To meet the high-standard requirements for tube-sheet welding across various industries, Meihan Technology proudly launches the MWP-102 Tube-sheet Welding Equipment with great fanfare. Leveraging core advantages of modular design, intelligent control and multi-scenario adaptability, it creates an all-new solution for all-position large tube-sheet TIG welding!

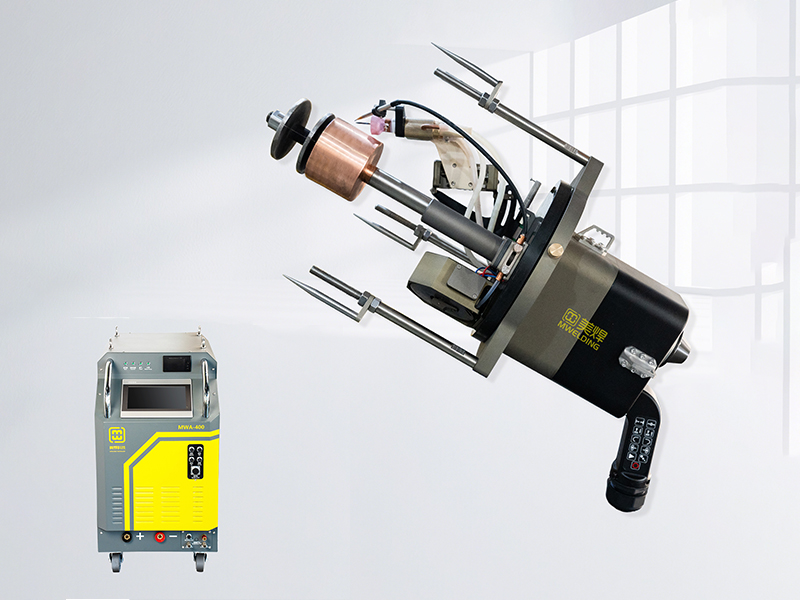

The MWP-102 Tube-sheet Welding Equipment is composed of the MWP-102 All-position Tube-sheet Welding Torch and the MWA-400 Integrated Control Power Supply. Adopting a modular design concept, it features a compact structure, easy operation and high reliability. Exclusively built for all-position TIG welding of tube-plate structures, it supports two welding forms: tube protrusion and tube flush. Equipped with a pneumatic elastic expanding core fixture, it delivers stable clamping performance and easily adapts to the tube-sheet welding requirements of various materials and specifications, boosting production efficiency for industries of all types.

Powerful Performance, Unlocking a New Tube-sheet Welding Experience

Starting from the pain points of actual production, the MWP-102 Tube-sheet Welding Equipment boasts multiple core performance advantages, which greatly reduce operational difficulty, improve welding quality and efficiency, making tube-sheet welding simpler and more precise.

✅ Pneumatic expanding core positioning for firm clamping and hassle-free operation : Adopting a pneumatic expanding core method, it can accurately fix the welding torch at the center of the pipe fitting with stable clamping effect, eliminating the need for additional adjustment by welders, greatly simplifying operational difficulty and ensuring welding concentricity.

✅ Multi-form & multi-material adaptability with wide scenario coverage : Supporting tube protrusion and tube flush welding, it enables two welding methods: autogenous welding and filler wire welding. Perfectly adapted to the tube-sheet welding of common materials such as carbon steel and stainless steel, it meets diverse production needs.

✅ Integrated structural design for neatness and durability : Water, gas and electricity are transmitted internally with no external wire and pipe entanglement, eliminating operational troubles and fault risks caused by messy pipelines; the welding torch is equipped with a built-in wire feeder that can hold a 1KG welding wire spool, saving operating space and enabling convenient wire replacement.

✅ Water circulation cooling for efficient continuous operation : Equipped with a cooling water circulation system, the equipment's duty cycle is greatly improved, meeting the demand for long-time continuous welding and adapting to the high-efficiency rhythm of industrial production.

✅ Ergonomic design for safe and user-friendly operation : The overall structure is optimized with ergonomic design, ensuring smooth operation and high safety. Meanwhile, the welding torch handle is equipped with operation buttons for one-click operation, significantly improving work efficiency.

Precise Parameters, Laying a Solid Foundation for Welding Quality

Excellent technical parameters are the core guarantee for the stable operation of the equipment and the qualification of welding quality. The MWP-102 Tube-sheet Welding Equipment achieves precise control in specifications and performance, escorting high-quality welding:

Intelligent Companion, Empowered by MWA-400 Integrated Control Power Supply

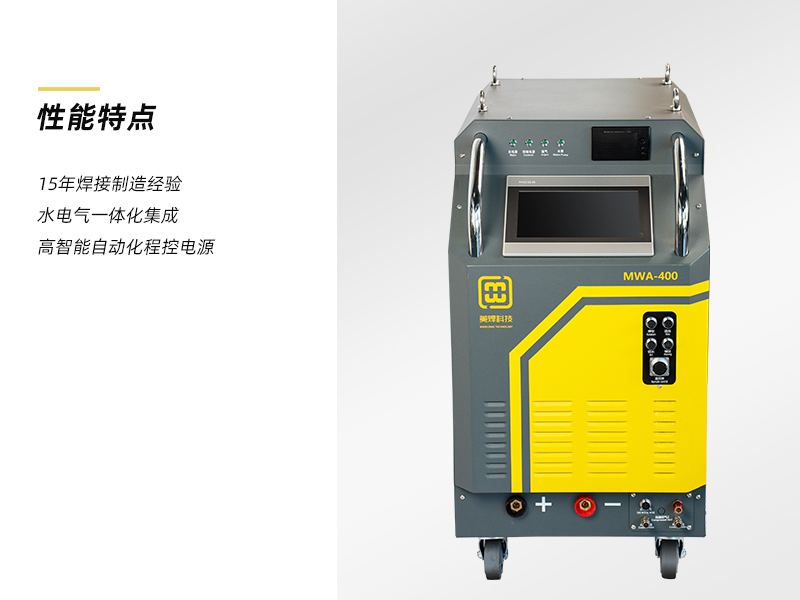

A good horse needs a good saddle. The efficient operation of the MWP-102 All-position Tube-sheet Welding Torch cannot be separated from the intelligent support of the MWA-400 Integrated Control Power Supply. As a patented design product, this control power supply features its appearance and structure designed by a renowned American professional industrial design company, presenting a rational and elegant look with high practicality. Its internal structure is rationally laid out, easy for on-site movement, installation and operation, providing stable and precise control support for the welding torch.

✅Equipped with an intelligent PLC control system to ensure the accurate and rapid operation of welding process parameters; it is fitted with a 10-inch color touch screen with a graphical and step-by-step interface design, enabling simple and fast operation that even novice users can master quickly.

✅It can real-time monitor core parameters such as current, voltage, rotation speed and oscillation speed during the welding process, and supports the configuration of a printer to print welding parameters at any time, facilitating process comparison and optimization.

✅It has a complete interval division and parameter storage function, which can set parameters in 12 intervals and store 80 sets of process parameter codes. Parameters for different welding processes can be quickly retrieved and modified, adapting to multi-batch and multi-specification production.

✅It supports the welding simulation function, which can predict the actual effect of parameter application in advance, avoid welding problems in a timely manner and reduce trial welding losses.

Excellence in Craft, Flawless in Welding; Prosper the Nation with Technology, Boundless in Innovation

Welding independent of the traditional experience of senior welders,

Realizing arc length tracking welding technology,

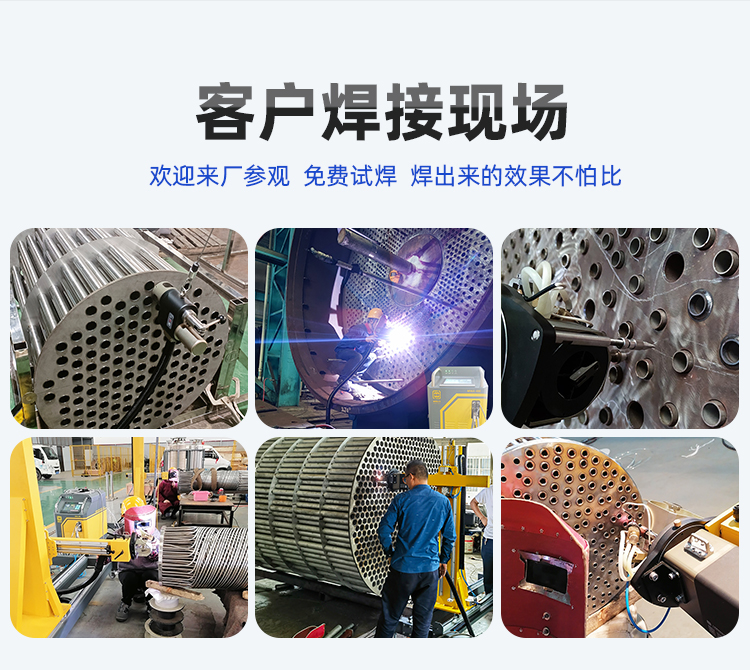

Whether it is the high standards of nuclear power tube-sheet welding,

Or the dense and complex honeycomb hole welds of heat exchangers,

Let every weld mark be the signature of Meihan!