Product Advantages Highlight Competitiveness

Customized Design: Specifically built for heat exchanger U-tube welding, with both structure and functions closely tailored to the special needs of such welding operations, making the welding work more targeted.

Efficient Cooling and Protection: The interior of the welding torch is fully water-cooled (circulating water cooling), which greatly improves the duty cycle of the welding torch and avoids the impact of overheating on the operation. At the same time, the welding torch uses multi-channel gas protection (with argon as the shielding gas), effectively isolating air interference and significantly improving welding quality.

Convenient and Efficient Operation: One person can operate 2 welding torches at the same time, simplifying the operation process and saving labor costs. Equipped with a cylinder clamping device, it can quickly stabilize the workpiece and improve production efficiency.

Reliable and Durable: Using imported core components and materials, while ensuring the durability of the equipment, it also ensures the reliability, safety and precision during operation, providing a guarantee for long-term stable production.

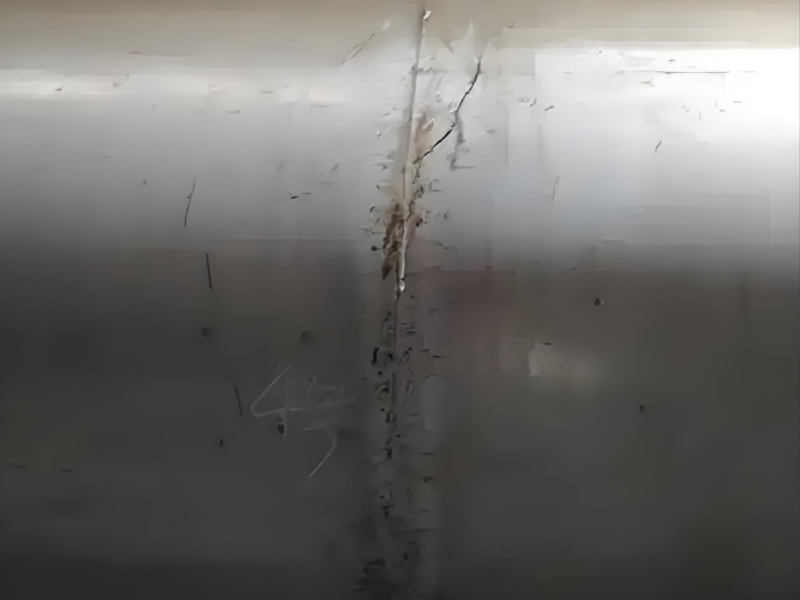

Compared with traditional manual welding, its welding performance is more stable and efficient, more convenient for industrial lean management, and its appearance is more exquisite. Its excellent welding performance has been recognized by industry insiders and is widely used in heat exchangers, condensers and other heating, ventilation and refrigeration equipment fields.

The MWH Series heat exchanger U-tube automatic welding equipment adopts advanced automatic welding equipment manufacturing technology, condensing the entire process of argon arc welding into a small hand-held welding torch. During welding, the tungsten electrode rotates around the circumferential seam of the workpiece to automatically realize welding. The whole process is self-fusing without filling wire, with button-type operation, which is convenient and fast, and the formed weld is beautiful and firm, greatly reducing the dependence on skilled workers in the welding process.

As a hand-held automatic welding equipment, its small size may inevitably arouse doubts about its welding ability, but there is no need to worry. At present, U-tube welders have mature market applications in many industries. Medium and large heat exchanger companies and Sino-foreign joint ventures generally use MeiHan equipment for welding operations.

| Product Model | Applicable Pipe Diameter |

| MWH-16A | Φ12.7mm~16.0mm |

| MWH-18A | Φ18.0mm |

| MWH-21A | Φ19.0mm~21.0mm |

| MWH-25A | Φ22.0mm~25.0 |

| MWH-12DA | Φ12.7mm |

The above U-tube welders can be customized on demand.

Since the product was launched on the market for many years, according to the feedback from customer manufacturers that have used MeiHan MWH Series heat exchanger U-tube welding equipment: the heat exchanger U-tube welding equipment customized according to the company's welding requirements has very stable welding effect, beautiful weld formation and high welding efficiency. Compared with the previous manual welding, there are fewer places that need rework, and the efficiency naturally increases. Moreover, the welders have changed from original technician-level welders to general workers, which greatly reduces labor costs and makes management easier. For U-tube welding in the heating, ventilation and refrigeration industry, MeiHan MWH Series heat exchanger U-tube welding equipment is really a good choice. With higher production efficiency and better quality, more orders will follow.

MeiHan appreciates your trust and support, and is dedicated to providing you with services!

For more products and services such as automatic pipe-pipe welders, automatic pipe-plate welders, automatic circumferential seam welding machines, and hot wire surfacing systems, please call: 18918961606 or visit Shanghai MeiHan's official website: https://www.shmeihan.com/