1. Problem Description

When welding two materials with a large difference in melting points, a type of crack is likely to occur, which can be classified as a hot crack. The initiation of this hot crack originates from the interface between the high-melting-point metal and the low-melting-point metal. The low-melting-point metal diffuses along the grain boundaries of the high-melting-point metal or penetrates into the weld or base metal of the high-melting-point metal. Under the action of stress, cracking occurs along the grain boundaries of the high-melting-point metal.

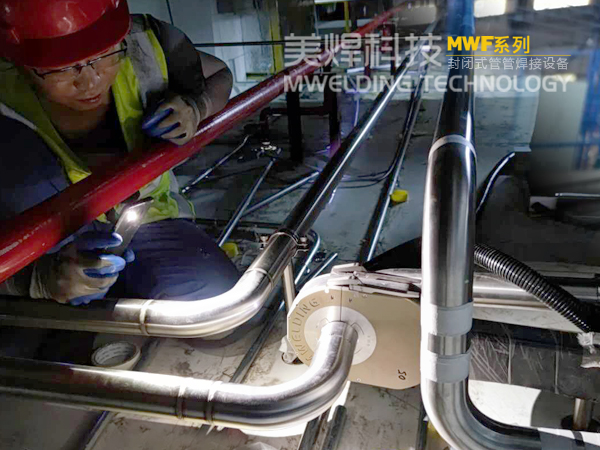

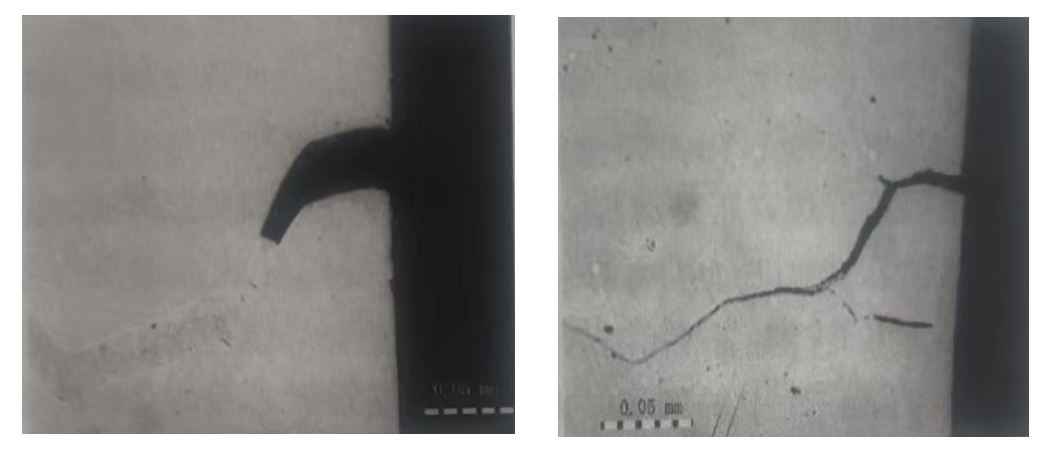

For example, when brazing a stainless-steel tube and a copper tube, phosphor-copper filler metal is used for flame brazing. To improve the wettability of the surface of the stainless-steel tube, a copper film is first coated on the wall of the stainless-steel tube, and then flame brazing is carried out. After welding, cracks are found on the stainless-steel tube side during penetrant testing, as shown in the figure.

Cracks are found on the stainless-steel tube side during penetrant testing after welding.

2. Problem Analysis

After dissecting the tube joint and preparing a metallographic specimen, it is found that the crack initiates from the inner wall of the stainless-steel tube and propagates along the grain boundaries to form a crack. There is a copper film distributed on the grain boundaries, as shown in Figure 1-26. It is speculated that the molten copper filler metal diffuses and penetrates along the grain boundaries of the stainless-steel grains during the brazing process and cracks under the welding thermal stress.

Figure 1-26 Intergranular crack that initiates and propagates from the inner wall of the stainless-steel tube.

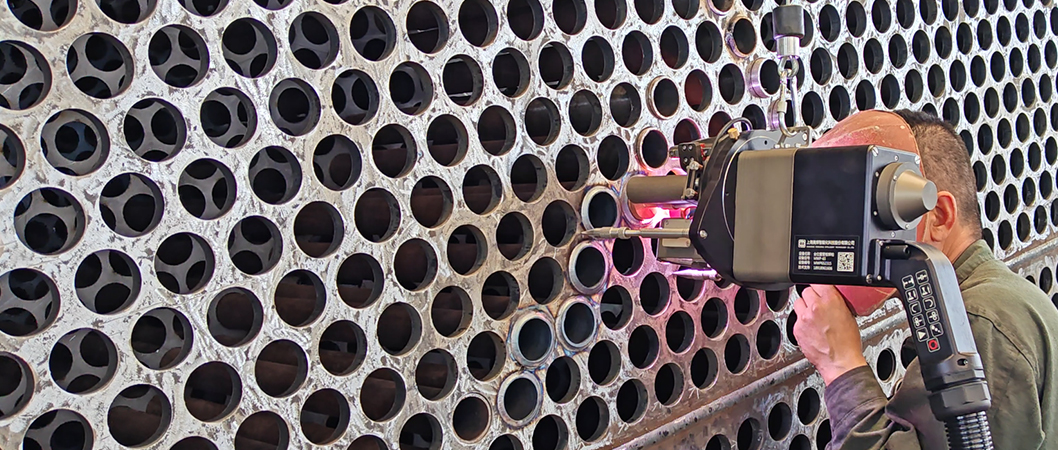

There is a copper film on the grain boundaries. This phenomenon not only occurs in the joints of stainless-steel tubes and copper tubes brazed with phosphor-copper filler metal but also in the joints of other materials. For example, in a fixed tube-sheet heat exchanger, the heat exchanger tube is made of 904L (this material itself contains 1.4% copper by mass fraction), and the tube sheet is made of Q355. 904L with a thickness of 12 mm is surfacing welded on Q355. The fillet weld between the heat exchanger tube and the tube sheet is welded by semi-automatic tungsten inert gas arc welding. After the second layer of welding, cracks appear at the ends of some heat exchanger tubes. The fillet weld between the heat exchanger tube and the tube sheet is shown in Figure 1-27. After dissecting the joint with cracks, a copper film is found on the crack fracture surface, and the copper content in this area is about 77% (mass fraction).

3. Solutions

Whether it is brazing or fusion welding, the heating temperature should be strictly controlled during welding, and the residence time at the high-temperature stage should not be too long, so that this type of crack can be effectively avoided.

For the example in the figure, due to the large stress concentration at the fillet weld between the heat exchanger tube and the tube sheet, and the mutual influence of heating and cooling of the surrounding fillet welds of the tube sheet during welding, the stress is relatively large. In this case, the on-site measures taken are to reduce the leg length of the fillet weld, try to complete the welding in one pass (weld flat without wire filling in the first circle, and form a fillet weld with wire filling in the second circle, avoiding the third circle of welding or repair welding at some positions), use a small welding heat input, and reasonably design the welding sequence, etc.

4. The Most Important Part

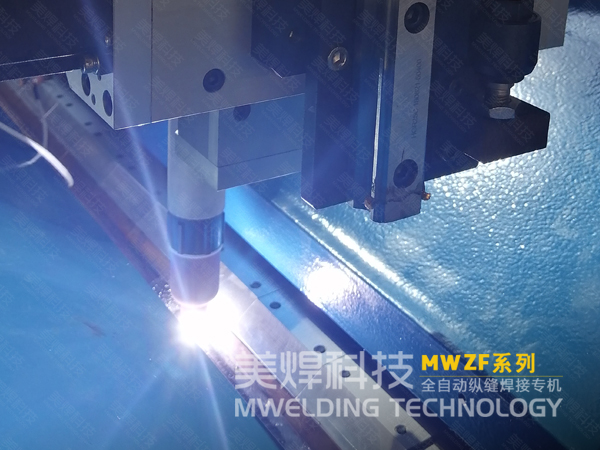

From the appearance, good welding quality means that the weld appearance should be flat and beautiful, free of cracks, slag inclusions, pores, and other defects, and meet relevant standards and drawing requirements. The mechanical properties of the welded joint are evaluated through tensile, bending, impact, and other tests to ensure that it meets the strength and toughness indicators required by the design. When necessary, non-destructive testing methods such as radiography and ultrasonic testing are used to detect the internal quality of the weld to ensure that there are no cracks, lack of fusion, and other defects inside the weld. For welded parts in some specific application scenarios, corrosion resistance tests are also required to evaluate their corrosion resistance in specific environments.

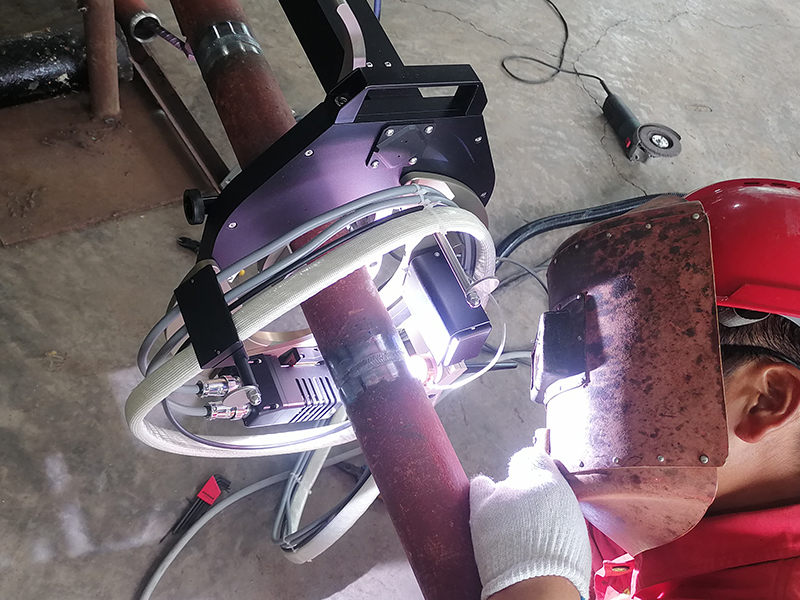

As an efficient and precise welding equipment, the digital TIG tube-to-tube sheet automatic welding machine is widely used in industries such as energy, boilers, and ships. Its emergence not only improves production efficiency but also ensures welding quality, reduces the risks and labor intensity of manual operations, and plays an important role in promoting the development of these industries. In practical applications, according to specific process requirements and working conditions, the tube-to-tube sheet automatic welding machine can be reasonably selected and configured, and combined with strict quality control and inspection, it can provide strong support for the development of the energy, boiler, and ship industries.

Compared with traditional welding methods, the digital tube-to-tube sheet automatic welding machine has the following advantages:

High welding efficiency: The digital tube-to-tube sheet automatic welding machine adopts an automated welding method, which can quickly, simply, and accurately complete batch welding tasks, greatly improving welding efficiency. At the same time, the welding equipment can achieve continuous welding for a long time. Combined with effective personnel arrangements, the product delivery efficiency can be effectively improved.

Stable welding quality: The digital tube-to-tube sheet automatic welding machine adopts advanced control systems and welding processes, which can effectively reduce the impact of human factors on welding quality and ensure the stability and uniform forming of welding quality.

Reduced labor costs: The digital tube-to-tube sheet automatic welding machine has a high degree of automation, which can greatly reduce the requirements for manual welding operations, thereby reducing labor production costs.

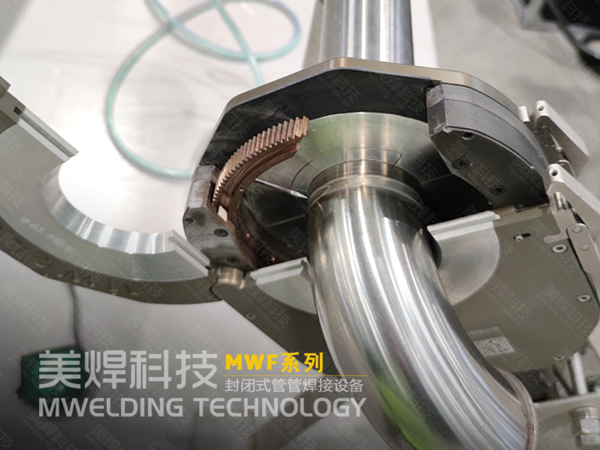

Good functionality and adaptability: The digital tube-to-tube sheet automatic welding machine is suitable for tube-to-tube sheet welding of various materials, thicknesses, and multiple processes. Whether it is carbon steel, stainless steel, or titanium alloy materials, it can easily handle them.

Environmental protection and energy saving: The digital tube-to-tube sheet automatic welding machine can effectively reduce the emission of waste gas and waste residue during the welding process and reduce energy consumption, which has the advantages of environmental protection and energy saving.

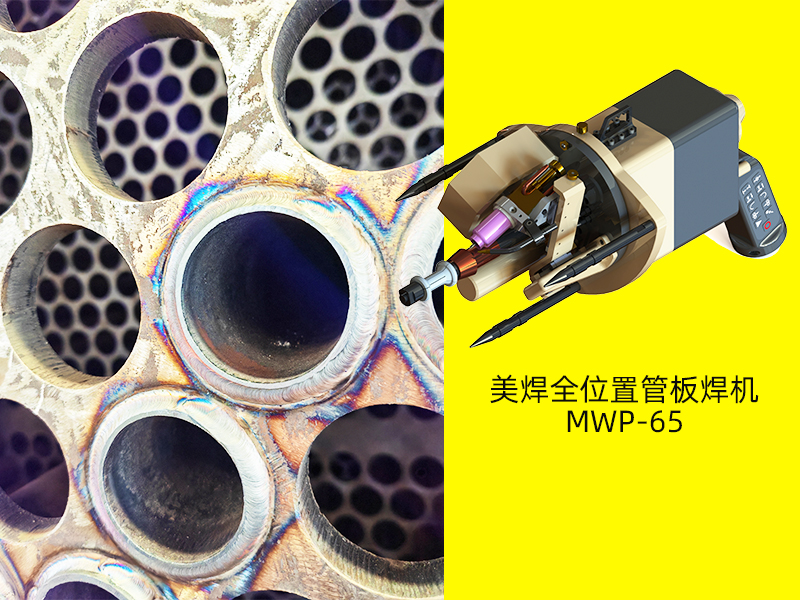

Mwelding has been engaged in the research and development, production, and manufacturing of arc welding equipment for decades, and its products are widely used in the market. The MWP series all-position tube sheet welding machine originates from German production standards, uses imported core components and raw materials, has stable performance, high cost performance, and a low failure rate. The fully automatic digital intelligent welding control system has an automatic arc length adjustment function, which can meet the welding of different pipe fittings, reduce human interference, and is easy to operate. On the premise of ensuring excellent and stable internal and external welding quality of products, it greatly reduces the requirements for manual welding skills and reduces production costs. It is a safe, reliable, economical, and portable high-performance tube sheet welding machine.

The complete set of equipment supports industry customization to give you a perfect welding experience. Customer satisfaction is our greatest support! Mwelding thanks you for your trust and support and is committed to providing you with services!

For more products and services such as automated tube-to-tube welding machines, automated tube-to-tube sheet welding machines, automated circumferential seam welding special machines, and hot wire surfacing systems, please call: 18918961606 or visit the official website of "Shanghai Mwelding": https://www.mwelding.com.cn, WeChat official account, and video account.