In high-end manufacturing fields such as semiconductors, biopharmaceuticals, and food chemical engineering, clean fluid pipelines are the "lifeline" that ensures production precision and product purity, while the welding quality of thin-walled pipelines directly determines the sealing performance and cleanliness of fluid transportation. Recently, Meihan Technology announced that its autogenous welding technology for clean fluid thin-walled pipelines has completed a new round of upgrades, successfully overcoming the welding challenge for pipelines with wall thickness increased from 2.5mm to 3.5mm, and providing a more efficient and reliable technical solution for the construction of fluid systems in high-end manufacturing.

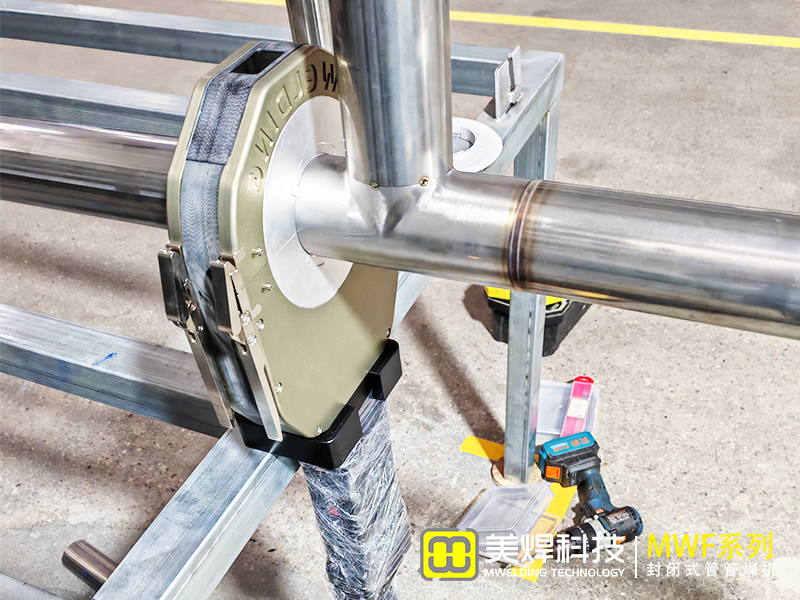

Meihan's Clean Pipeline Welding Machine Series, covering pipe diameters from 3mm to 168mm and wall thicknesses from 2.5mm to 3.5mm

Previously, the welding of clean fluid thin-walled pipelines has long faced three major pain points: "difficult precision control", "easy deformation", and "substandard cleanliness". Especially when the pipeline wall thickness is less than 5mm, traditional welding technologies tend to cause pipe wall penetration and uneven weld beads due to concentrated heat sources. Moreover, the oxide layers and impurities generated during the welding process can contaminate fluid channels, failing to meet the stringent requirements of "nano-level cleanliness" in the semiconductor industry and "aseptic transportation" in the biopharmaceutical industry. For this technological upgrade, Meihan Technology focused on optimizing heat source control and molten pool stability for autogenous welding.

Capable of welding straight pipes, elbows, tees, flange seats, saddle joints, etc. with aesthetically pleasing welds that meet Level I flaw detection standards

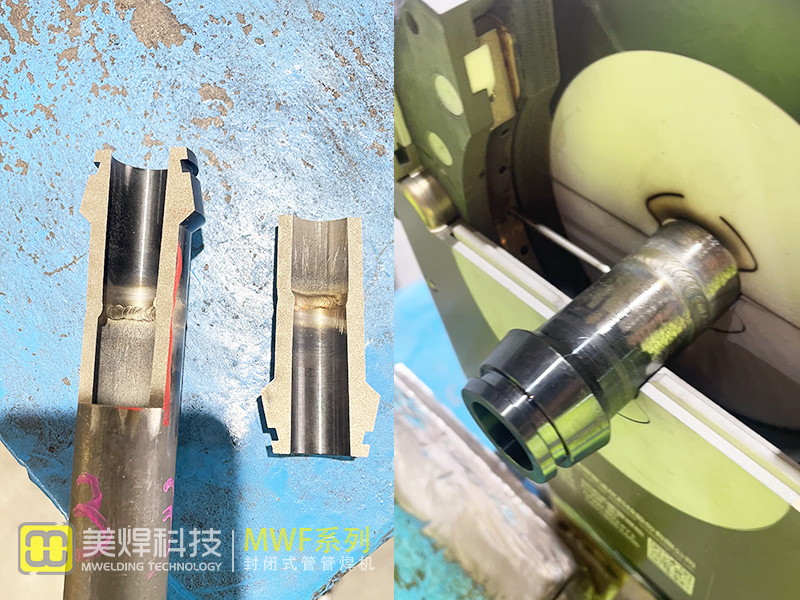

By developing a new high-frequency induction heat source system, Meihan Technology has achieved millisecond-level precise control of welding temperature. It can automatically match heating curves according to the material properties of 3.5mm thin-walled pipelines (such as 316L stainless steel, Hastelloy, etc.), avoiding pipe wall deformation caused by local overheating. At the same time, the company has innovatively introduced inert gas-protected molten pool technology, which forms a closed protective atmosphere in the welding area to effectively inhibit oxidation reactions. After welding, the inner wall roughness of the pipeline is Ra ≤ 0.8μm, meeting the highest-level cleanliness requirements specified in the ISO 2037 standard.

One-time forming for 3.5mm-thick pipes, with aesthetically pleasing welds that feature uniform penetration from the inside out, applicable for welding metal pipes of various materials

In application scenarios, this new breakthrough has demonstrated significant advantages. For instance, in semiconductor wafer manufacturing workshops, after adopting Meihan's new solution for high-purity nitrogen pipelines with a 3.5mm wall thickness, the welding efficiency has increased by 40%, and the pipeline leakage rate has been controlled below 1×10⁻⁹ Pa·m³/s, which is far superior to conventional industry standards. In the biopharmaceutical field, the welding process of medical fluid transportation pipelines does not require subsequent pickling and passivation treatment, reducing the risk of secondary pollution and helping enterprises shorten production cycles.

Capable of meeting welding requirements under complex and variable working conditions, such as high-altitude, outdoor, and dense pipeline welding and installation

As a domestic technological leader in the clean welding field, Meihan Technology's this breakthrough not only fills the domestic technological gap in autogenous welding of 3.5mm thin-walled clean pipelines but also breaks the monopoly of foreign similar technologies. In the future, Meihan Technology will continue to focus on the fluid system needs of the high-end manufacturing field, promote the upgrading of clean welding technology towards a thinner-walled, more efficient, and more intelligent direction, and provide technical support for the high-quality development of China's strategic emerging industries such as semiconductors and biopharmaceuticals.