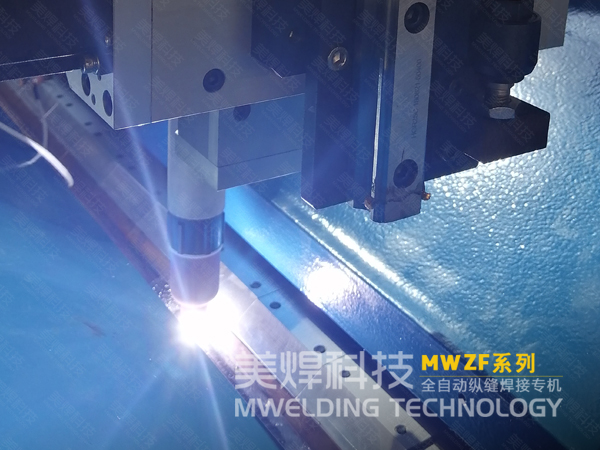

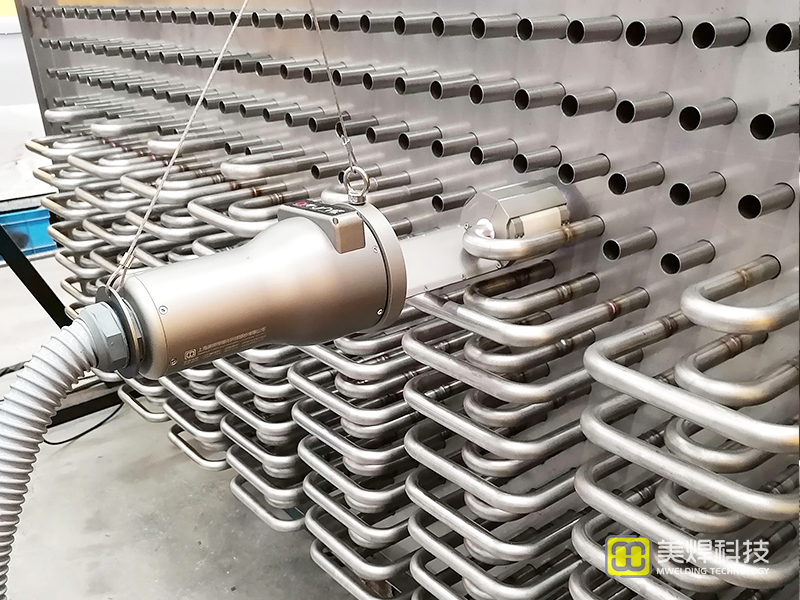

In the production of heat exchangers such as radiators and condensers, which feature a large number of dense piping, welding poses a bottleneck issue that significantly impacts overall production capacity. To effectively address this challenge, comprehensive consideration can be given to either upgrading process equipment or adjusting operational models. The introduction of advanced automatic welding equipment can significantly reduce welding time, increase the first-pass welding qualification rate, and effectively enhance welding efficiency. Meanwhile, the introduction of such equipment fundamentally changes the operational management model. Stable and controllable welding outputs contribute to refined management of large-scale operations. The operational model of one person managing two machines maximizes the utilization of personnel and assets, ensuring that efficiency is truly achieved.

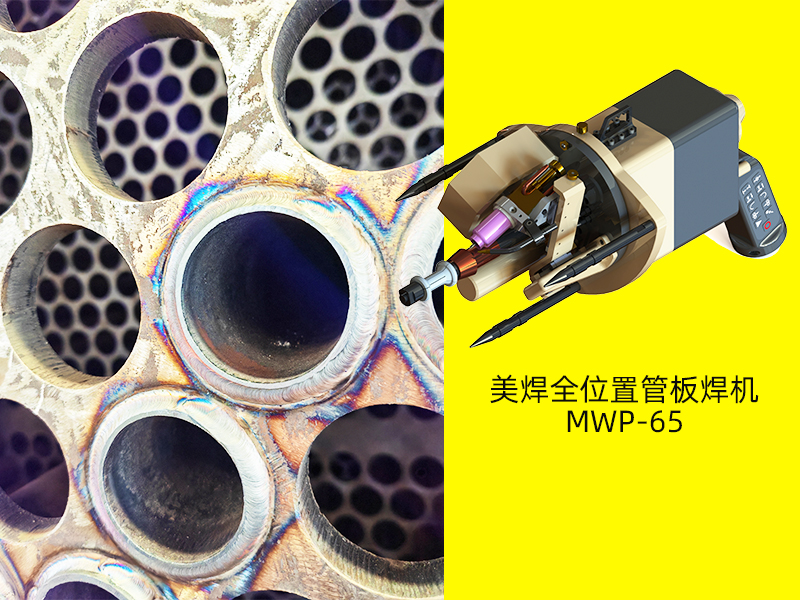

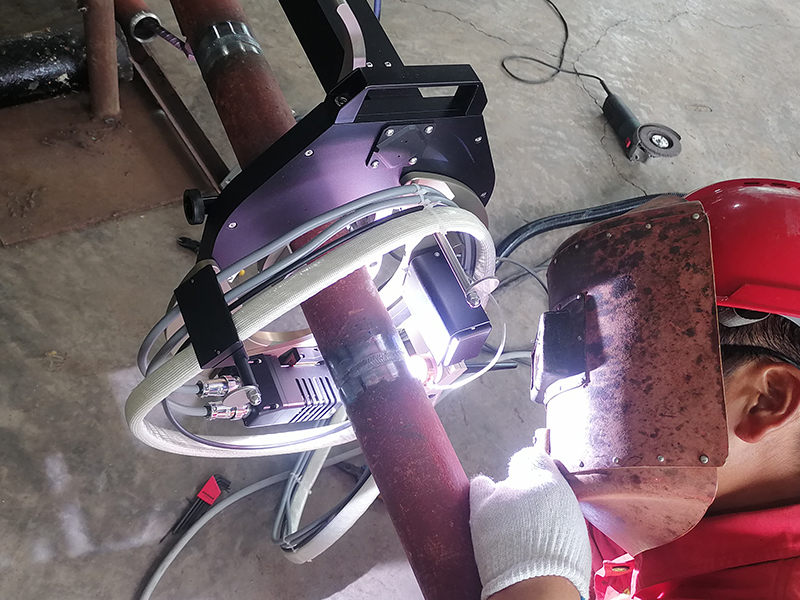

As a handheld automatic welding device, its compact size may initially raise doubts about its welding capabilities. However, such concerns are unnecessary. Currently, U-tube welders have mature market applications across multiple industries, and are commonly used for welding operations in medium to large heat exchanger companies and Sino-foreign joint ventures.

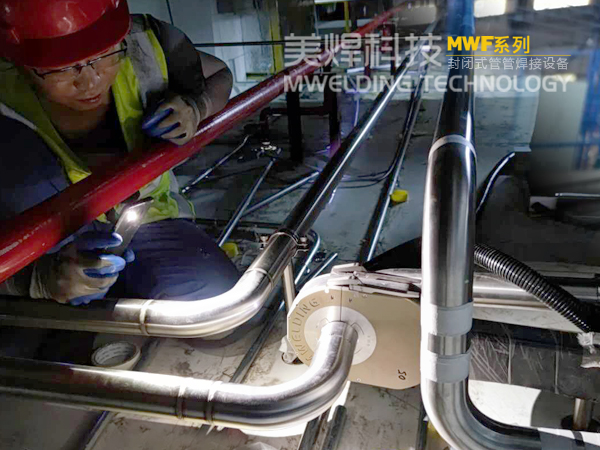

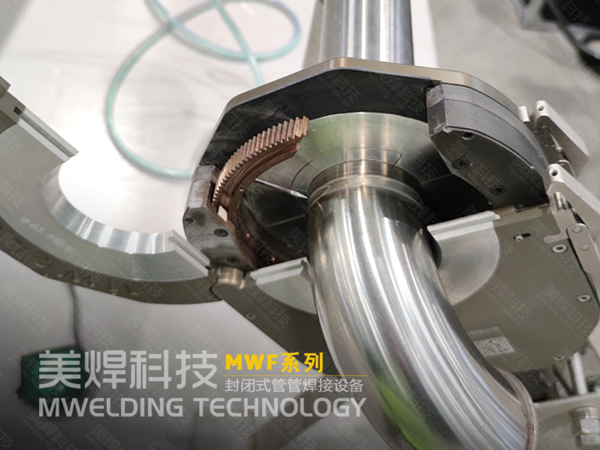

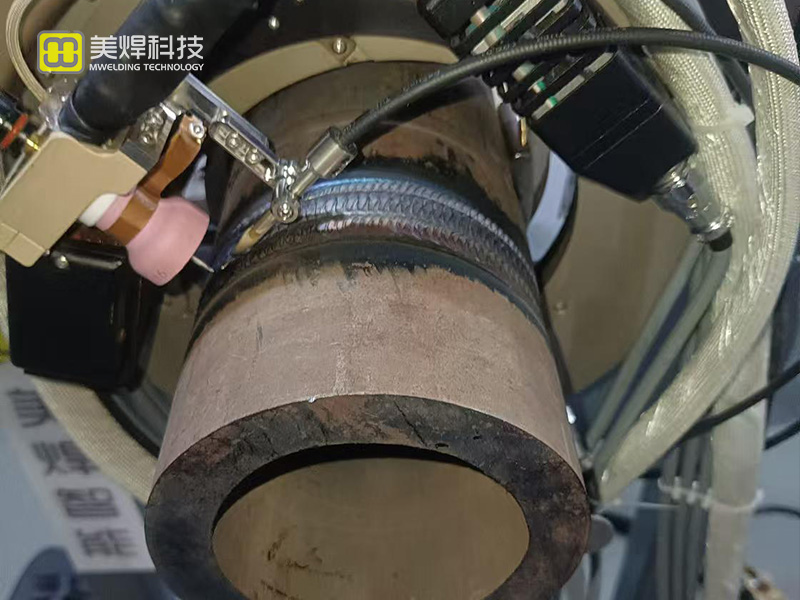

The MWH series of automatic welding equipment for U-tubes in heat exchangers utilizes advanced manufacturing technology for automatic welding equipment, condensing the entire argon arc welding process into a small handheld welding gun. During welding, the tungsten needle rotates around the workpiece's circular seam, automatically achieving welding. Throughout the process, the pipe melts by itself without the need for wire filling. Button-style operation is convenient and fast, resulting in a beautiful and sturdy weld, greatly reducing the dependence on skilled workers during the welding process.

Compared to traditional manual welding, it offers more stable and efficient welding performance, facilitates lean industrial management, and produces a more aesthetically pleasing appearance. Its excellent welding performance has been recognized by industry professionals and is widely used in HVAC and refrigeration equipment such as heat exchangers and condensers.

Mwelding Technology has developed the MWH series of U-tube welders for heat exchangers with proprietary intellectual property rights. This welding equipment is specifically designed for the welding of U-tubes in heat exchanger equipment, effectively addressing the welding bottleneck in industrial production. The product employs imported core component materials and boasts a compact structure that is safe, precise, durable, and reliable. Full-body water cooling enhances the welding gun's duty cycle. The MWH series of U-tube welders for heat exchangers from Mwelding are lightweight, compact, and easy to operate. A worker with no prior experience can learn to operate it in one hour, and later, one person can simultaneously operate two welding guns, effectively improving human efficiency and reducing labor costs. Multi-gas protection ensures welding quality, fully meeting the demands of surface cooler equipment industries and surpassing traditional tube-to-tube welding practitioners. It greatly demonstrates superior product craftsmanship and quality, enhancing product grades. Customization is supported, along with full-process technical services!

| Product Models | Welding Pipe Diameters |

| MWH-12A | Φ12.0mm-Φ13.5mm |

| MWH-16A | Φ12.7mm-Φ16.0mm |

| MWH-16AJSG | Φ12.7mm-Φ16mm |

| MWH-21A | Φ16mm-21mm |

| MWH-25A | Φ22mm-Φ25mm |

Custom U-tube welders are available upon request.

Since the product's market launch, feedback from customer manufacturers using the MWH series of U-tube welders for heat exchangers from Mwelding has been positive. The custom-made U-tube welders for their welding requirements have demonstrated very stable welding effects, beautiful weld seams, and high welding efficiency. Compared to previous manual welding, the need for rework has decreased, and efficiency has naturally increased. In addition, welders have transitioned from technician-level to general worker status, significantly reducing labor costs and making management easier. For U-tube welding in the HVAC and refrigeration industry, the MWH series of U-tube welders for heat exchangers from Mwelding is indeed a great choice. With increased production efficiency and improved quality, orders have subsequently increased.