On November 18, 2025, the highly influential CDCE Data Center Exhibition in China's data center sector grandly kicked off at the Shanghai New International Expo Center. Focusing on the core needs of green and intelligent data center construction, this exhibition gathered high-quality enterprises and cutting-edge technologies from the entire industrial chain. Shanghai MeiHan Technology made a wonderful appearance with a variety of customized automated welding equipment and integrated solutions for data center scenarios, attracting widespread industry attention with its precise and efficient technical advantages.

Founded in 2012, MeiHan Technology is a professional R&D enterprise specializing in intelligent welding equipment. With more than ten years of deep cultivation in the field of automated welding, it leverages Shanghai's talent and policy advantages to establish in-depth cooperation with welding research institutes and major universities. The company has accumulated rich technical experience in industries such as power, energy, chemical engineering, and refrigeration. For this exhibition, MeiHan accurately targeted the welding needs of key parts in data center construction, such as heat dissipation systems and energy supply pipelines, focusing on displaying four core product systems to fully demonstrate how welding technology safeguards the engineering quality of data centers.

At MeiHan Technology's booth, the closed pipe-to-pipe welding equipment MWF-80 became one of the highlights. This equipment supports welding pipe diameters of Φ12.7-76.2mm, and the product series covers thin-walled pipe welding with diameters ranging from 3.17-219mm. Adopting a double-seal design for sufficient welding protection, its flexible self-centering fixture can easily achieve precise positioning. It is particularly suitable for welding thin-walled carbon steel and stainless steel pipes such as data center radiator condenser tubes.

According to on-site technical personnel, this equipment adopts the fusion welding method, which can effectively improve welding tightness and avoid equipment failures caused by pipe leakage. Meanwhile, its portability can meet the diverse needs of on-site prefabrication, installation, and maintenance.

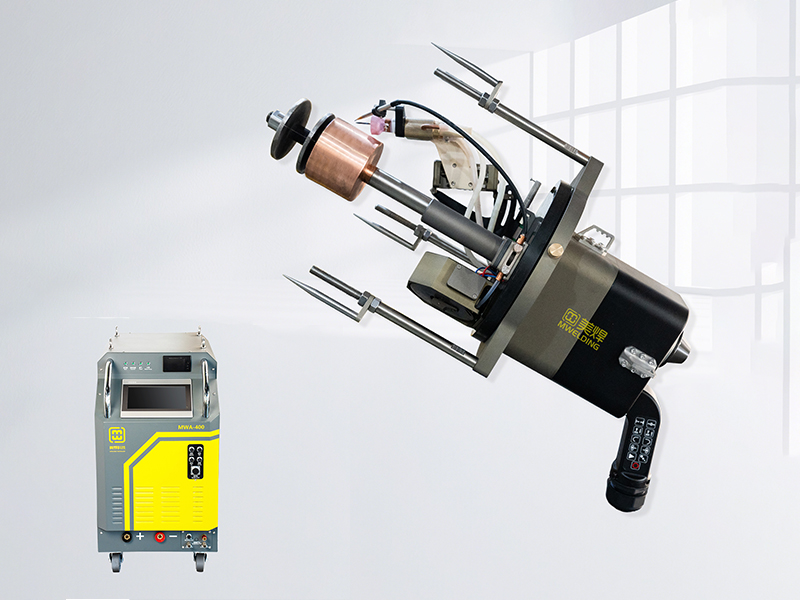

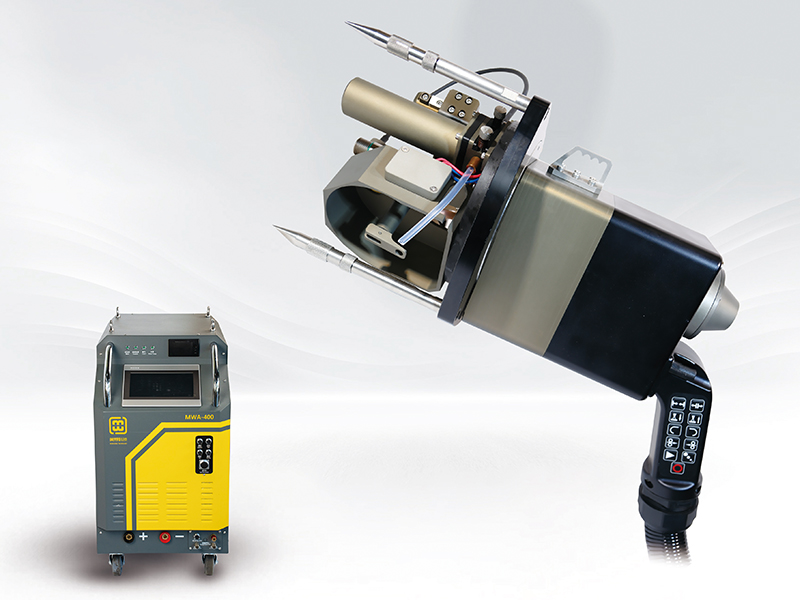

For the medium and thick-walled pipe welding scenarios in data centers, the open pipe-to-pipe welding equipment MWG-90 exhibited by MeiHan Technology also performed brilliantly. Constructed with an aluminum structure, the equipment features a lightweight and compact design. Equipped with stepless adjustable caliper-type fixtures, the product series can cover pipe diameters of Φ19-325mm. The gapless gear transmission design ensures stable rotation, and combined with arc length and weaving functions, it can perfectly meet the multi-layer and multi-pass welding requirements of various joint forms such as pipe-to-pipe, pipe-to-elbow, and pipe-to-flange. The welding quality of the data center pipeline system is directly related to operational stability. Our equipment can accurately implement welding parameters through the PLC intelligent control system, avoiding human operation errors.

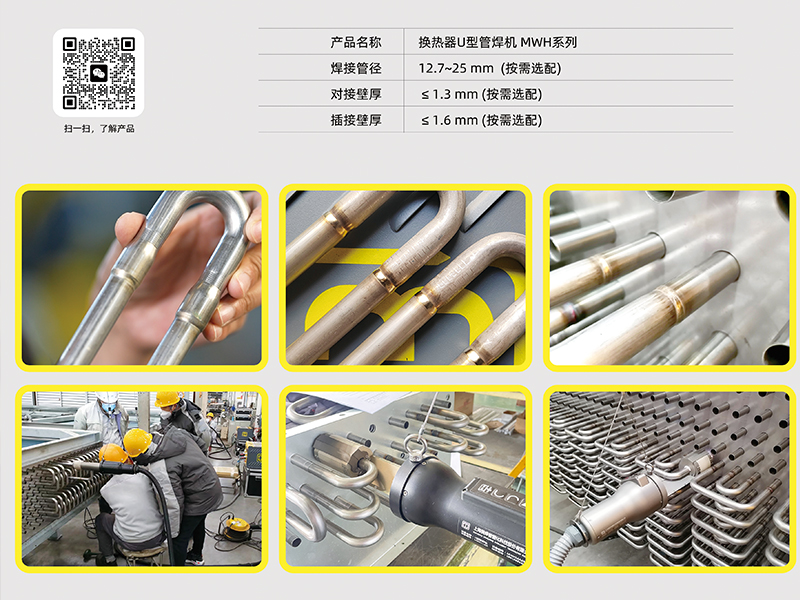

The pipe-plate welding equipment MWP-65 and heat exchanger U-tube welding machine MWH-12 displayed simultaneously on-site further improved the data center welding solution. Among them, the MWH-12DA welding machine, highly recognized by customers, is specially designed for welding small-spacing radiators. Adopting DC and radial dual-air path drive technology, it can precisely control weld quality. Its intelligent touch screen operation interface not only lowers the operation threshold but also is equipped with overvoltage protection, leakage protection, and fault prompt functions to fully ensure construction safety. It is understood that this equipment has applied for a national patent and can reduce production costs for the welding of heat exchangers in data center refrigeration systems.

MeiHan Technology's products have long been favored by the market for their precision, efficiency, durability, simple operation, and high cost-performance ratio. From standardized to non-standard welding equipment, and from professional welding equipment for small-diameter pipes used in instruments to large-diameter pipes in petrochemical industry, the main product series complement each other to meet the market demand in the field of pipe welding. The products are widely used in high-end manufacturing fields such as instruments and meters, food and pharmaceutical machinery, air conditioning and refrigeration, energy boilers, water treatment and environmental protection, construction machinery, petrochemical industry, aerospace, military industry, and nuclear power. Through the integration of production, education, and research, MeiHan continuously conducts in-depth R&D and innovation in the welding field, opening a new milestone in high-end manufacturing in terms of welding robot technology.