In the production fields of heat exchangers, refrigeration equipment, and surface coolers, the welding precision of header pipes and straight pipes is a core factor determining equipment performance. The MWHP-12AC, MWHP-16AC, and MWHP-16DC header pipe socket welding equipment for heat exchangers launched by MWelding Technology has become a high-quality solution in the refrigeration industry due to its precise technical design, efficient performance, and rigorous process standards.

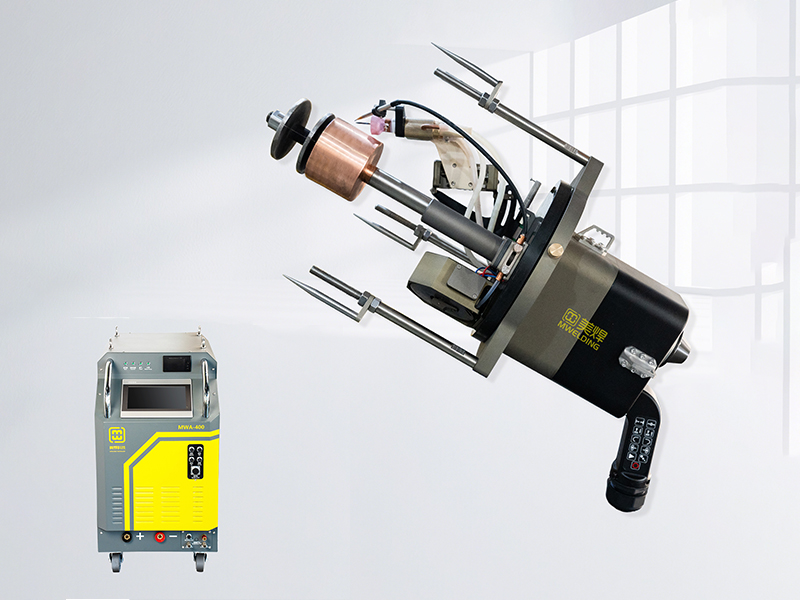

The core of the equipment consists of MWHP series welding torches and MWA-200 integrated control power supplies, which work together to achieve high-quality socket welding. The welding torch is made of polymer insulating materials and aluminum alloy structure, weighing only about 2KG (excluding cables), balancing light weight and durability. The fully enclosed design enables directional multi-channel gas protection, reducing gas filling time while ensuring neat weld appearance. The full-body water cooling system significantly improves the equipment's duty cycle, meeting the needs of long-term operation. The control power supply integrates three systems, weighing approximately 18 kg, and its integrated water, electricity, and gas configuration facilitates on-site and high-altitude operations. Equipped with a 10-inch color touchscreen and a graphical step-by-step interface, it is easy to operate. It supports the storage of thousands of sets of parameters and one-click printing, and has a built-in expert system—users only need to input the pipe diameter and wall thickness to automatically generate parameters, lowering the operation threshold.

In terms of technical parameters, this socket welding equipment is highly targeted:

MWHP-12AC: Applicable pipe diameter Φ12-12.7mm

MWHP-16AC: Applicable pipe diameter Φ15-16mm

MWHP-16DC: Applicable pipe diameter Φ15-16mm

It matches the wall thickness requirements of header pipes (2-3mm) and welding straight pipes (0.8-1mm), uses argon as the protective gas, has a tungsten electrode diameter of 1.6mm, and is equipped with a standard 6m cable. The control power supply has comprehensive protection functions, including motor overload protection, water flow detection, etc. The welding current range is 3-200A, the arc initiation method is high-voltage pulse, the current accuracy is 1A, and it can set parameters in 8 intervals to adapt to various processes.

The welding process is even more rigorous: there shall be no obstacles within 30mm centered on the pipe fitting; the distance from the flanged edge of the header pipe socket to the top of the U-bend shall be >45mm; the pipe orifice must be trimmed to ensure a flat surface, with a perpendicularity error of ±1°; the socket pipe shall have no gaps and must be tightly fitted, with an ovality of ≤3‰; the insertion depth shall be ≥6mm; the straightness error between the straight pipe and the socket shall be ≤0.3mm, and the perpendicularity error shall be ≤5°; when welding stainless steel, argon shall be filled inside the pipe to prevent oxidation, ensuring weld quality through detailed controls.

Safe operation cannot be ignored. Before using the equipment, professional electricians must connect the single-phase three-core power cable in accordance with national standards. The yellow-green wire is the grounding wire and must be firmly grounded; otherwise, the equipment is strictly prohibited from operation, providing a safety guarantee for operation.

With the advantages of standardization and intelligence, the MWHP series socket welding equipment not only solves the precision problem of header pipe socket welding but also reduces production difficulty. MWelding Technology will continue to promote the upgrading of welding processes in the refrigeration industry, providing solid support for the production of high-quality equipment.