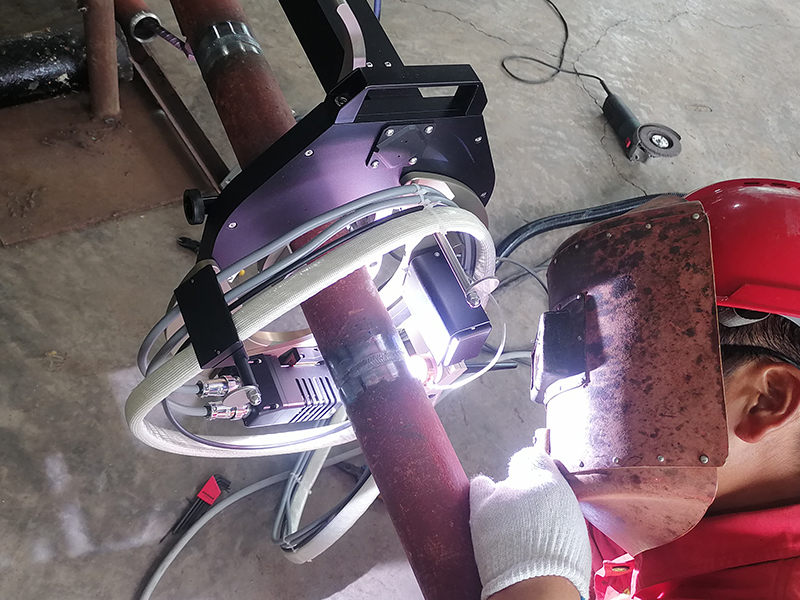

TIG welding is a common welding technique widely used in various fields such as pipeline welding and stainless steel decoration. In pipeline welding, vertical position welding of pipes is often required. Although vertical welding is challenging for beginners, high-quality welding can be achieved by mastering key techniques.

I. Preparation

Ensure thorough preparation before welding, including cleaning pipe joints, selecting appropriate welding wires and shielding gases, and checking equipment functionality.

II. Welding Techniques

Current Control: Select proper current based on pipe thickness and material. Excessive current causes burn-through, while insufficient current leads to weak welds.

Stable Arc Maintenance: Maintain a steady arc during welding through appropriate current settings and consistent travel speed.

Uniform Welding: Achieve uniform welds across the entire joint by adjusting electrode angle and travel speed.

Interpass Temperature Control: Critical for multi-layer welding. Excessive heat causes coarse grain structures and reduced mechanical properties.

III. Common Issues & Solutions

Porosity: Ensure clean joints and proper shielding gas flow to prevent porosity.

Incomplete Fusion: Adjust current and travel speed to ensure complete fusion between weld metal and base material.

Weld Cracking: Control heat input and cooling rates. Post-weld cooling may be required to reduce stress.

Mastering these techniques enables successful vertical pipe welding. Consistent practice and experience accumulation remain essential for skill improvement.

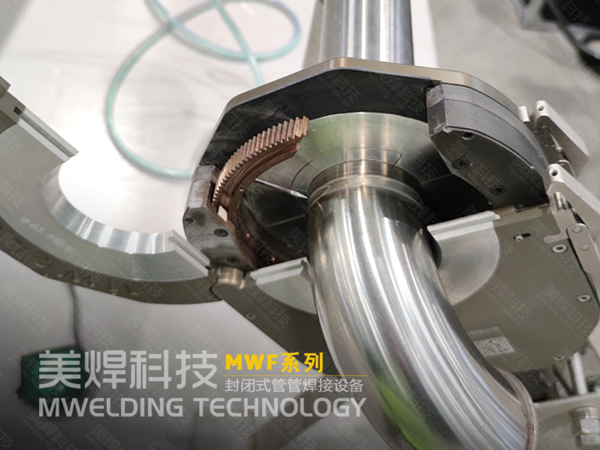

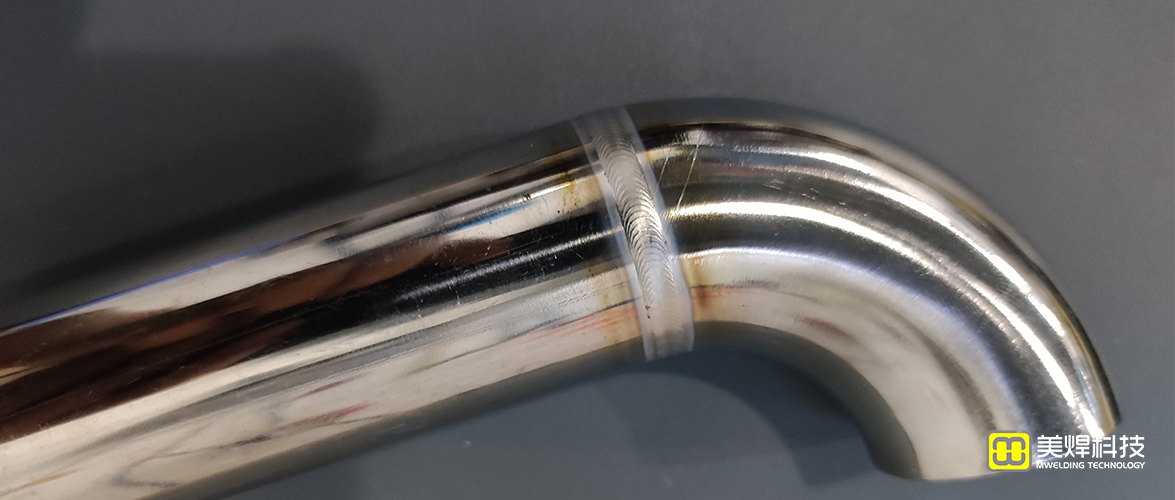

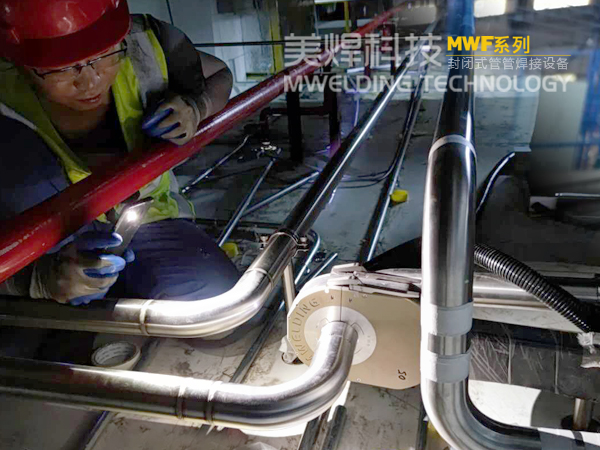

The MWF Stainless Steel Pipe Automatic Welding Machine (Tube-to-Tube Welder) works with the MWA-200 integrated control power supply to achieve full-position TIG automatic welding. It solves issues like unstable workmanship, low efficiency, and high rework rates in manual welding, improving efficiency by 30% while delivering superior weld quality.

MeiHan MWF Series Stainless Steel Tube-to-Tube Welder Technical Specifications

MWF-40: Φ6.35-38.1mm

MWF-80: Φ38.1-76.2mm

MWF-120: Φ76.2-114.3mm

Electrode Diameter: 1.6/2.4mm

Rotation Speed: 0.2-4rpm

Shielding Gas: Argon

Cooling Method: Circulating Water Cooling

Product Advantages

Fully water-cooled torch body ensures high duty cycle and extended lifespan

4-channel argon protection system improves weld aesthetics and quality

Speed feedback system ensures precise rotation control

Expert parameter settings for simplified operation and superior results

As a professional tube-to-tube welding equipment manufacturer, MeiHan provides customized solutions and full-process technical support for turnkey welding projects.