1. Problem Description

For the welding of piping systems and the butt joints of non-ferrous metals and carbon steel plates with relatively large thicknesses, backing welding is usually required. The welding processes for backing welding are argon arc welding and CO₂ gas shielded welding. During the welding construction, some welders use extremely high currents for backing welding in order to speed up the progress. Whether using argon arc welding, shielded metal arc welding, or CO₂ gas shielded welding for backing welding, cracks along the weld direction in the center of the backing weld are often found during the construction process. The essence of these cracks is hot cracks.

2. Problem Analysis

Compared with argon arc welding, the welding heat input is larger and the cooling speed of the weld is slower when using shielded metal arc welding and CO₂ gas shielded welding for backing welding. On the one hand, when the heat input during the welding process is large, the restraint stress of the base metal around the weld on the weld is very large, which easily leads to defects such as overburning and undercutting, and also easily causes the grains in the heat-affected zone to become coarse, resulting in a hard structure and reduced toughness. If the welding heat input is too small, defects such as incomplete penetration are likely to occur. On the other hand, since it is the first weld pass and the temperature of the base metal is very low, the heating and cooling speeds of the backing welding are fast, and the resulting thermal stress due to thermal expansion and contraction is quite large. If the solidification speed of the welding pool of the backing welding is slow, it will be pulled apart by the restraint stress and thermal stress of the base metal. Since the center of the weld has not completely solidified at this time, solidification cracks, that is, hot cracks, are formed. Such cracks may appear in the girth welds of ships and pipelines. If cellulose electrodes are directly used for backing welding, the weld will crack immediately after solidification in places with relatively large stress.

3. Countermeasures

When performing backing welding (sometimes special backing welding consumables are also required), a small specification and appropriate welding heat input should be selected. Everyone knows that backing welding is very important and is the first step to ensure the smooth progress of subsequent welding. When performing backing welding, first of all, it is required to ensure that the thickness of the backing weld layer is about 3 mm, so that cracks will not occur under stress conditions; secondly, there should be no welding defects, and these defects mainly include pores, slag inclusions, cracks, and lack of fusion, etc.; thirdly, if the area around the welding groove of the first weld pass of the backing welding is not cleaned thoroughly, it is easy to contaminate the weld. For example, moisture, rust, and oil stains can easily add hydrogen to the weld and even leave hidden dangers for inducing hydrogen-induced cracks.

Generally speaking, compared with shielded metal arc welding and CO₂ gas shielded welding, the cleanliness of the weld bead of argon arc welding for backing welding is higher. Under the same conditions, the weld metal of the latter two has better resistance to hydrogen-induced crack sensitivity. Because the heat input of argon arc welding is small and the cooling speed is fast, it will not be pulled apart under the action of the restraint stress and thermal stress of the base metal. Of course, if the current of argon arc welding is relatively large and the welding speed is slow, cracks will also appear in the weld bead.

If a relatively large heat input is adopted, regardless of the welding method used, it will have an impact on the cooling speed after welding and thus have an impact on the microstructure and properties of the weld heat-affected zone. When other parameters are the same, a larger welding heat input will result in a slower cooling rate after welding, affecting indicators such as the strength, crack resistance, toughness, and plasticity of the weld. Therefore, a small heat input should be adopted for backing welding to ensure the welding quality.

After similar cracks appeared in the backing weld at a certain factory's welding construction site, after changing to argon arc welding for backing welding or adopting a welding method with a small heat input, similar cracks never appeared again.

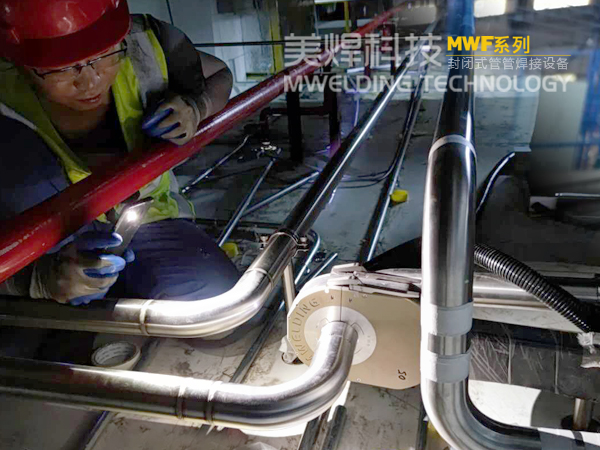

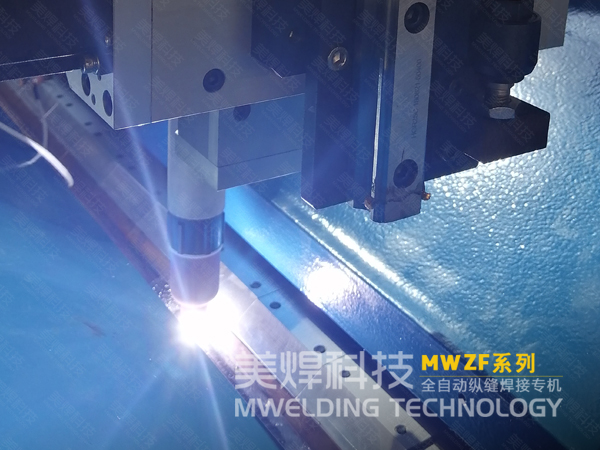

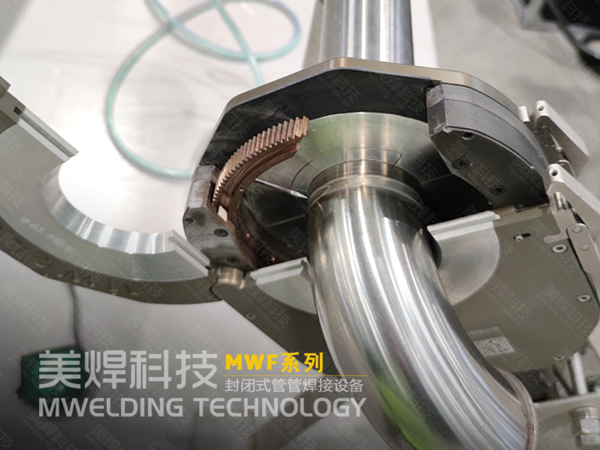

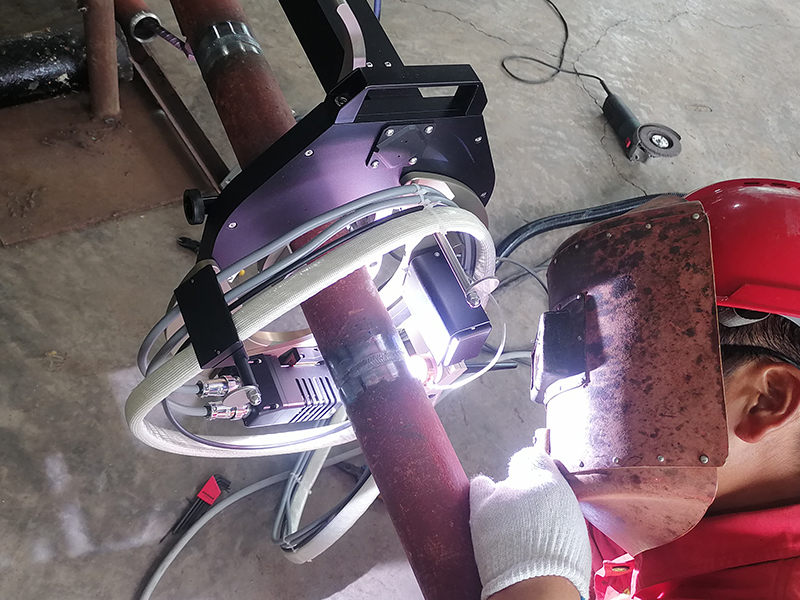

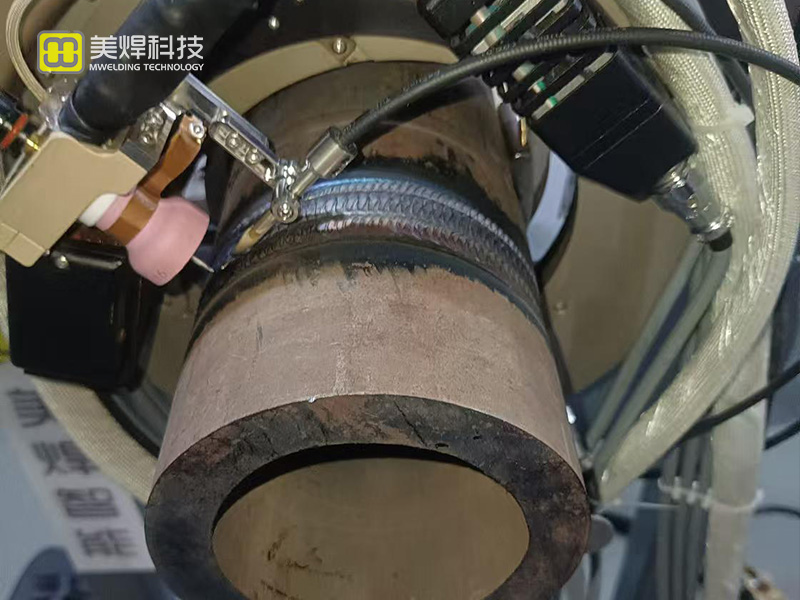

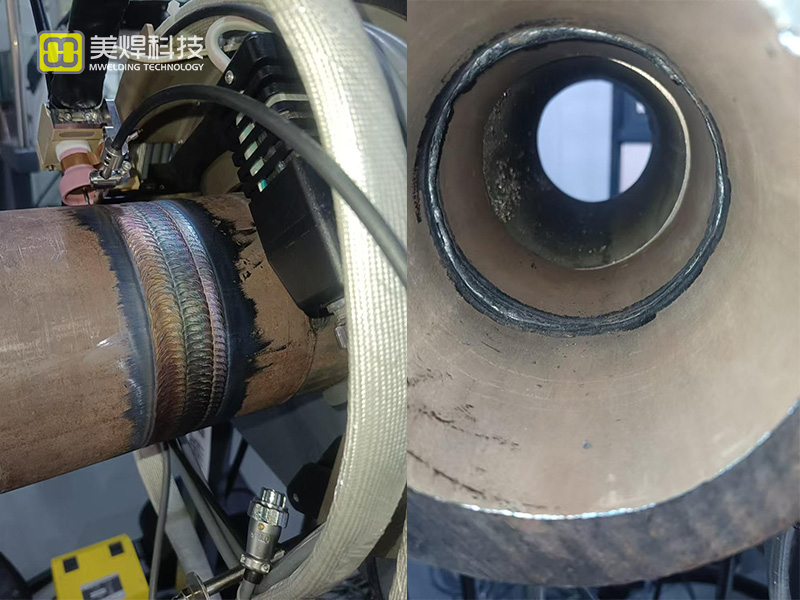

The MWG pipeline automatic welding machine, with the help of a 360-degree rotating welding clamp and equipped with an automatic welding intelligent control system, can well realize the automatic circumferential argon arc welding operations of backing, filling, and capping for petroleum and chemical pipelines without moving the pipe fittings. On the premise of confirming the process parameters, the stable output of high-quality welds ensures the uniformity and reliability of pipeline welding.

Relying on the intelligent digital welding control system, the MWG pipeline automatic welding machine can well realize the precise and stable control of the automatic welding process parameters of pipelines. After the process technicians debug the welding parameters according to the welding situation of the pipes and store them, it is no longer difficult to achieve high-quality, uniform, and stable welding output. At the same time, with the support of the digital information data storage and printing management functions, the control and optimization of welding quality become conducive to traceability analysis and continuous improvement.

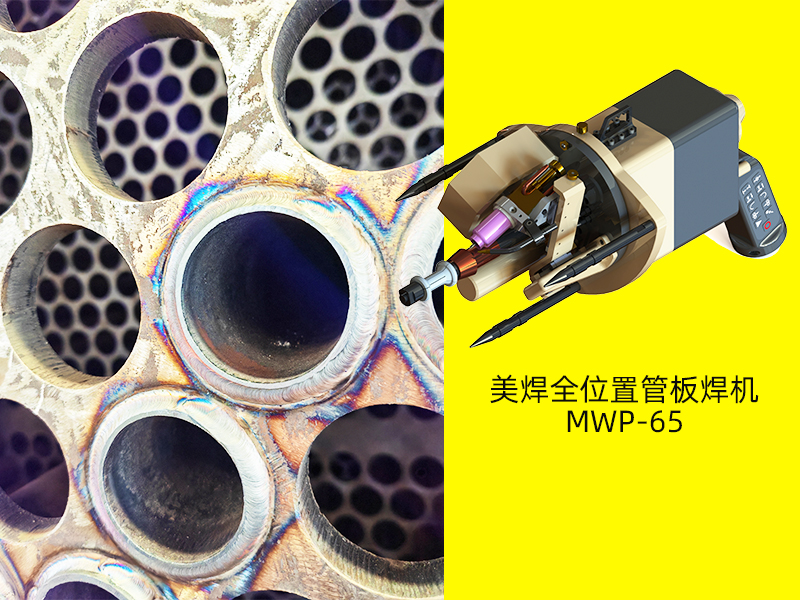

The MWG series pipeline automatic welding machines of Mwelding are committed to demonstrating their superior performance and price. With patented technologies and German component processes, they have been on the market for decades and are widely used in fields such as energy and power, boilers and chemical engineering, petroleum pipelines, pressure vessels, and pipeline installation. The whole machine adopts a modular design, which is ingeniously designed and compact in structure. The scientifically and reasonably designed infinitely adjustable caliper-type fixtures fully meet the clamping requirements of pipe diameters within the equipment's coverage range and effectively ensure the coaxial operation of the pipe and the welding trajectory. It has the functions of automatic arc length and oscillation control and can realize single-sided welding and double-sided forming of tungsten inert gas arc welding for backing welding, meeting the requirements of a grade II weld qualification rate of more than 98% for radiographic inspection or ultrasonic inspection. It also meets the requirements of pressure-bearing tests or physical property tests such as impact, tensile, and bending.

1. Application industries: Pressure vessels, boilers, chemical and petroleum pipeline installation, etc.

2. Applicable scope: Welding of materials such as stainless steel, carbon steel, and titanium alloy.

3. Applicable pipe diameters:

MWG-48 is suitable for pipe diameters: Φ19 - 38 mm, wall thickness ≤ 6 mm;

MWG-90 is suitable for pipe diameters: Φ20 - 89 mm, wall thickness 1 - 10 mm;

MWG-170 is suitable for pipe diameters: Φ63 - 168 mm, wall thickness 2 - 10 mm;

MWG-230 is suitable for pipe diameters: Φ130 - 230 mm, wall thickness 2 - 10 mm;

MWG-325 is suitable for pipe diameters: Φ159 - 325 mm, wall thickness 2 - 10 mm.

Mwelding thanks you for your trust and support and is wholeheartedly committed to providing you with services!

For more products and services such as automatic tube-to-tube welding machines, automatic tube-to-plate welding machines, automatic girth welding special machines, and hot wire surfacing systems, please call: 18918961606 or visit the official website of Shanghai Mwelding: https://www.mwelding.com.cn

This article is cited from "Analysis and Countermeasures of On-site Welding Problems" by Xue Xiaohuai and Yang Wenhua, published by China Machine Press.