Analysis of Welding Difficulties of High-Pressure Mud Pipes and Countermeasures, and Recommendation of an Intelligent and Automated Welding Marvel for High-Pressure Mud Pipes

Problem Description

High-pressure mud pipes are an important part of the drilling fluid circulation system. Due to the strong corrosiveness of high-pressure mud and the extremely high working pressure during transportation, high requirements are put forward for the material, welding quality, fabrication and inspection of high-pressure mud pipes.

Problem Analysis

(1) Technical requirements of the American Society of Corrosion Engineers Standard NACE MR 0175 for high-pressure mud pipes

The material grade of high-pressure mud pipes: AS19CR4130 (chromium-molybdenum series low-alloy steel). The technical agreement comes from the "Requirements for Metallic Materials for Resistance to Sulfide Stress Corrosion Cracking (SCC) in Piping and Equipment in Service Containing H₂S and in Processing Equipment" in the NACE MR 0175 standard. Damage caused by SCC will lead to the inability of equipment to return to the working state when continuing to bear pressure, endangering the integrity of pressure-bearing equipment or making the equipment unable to perform its basic functions.

When using chromium-molybdenum series low-alloy steel to manufacture pipes and pipe components, if cold straightening is carried out at a temperature lower than 510 °C, stress relief heat treatment at a temperature not lower than 480 °C must be carried out; if cold forming is performed, stress relief heat treatment at a temperature not lower than 595 °C must be implemented in the cold-worked area. For the connections of high-strength pipes with a hardness greater than 22 HRC after cold working, stress relief heat treatment at a temperature not lower than 595 °C must be carried out. Meanwhile, when using these alloy steels and the hardness of the pipe after cold working is greater than 22 HRC, it is customary to conduct a hydrogen sulfide embrittlement crack test to determine the material's resistance to SCC performance.

(2) Difficulties in the manufacturing process of high-pressure mud pipes

It can be seen from the technical requirements that the construction difficulty of high-pressure mud pipes lies in controlling the heat treatment process to ensure that the hardness of the weld, heat-affected zone and weld end face is not greater than 22 HRC.

Countermeasures

(1) Welding process of high-pressure mud pipes

Since there is no detailed material grouping for GR4130 material in ASME, the welding procedure qualification adopts the ASME IX specification and also needs to meet the requirements of the NACE MR 0175 standard and the technical agreement of high-pressure mud pipes. High-pressure mud pipes have high working pressure and high requirements for the quality of welded joints. Therefore, pipes with a specification of Φ141.3mm×19.5mm are selected, and the main coverage meets the requirements of this welding process.

(2) Welding position and groove form

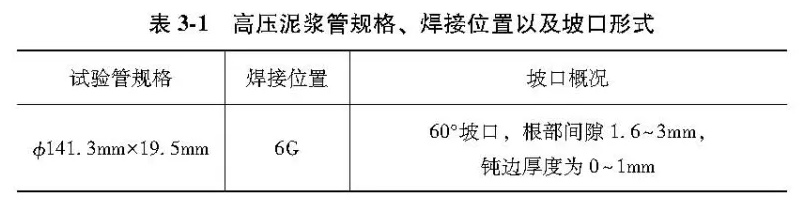

The specifications, welding positions and groove forms of high-pressure mud pipes are shown in Table 3-1.

Note: 6G - Welding with the pipe inclined at 45°.

(3) Selection of welding materials

The selection of welding materials should meet the requirements of the mechanical properties of the base metal and also meet the requirement in the NACE MR 0175 standard that the N content of welding materials is not greater than 1% (mass fraction). Meanwhile, the higher the strength of welding materials, the higher the hardness of the weld will be. Therefore, welding materials of grades ER100S-G and E10018-D2 (American standard) are selected.

(4) Determination of preheating and interpass temperatures

According to the carbon equivalent calculation formulas recommended by the International Institute of Welding (IIW) and the American Welding Society (AWS), the calculated carbon equivalent is 0.52% - 0.77%. It can be seen that the weldability of GR4130 is poor. According to the preheating temperature recommended by ASME, which is 130 °C, considering that the purpose of preheating is to reduce the cooling rate of weld metal and avoid the occurrence of cold cracks, the preheating temperature is set at 150 - 160 °C according to the actual situation to ensure an appropriate cooling rate and ensure that no cold cracks appear in the weld metal and heat-affected zone. The temperature measurement points are within the range of 50 - 75 mm on both sides of the groove.

(5) Post-weld heat treatment plan

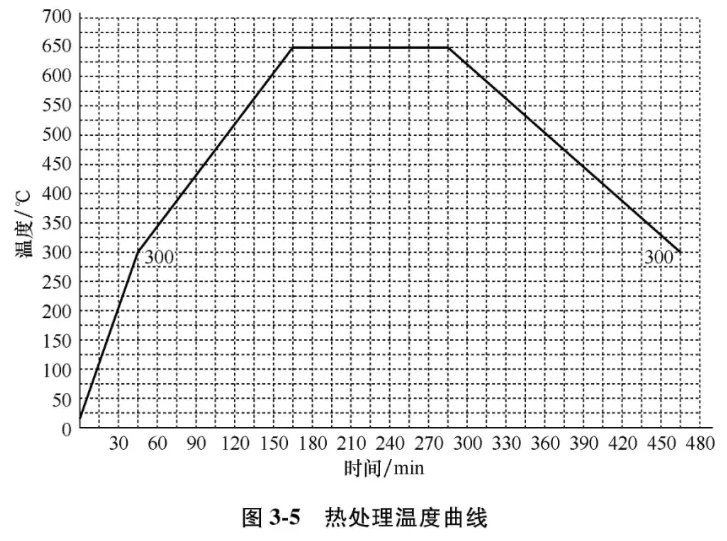

The main role of post-weld heat treatment is to relieve stress. However, it should be noted that an overly high heat treatment temperature will reduce the toughness and strength of the weld. According to the requirements of the NACE MR 0175 standard, in order to achieve a hardness not greater than 22 HRC, heat treatment at a temperature not lower than 595 °C is required. Combining the requirements of ASME and AWS for the heat treatment temperature and holding time (1h/25mm) of different strength low-alloy steels, and integrating the recommended heat treatment process specification parameters of the above three standards, the final post-weld heat treatment process parameters are determined as follows: the heat treatment temperature is 650 °C, and the holding time is 2h. The heat treatment temperature curve is shown in Figure 3-5.

The critical temperature for heat treatment is set at 300 °C. The heating rate from 300 °C to 650 °C is set at 180 °C/h, and the cooling rate from 650 °C to 300 °C is 150 °C/h. The hardness of the welding heat-affected zone (HAZ) is the key point in hardness control. In the hardness test, it should be noted to use the NACE standard. The average value of three adjacent points is 22 HRC. If one point exceeds this value but the excess is not greater than 2 HRC, it meets the requirements.

Analysis of the V-notch impact toughness of welds

The selection of welding materials should meet the requirement of -40 °C impact toughness. The impact toughness test temperatures for the welds of high-pressure mud pipes are set at -40 °C and 0 °C, and both schemes are carried out simultaneously, which can not only meet the technical requirements but also make technical preparations for subsequent product production. The -40 °C low-temperature impact test has high requirements for the welding process. It is necessary to start with the selection of welding materials and the welding process, mainly controlling the welding heat input and interpass temperature, and adopting multi-layer and multi-pass welding. Strictly control the forming coefficient of each weld, record the number of welding layers and the number of passes in each layer, and adopt slow cooling process measures for the weld during the whole process of welding and after welding to ensure that the low-temperature impact toughness data of the weld meet the standards and technical requirements, especially the impact toughness value in the center of the weld.

Further Analysis

Through the research on the process, manufacturing and installation of high-pressure mud pipes on drilling barges, from the perspective of the process, the process test is mainly to study the mechanical properties and macroscopic properties of welded joints. This welding process example is more conducive to the control of weld quality: adopting multi-layer and multi-pass welding, controlling the thickness of the weld layer, and the latter weld pass has a tempering effect on the former weld pass; using ultra-low hydrogen electrodes, not swinging horizontally, and controlling the arc length well, so that air is not easy to enter the molten pool and the porosity sensitivity of the weld is reduced; each weld pass uses grinding to remove slag and treat the weld surface, and the probability of slag inclusion in the weld will be very small. The internal quality control of the welds of high-pressure mud pipes is controlled and verified through non-destructive testing. A large number of actual welding site work shows that the outer surface of the pipe base metal may have excessive hardness, so it is necessary to test the hardness of the base metal during the test. Therefore, it is necessary to standardize the processes such as pipe straightening, welding, heat treatment and handling to prevent the hardness from increasing after heat treatment.

Recommendation of an Intelligent and Automated Welding Marvel for High-Pressure Mud Pipes

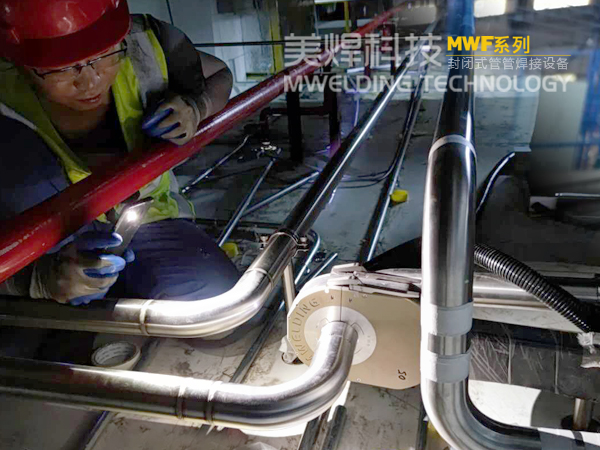

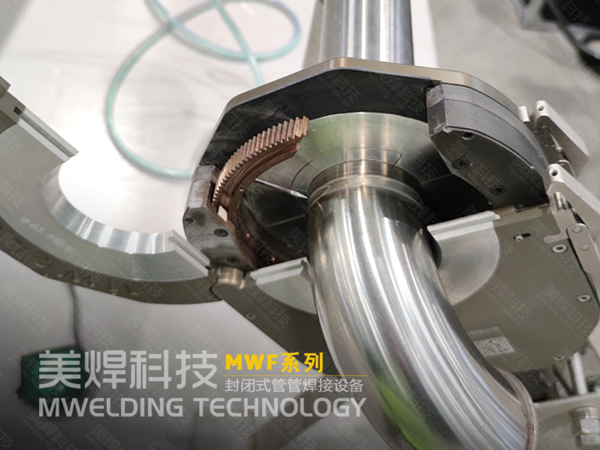

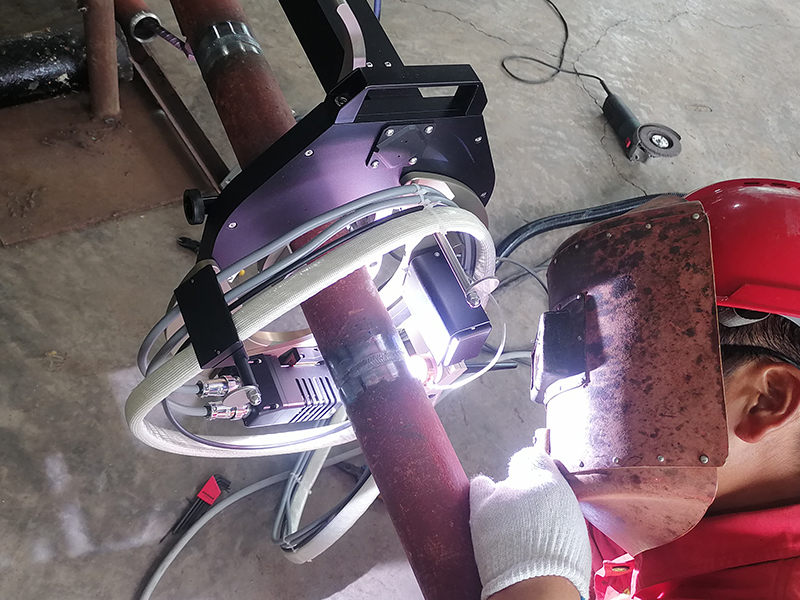

The MWG automatic pipe welding machine, with the help of a 360-degree rotating welding clamp and equipped with an automated welding intelligent control system, can well realize the argon arc welding operations of root pass, filling and capping for petrochemical pipes automatically while the pipe fittings remain stationary. On the premise of confirming the process parameters, the stable output of high-quality welds ensures the uniformity and reliability of pipe welding.

Relying on the intelligent digital welding control system, the MWG automatic pipe welding machine can well realize the precise and stable control of the automatic welding process parameters of pipes. After the process technicians adjust and store the welding parameters according to the welding situation of the pipes, it is no longer difficult to achieve high-quality, uniform and stable welding output. Meanwhile, with the support of the digital information data storage and printing management function, the control and optimization of welding quality become conducive to traceability analysis and continuous improvement.

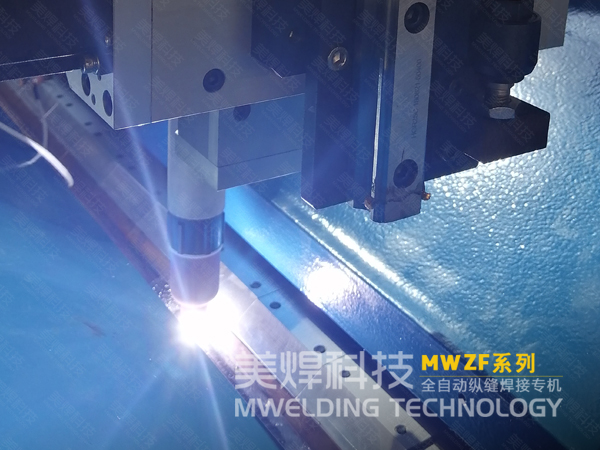

The Mwelding MWG series automatic pipe welding machines are committed to demonstrating excellent performance and reasonable prices. With patented technologies and German component processes, they have been on the market for decades and are widely used in fields such as energy and power, boiler chemical industry, petroleum pipelines, pressure vessels, and pipeline installation. The whole machine adopts a modular design, which is ingeniously designed and compact in structure. The scientific and reasonable infinitely adjustable caliper-type fixture fully meets the clamping requirements of pipe diameters within the equipment coverage range and effectively ensures the coaxial operation of the pipe and the welding trajectory. It has the functions of automatic arc length and transverse swing control. It can realize single-sided welding and double-sided forming of tungsten inert gas arc welding for root pass welding, meeting the requirements of a 98% or higher qualification rate for grade II welds in radiographic testing or ultrasonic testing. It also meets the requirements of pressure-bearing tests or physical property tests such as impact, tensile and bending.

Application industries: Pressure vessels, boilers, chemical petroleum pipeline installation, etc.

Applicable scope: Welding of materials such as stainless steel, carbon steel, and titanium alloy.

Applicable pipe diameters:

MWG-90 is suitable for pipe diameters: Φ20 - 89mm, wall thickness 1 - 10mm;

MWG-170 is suitable for pipe diameters: Φ63 - 168mm, wall thickness 2 - 10mm;

MWG-230 is suitable for pipe diameters: Φ130 - 230mm, wall thickness 2 - 10mm;

MWG-325 is suitable for pipe diameters: Φ159 - 325mm, wall thickness 2 - 10mm;

Mwelding thanks you for your trust and support and will wholeheartedly provide you with services!

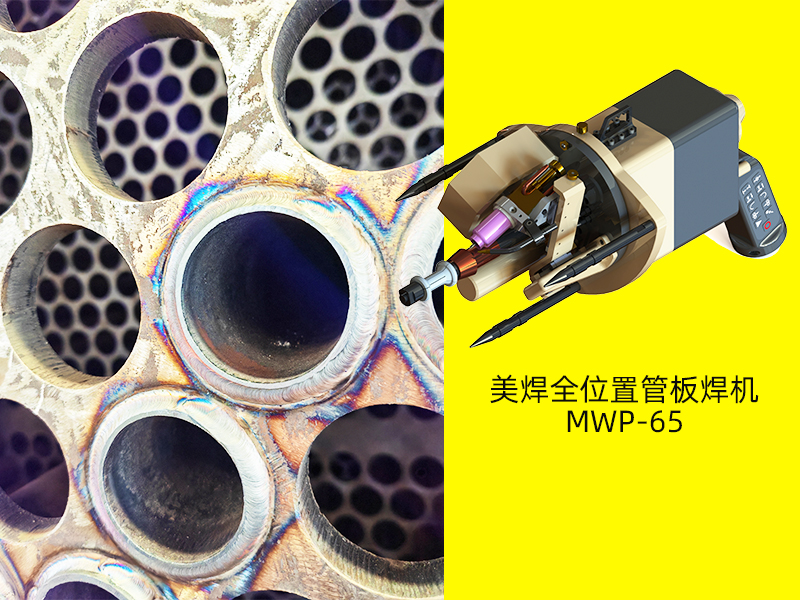

For more products and services such as automatic pipe-to-pipe welding machines, automatic tube-to-plate welding machines, automatic circular seam welding special machines, and hot wire surfacing systems, please call: 18918961606 or visit the official website of Shanghai Mwelding: https://www.mwelding.com.cn