Problem Description

In recent years, with the increasing improvement of steel structures, the construction of offshore oil fields has developed rapidly, and a large number of ocean engineering projects such as offshore oil platforms and jackets have been manufactured and put into use. There are often small-angle welds in ocean engineering structures, which are difficult to weld. After welding and ultrasonic testing (UT), welding defects such as lack of fusion, pores, and slag inclusions are usually found at the root of the weld.

In shipbuilding and ocean engineering, in order to ensure welding quality, the welding inspection process consists of three links: pre-welding inspection, in-process welding inspection, and post-welding inspection. Welding inspection is divided into destructive testing and non-destructive testing. Since welding inspection runs through the entire welding production process, the phenomenon of final product scrapping is greatly avoided, and the waste of raw materials and working hours is significantly reduced, and the economic losses caused by schedule delays are reduced, thus significantly improving social and economic benefits.

Problem Analysis

(1) Locations of welding defects

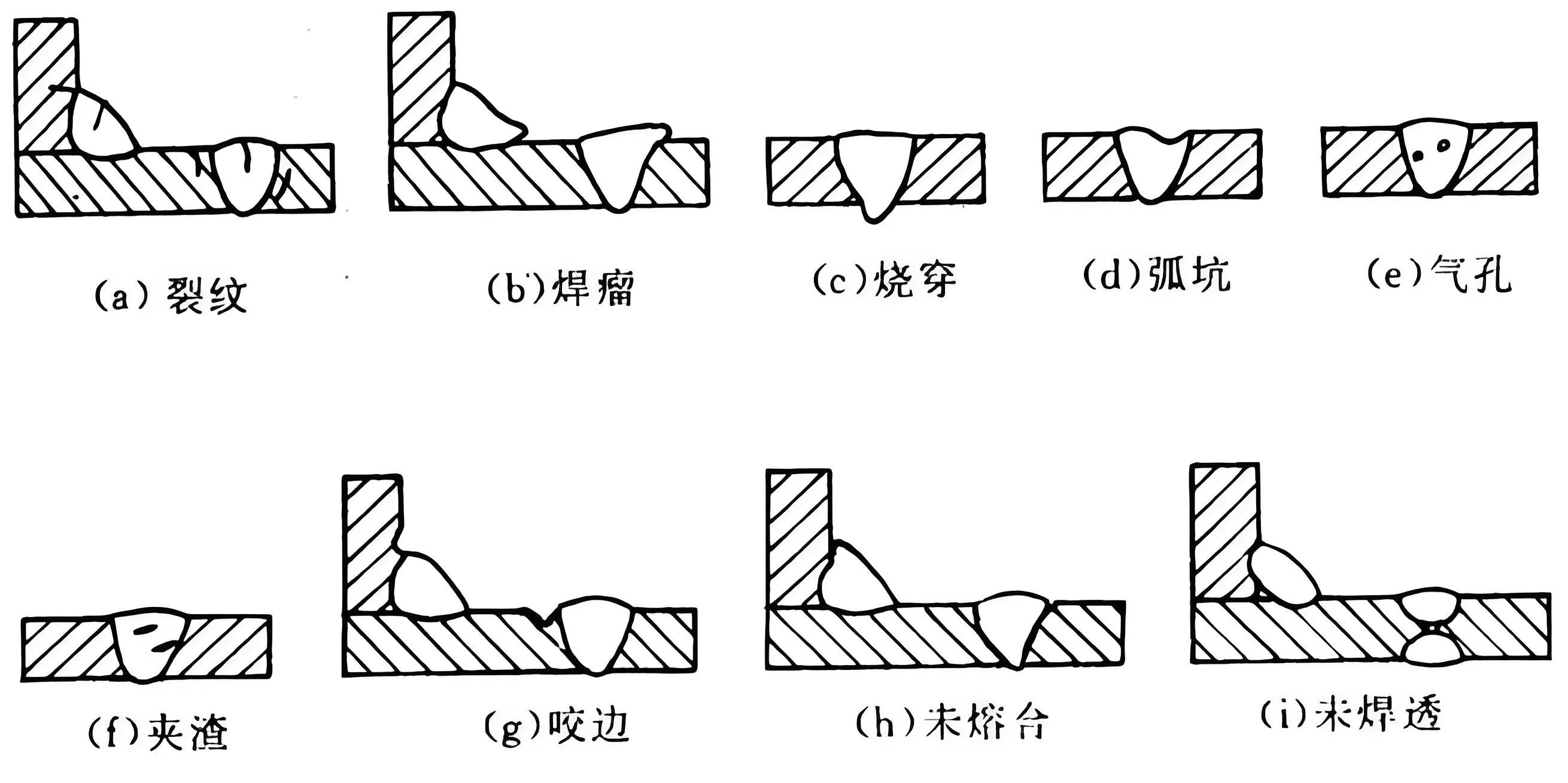

Toe welding defects: After welding, when radiographic testing (RT) or UT is performed on the weld, tiny cracks are usually found at the toe of the weld. The appearance of the weld is good when the welder is performing the root pass welding, but after grinding with a grinder, slag inclusions or irregularly shaped cracks may be found at the toe or root of the weld, especially when welding thick plates, pipe trusses, or intersecting joints, and this kind of defect is more obvious.

Filler layer defects: When filling welding, the internal quality of the weld does not meet the requirements mainly because the weld passes are not cleaned thoroughly between passes, resulting in welding defects such as slag inclusions, incomplete penetration, and undercut on both sides of the weld. If the middle of the weld pass is obviously convex, slag inclusions, lack of fusion, and other defects are very likely to occur during subsequent weld pass welding. To ensure the internal quality of the weld, the weld pass should be strictly ground after each layer of welding.

(2) Unqualified appearance quality of the weld

When inspecting the appearance of the weld, defects are usually found.

The size and shape of the weld do not meet the requirements: The appearance shape and size of the weld are inconsistent, and the reinforcement is uneven; the weld is too wide or too narrow, and the reinforcement is too high or too low; single-sided fillet welds, etc.

Arc crater: An arc crater is a sagging phenomenon at the end of the weld. The arc crater is often the part where the weld strength is severely reduced, and it is also the part where crater cracks often occur.

Undercut: Due to improper selection of welding parameters or incorrect operation techniques, the arc melts the base metal, and the depression or groove formed on the base metal along the toe of the weld is called undercut. Undercut reduces the effective cross-sectional area of the joint, weakens the strength of the welded joint, and more seriously, causes stress concentration. Structures under dynamic loads or alternating loads are prone to fatigue cracks at this location, resulting in structural failure.

Weld bead: A weld bead is a metal bead formed when the molten metal flows onto the surface of the unmelted base metal outside the weld during the welding process, and there is local lack of fusion at this place. A weld bead is also called overflow and often appears at horizontal, vertical, and overhead joints. A weld bead not only affects the appearance of the weld but also often conceals defects such as slag inclusions, incomplete penetration, and lack of fusion, and stress concentration is easily generated here, and it is easy to become the initiation source of fatigue cracks in a dynamic load service environment.

Surface cracks, slag inclusions, and pores:

① Microcracks that appear in the weld or heat-affected zone and can be observed with the naked eye or a magnifying glass are called surface cracks. The two ends of the crack are pointed and easy to expand.

② The slag remaining on the surface of the weld and rooted in the weld metal and not easy to fall off is called surface slag inclusion. Strip slag inclusions are more harmful to the performance of the weld.

③ Small holes on the surface of the weld are called surface pores, which can be single pores or continuous pores. A single large pore reduces the effective cross-sectional area of the weld and reduces the strength of the weld, and continuous pores are more harmful.

(3) Unqualified internal quality of the weld

Internal cracks: Cracks existing inside the weld or heat-affected zone are called internal cracks. Such cracks cannot be observed with the naked eye or a magnifying glass and need to be detected with special instruments and equipment. Special instruments and equipment mainly refer to X-ray flaw detectors, ultrasonic flaw detectors, etc.

Incomplete penetration: When fusion welding, the root of the weld is not completely penetrated, which is called incomplete penetration. This defect generally reduces the mechanical properties of the welded joint and is prone to cause cracks.

Lack of fusion: The incomplete melting and bonding between weld passes or between the weld pass and the base metal is called lack of fusion. This defect is easy to occur in welded joints of different plate thicknesses, and its main harm is to reduce the mechanical properties of the welded joint.

Internal pores: There are small holes inside the weld, either single or continuously distributed, which are called internal pores. The main harm of this defect is to reduce the mechanical properties of the welded joint.

Internal slag inclusions: The slag remaining inside the weld is called internal slag inclusions. This defect, like the pores inside the weld metal, is highly concealed and needs to be detected with special instruments and equipment. Internal slag inclusions also reduce the mechanical properties of the welded joint. Strip or continuous slag inclusions are easy to induce cracks, and the structure will fail when they expand to a certain extent.

Countermeasures

Use low-current multi-layer and multi-pass welding during filling welding, and the thickness of each layer of weld metal should not be too thick so that the gas in the weld pool can escape and avoid welding defects such as pores. To ensure the internal quality of the weld metal, strictly grind the weld pass after welding each layer of weld, and reserve a 1.5-2mm capping margin before capping welding to ensure the appearance of the weld.

During capping welding, welders should clearly understand the function of capping welding, and their skill levels should meet the standards to avoid welding defects such as undercut, too deep groove, and too large fillet weld on both sides of the weld due to welders' unclear understanding of the function of capping welding or insufficient operation skills, which will increase the workload of weld repair and lead to high production costs.

The welding cracks that appear at the root and surface of the weld are generally hot cracks, also called crystallization cracks. The causes are: there are low-melting eutectics in the molten pool, and tensile stress exists during the welding process. Therefore, before welding, the oil stains, rust spots, and other attachments on the weld groove should be strictly inspected and cleaned to prevent impurity elements from entering the welding molten pool to avoid forming a low-melting eutectic liquid film; strictly control the content of impurity elements such as C, S, and P in welding materials such as electrode coatings, fluxes, and welding wires; for components with large thickness, size, and rigidity, pay attention to self-restraint stress, structural stress, thermal stress, and residual stress during welding to prevent the weld from bearing large tensile stress during welding; for crater cracks, measures such as welding current attenuation and delayed stop of the shielding atmosphere should be taken for elimination.

Adopt reasonable welding methods and techniques to reduce welding stress and deformation. Be familiar with various welding materials and welding methods and their characteristics to reduce defects such as groove and fillet weld size that are too small or too large in the appearance of the weld. Before welding, ensure the assembly quality and clean the groove. If repair is required, ensure that the defects are completely removed before welding repair. The main measures to reduce welding stress are to ensure a reasonable welding sequence. For long welds, use segmented back welding; use hammering vibration to eliminate stress, etc. For welds with preheating and interpass temperature control requirements, do a good job of management and control; strictly implement the welding procedure specification.

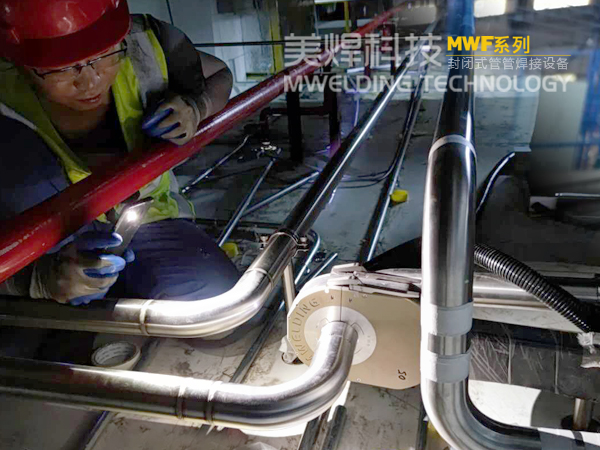

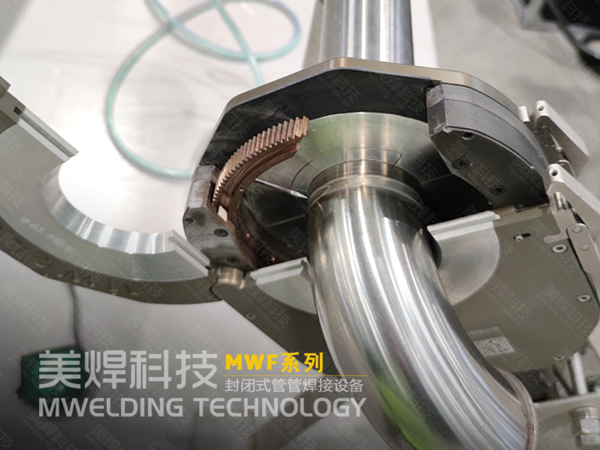

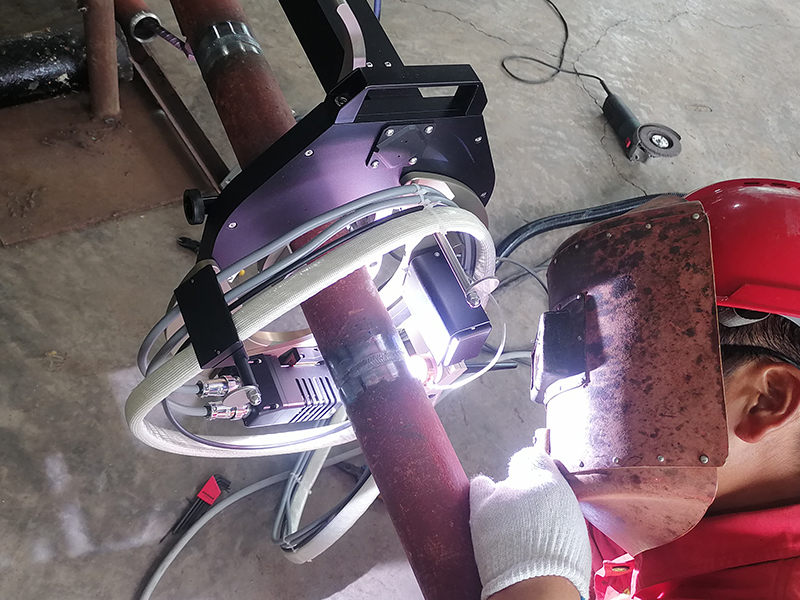

At the MWF-80 operation site, just put on the pipe and start welding, and start the expert welding parameters with one click.

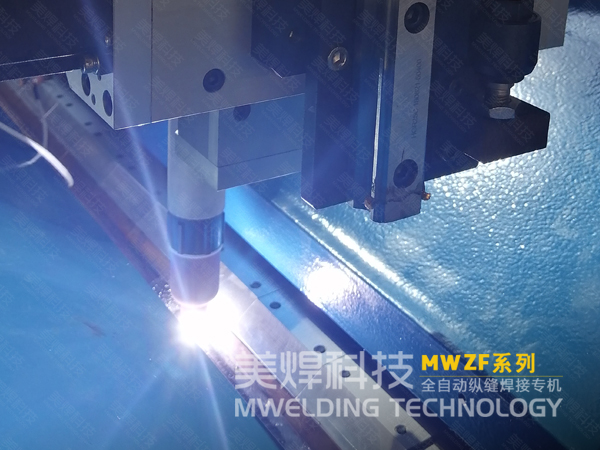

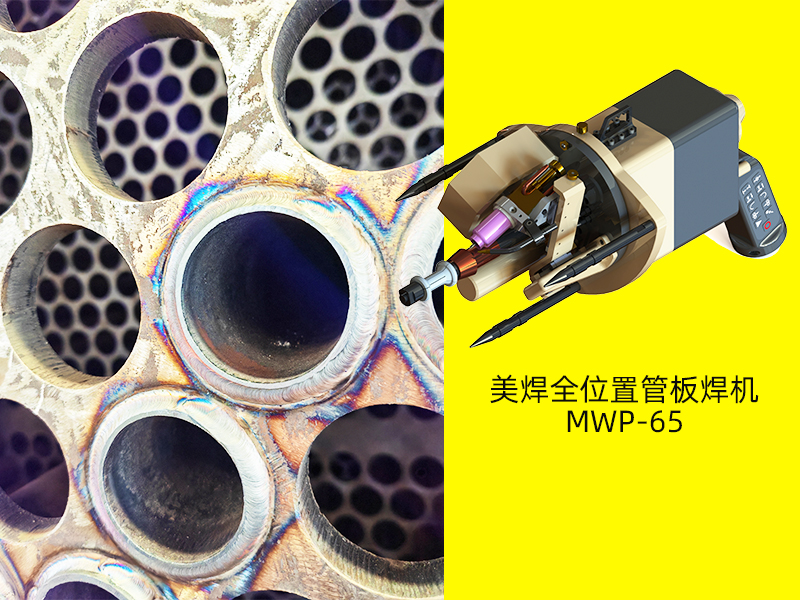

In short, rework due to welding defects will increase production costs. The Mwelding MWF series stainless steel pipe welding machine, as a professional thin-walled stainless steel welding machine, with its compact size and perfect one-side welding and two-side forming process, is widely used in the installation of pipeline equipment in fields such as food and pharmaceuticals, biological fermentation, water treatment, air conditioning and refrigeration, instruments and meters, pressure vessels, aerospace.

The product uses core components and materials imported from Germany, has a lightweight structure, is safe, precise, durable, and reliable, has a full-body water cooling system, and the gun body has 4-way gas protection. It has a high duty cycle and high stability, and is suitable for all-position welding of stainless steel clean pipes with a diameter of 6-168mm and a thickness of 2.5mm and below. It is an excellent and easy-to-use automatic welding machine for hygienic stainless steel clean pipes.

The weld is beautiful, and the Mwelding MWF series pipe welding machine completely solves welding problems such as arc craters, undercuts, and weld beads.

This equipment uses computerized digital control throughout the process and is equipped with an expert welding database, which enables operators to quickly get started and achieve the best welding effect. At the same time, the equipment can achieve continuous and accurate control of the welding process according to different welding materials, with excellent welding forming, stable output, and no harmful substances generated, meeting hygienic industry standards and customer requirements. It effectively solves the problems of unstable process, low efficiency of welding methods, and high welding rework rate in traditional manual pipe welding processes, greatly improving welding efficiency and welding technology, saving at least 30% of labor costs, and is a good helper for precision welding. It has been tested in the market for a long time and has received unanimous praise from customers!

One-side welding and two-side forming, both inside and outside are penetrated. The MWF series pipe welding equipment is inexpensive and easy to use.

Applicable pipe diameters:

MWF-12 is suitable for pipe diameters: Φ 4-12.7mm

MWF-40 is suitable for pipe diameters: Φ 6.0-38.1mm

MWF-80 is suitable for pipe diameters: Φ 12.7-76.2mm

MWF-120 is suitable for pipe diameters: Φ19.05-114.3mm

MWF-168 is suitable for pipe diameters: Φ50.8-168mm

Welding types:

Straight pipe - straight pipe, straight pipe - chuck, straight pipe - tee, straight pipe - elbow;

Chuck - elbow, chuck - tee, large U-bend, etc.