During the solidification process of the welding molten pool of austenitic stainless steel, there is only primary crystallization, that is, the weld metal transforms from the liquid state to the solid state. Unlike the welds of carbon steel or low - alloy steel, there is no secondary crystallization (also known as solid - state phase transformation). Therefore, for stainless - steel welds, during the process of the structure in the austenitic weld metal formed after solidification cooling to room temperature, only grain growth occurs. It should be noted that although the weld metal after solidification is continuously cooling, the temperature is still quite high, so the grain growth continues.

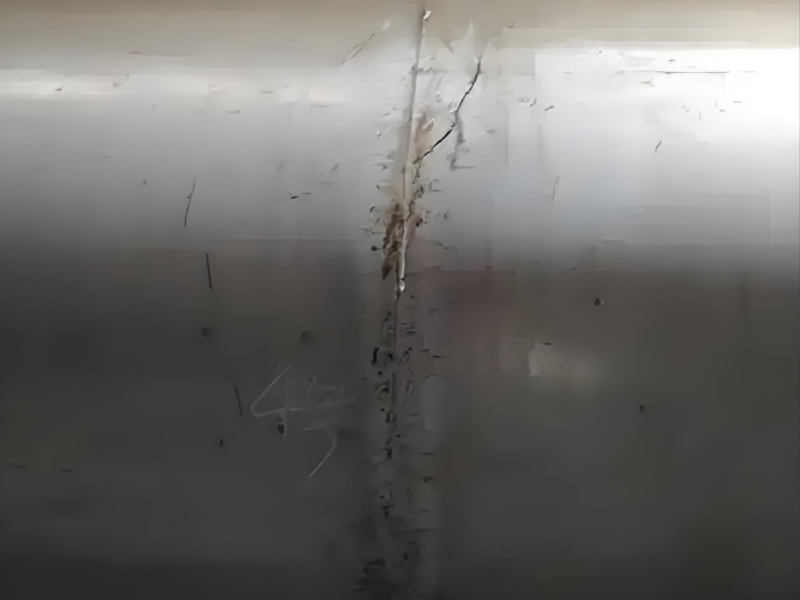

Under normal circumstances, in order to speed up the construction progress or improve production efficiency, construction parties or welders often increase the heat input to improve the deposition efficiency of welding materials. Although this seemingly improves production efficiency, in fact, there is a problem that the performance of the joint cannot be well guaranteed. This is mainly because an increase in welding heat input can lead to the burning loss of alloying elements.

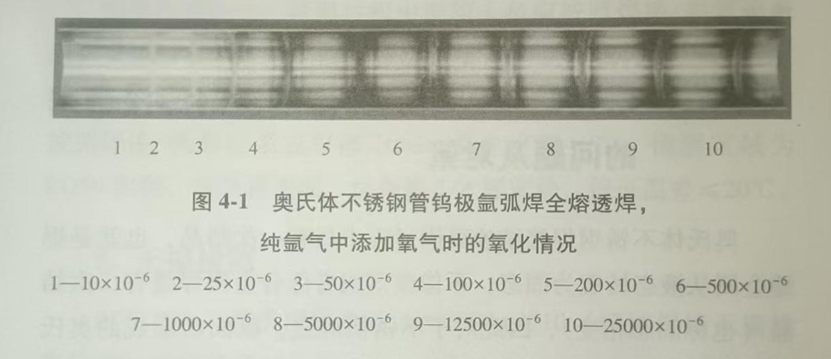

If the current is too large, resulting in excessive welding heat input, the base metal may be over - burned, and the beneficial alloying elements in the welding wire or electrode may be burned. The electrode or welding wire melts under the heat of the arc and then enters the welding molten pool. If the welding heat input is too large, the alloying elements may have been burned in the arc reaction zone. If the welding molten pool stays at a high temperature for too long, the alloying elements may be further burned during the molten - pool stage, and the solidified weld metal may also stay at a high temperature for too long and be oxidized. The oxidation situation when oxygen is added to pure argon in the full - penetration TIG welding of austenitic stainless - steel pipes is shown in Figure 4 - 1.

Problems caused by excessive welding heat input usually cannot be detected by non - destructive testing methods. This brings potential risks to the welded components or parts produced, especially to some container pipelines that store or transport high - temperature, high - pressure, and highly corrosive substances.

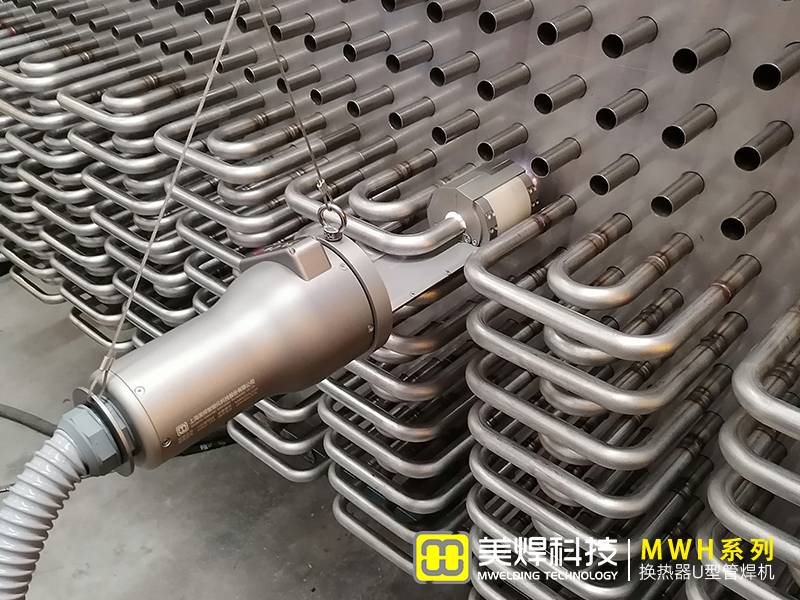

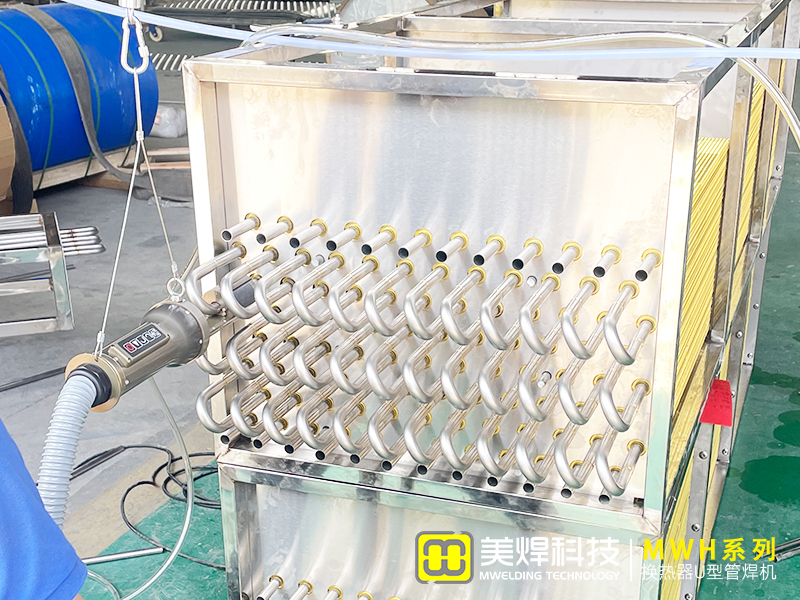

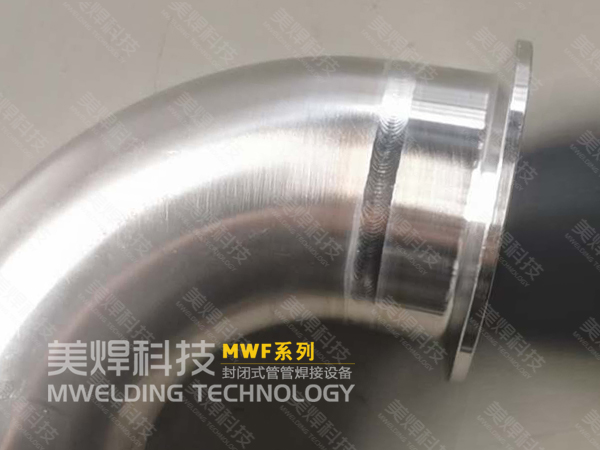

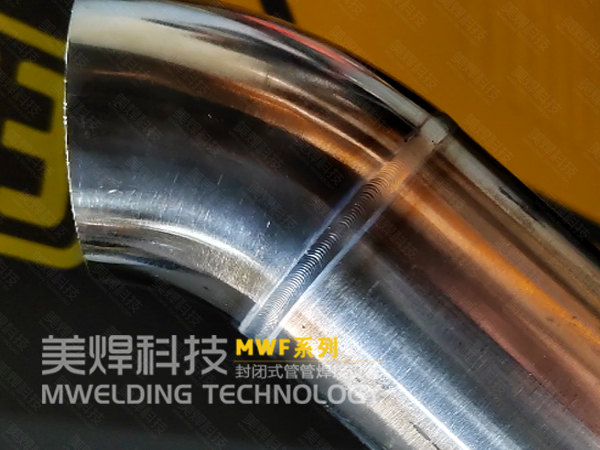

The MWF series of closed - type pipe - to - pipe welders of Meihao Welding, as professional thin - wall stainless - steel welders, are widely used in the installation of pipeline equipment in the fields of food and pharmaceutical, biological fermentation, water treatment, air - conditioning and refrigeration, and instrumentation due to their compact size and perfect one - side welding with double - side forming process. They can effectively solve the problem of excessive welding heat input.

This equipment uses core components imported from Germany. It has a lightweight structure, and is safe, precise, durable, and reliable. It is water - cooled throughout the body, and the welding gun has four - channel gas protection. It has a high duty cycle and high stability. It is suitable for the full - automatic welding of austenitic stainless - steel clean pipelines with a thickness of less than 2.5 mm and a pipe diameter of 4 - 168 mm. It is a high - performance automatic welder for clean pipelines.

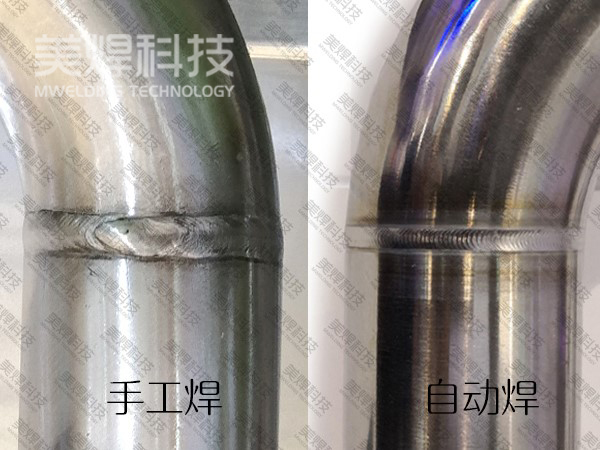

The whole welding process is digitally controlled by a computer and is equipped with an expert welding database, which enables operators to quickly get started and achieve the best welding results. At the same time, the equipment can continuously and accurately control the welding process according to different welding materials. It has good welding formation, stable output, and produces no harmful substances. It meets the hygienic - grade industry standards and the requirements for endoscopic inspection of clean pipelines. It effectively solves the problems of unstable process, low welding efficiency, and high rework rate in the traditional manual pipe - to - pipe welding process, greatly improving the welding efficiency and saving at least 30% of labor costs. It is a good helper for your precision welding and has won unanimous praise from customers after long - term market testing.

Suitable Pipe Diameters:

MWF - 12: Suitable for pipe diameters of Φ3.17 - 12.7 mm.

MWF - 40: Suitable for pipe diameters of Φ6.35 - 38.1 mm.

MWF - 80: Suitable for pipe diameters of Φ12.7 - 76.2 mm.

MWF - 120: Suitable for pipe diameters of Φ19.05 - 114.3 mm.

MWF - 168: Suitable for pipe diameters of Φ50.8 - 168.0 mm.

Welding Types:

Straight pipe - straight pipe, straight pipe - chuck, straight pipe - tee, straight pipe - elbow;

Chuck - elbow, chuck - tee, large U - bend, etc.

Customer satisfaction is our greatest support! Meihao Welding thanks you for your trust and is committed to providing you with the best service!

For more products and services such as automated pipe - to - pipe welders, automated pipe - to - plate welders, automated circumferential - seam welding machines, and hot - wire surfacing systems, please call 18918961606 or visit the official website of Shanghai Meihao Welding: https://www.mwelding.com.cn, WeChat official account, and video account for more information.