1. Pre-Welding Preparation

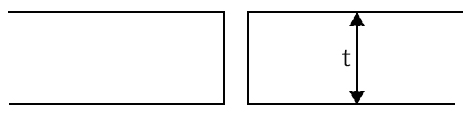

Remove impurities within 30mm on both sides of the groove and ensure the assembly gap, groove dimensions, and tack welding quality meet specifications. In humid conditions or when dew/frost exists on the groove, dry the surface before welding. Preheating shall comply with Q/DL 164-1999 standards. Submerged arc welding flux must be baked before use and used immediately after baking.

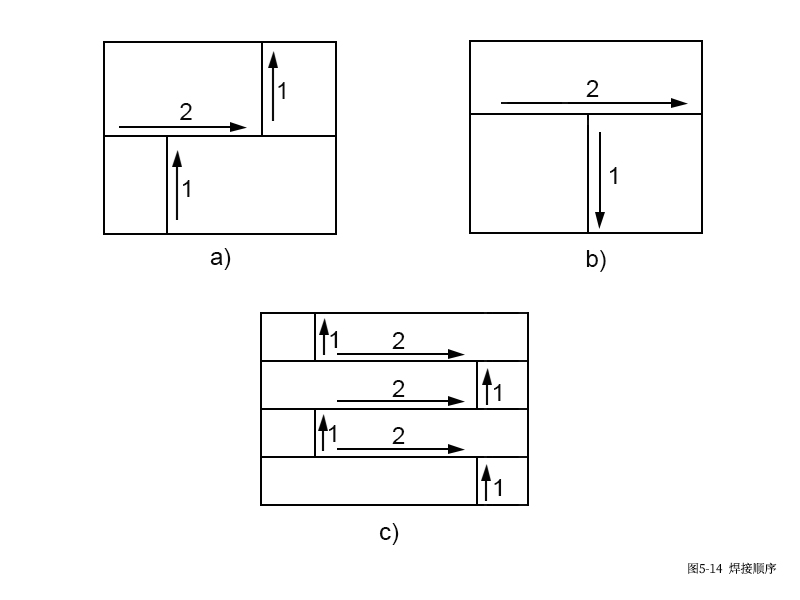

2. Welding Sequence(Welding sequence shown in Figure 5-14)

3. Welding Parameters

| Plate Thickness (mm) | Groove Type | Electrode Diameter (mm) | Welding Current (A) | Arc Voltage (V) |

| 7~13 |

| 5.0 | 850~950 | 35~39 |

| 13~36 |

| 5.0 | 650~850 | 38~42 |

4. Key Points

When the plate thickness difference exceeds 3mm, the bevel length shall be ≥4 times the thickness difference, with the bevel on the post-weld side. Assembly gap: 0~0.5mm for 6~9mm plates; 0~1mm for plates ≥10mm.

Welding run-off tabs must be installed at weld ends.

Defective welds shall be repaired using SMAW or CO₂ gas shielded welding.

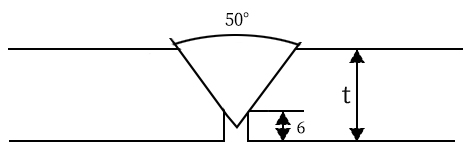

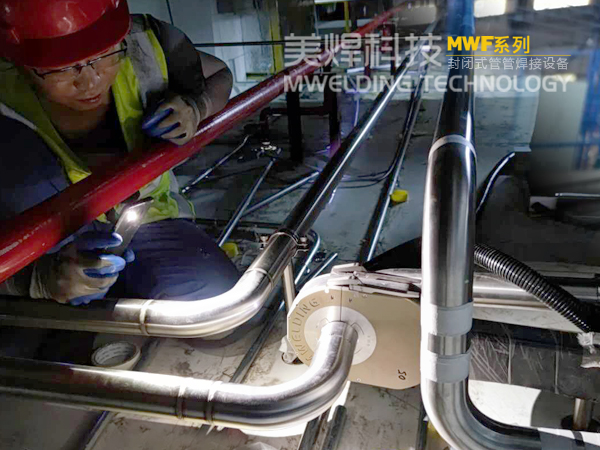

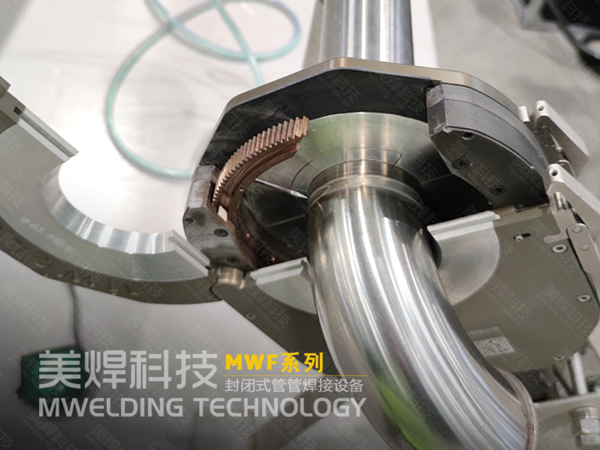

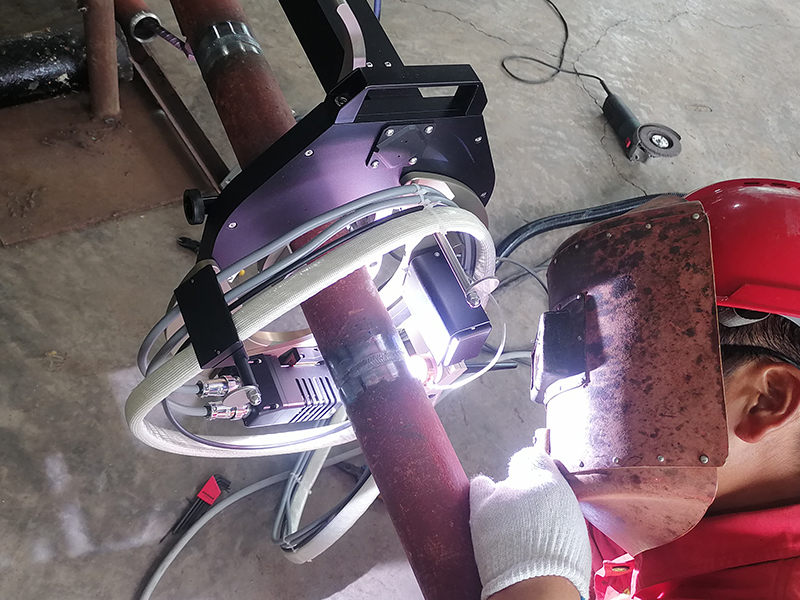

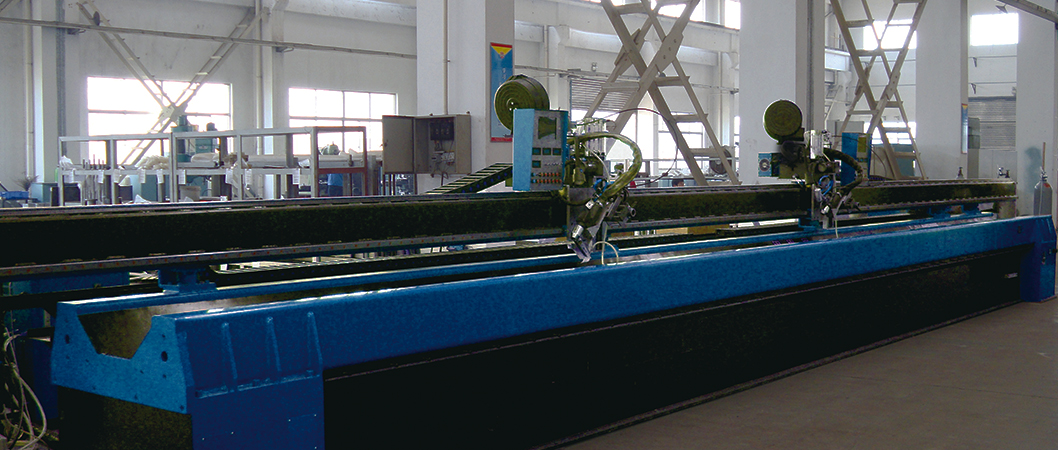

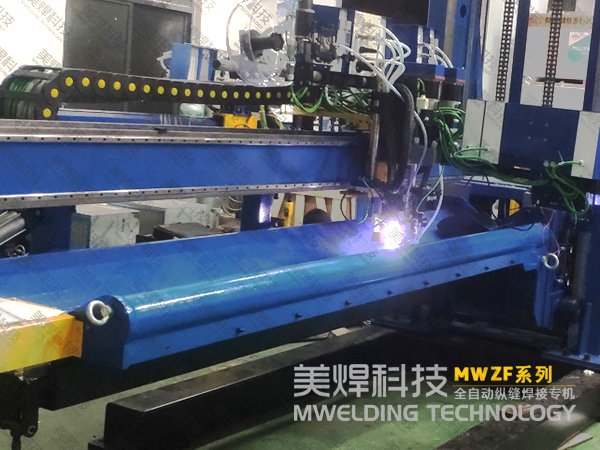

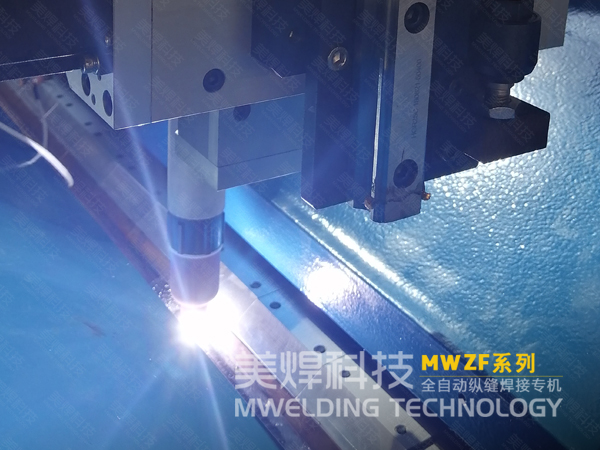

Mwelding Longitudinal Seam Automatic Welding Equipment

Mwelding longitudinal seam automatic welding equipment is widely used for straight seam welding of carbon steel, stainless steel, and titanium alloy cylinders, tanks, and plate joints. The system typically a cantilever structure with TIG/MIG/MAG torches and customized backing liners/grooves to achieve one-side welding with double-sided formation.

Product Features

Applicable Range:

Pipe diameter: 300mm–5000mm; Plate thickness: 0.5–12mm

Welding types: Plate splicing, straight seam welding

Power supply options: Fronius (Austria), EWM (Germany), Panasonic (Japan)

Control system options: Siemens (Germany), Mitsubishi (Japan), Xinjie (China)

Advantages of MWZF Series

Imported welding power supply + customized fixtures ensure stable performance.

Multiple control signal outputs for flexible process integration.

Water-cooling system enables continuous operation.

Enhanced gas shielding for optimal weld pool protection.

Modular design for quick disassembly/maintenance.

High anti-interference, reliability, and speed stability.

The equipment features a stainless steel frame for load-bearing capacity, compact design for easy installation, and imported motors/software for precision control.

Contact Us:

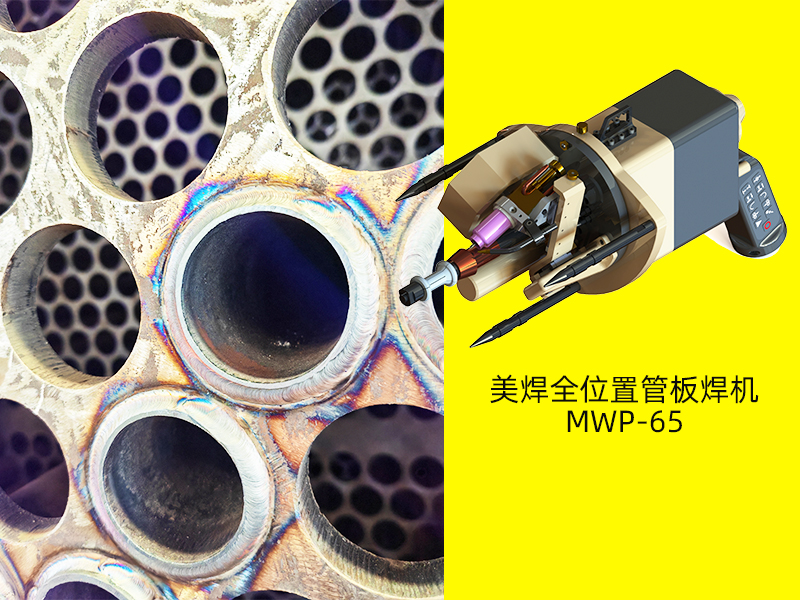

For more automated welding solutions (tube-to-tube, tube-to-plate, circumferential seam welding, hot wire cladding, plasma welding), visit https://www.mwelding.com.cn or call +86 189 1896 1606.