In the field of petroleum energy transportation, the quality and efficiency of pipeline welding are directly related to the safety and stability of energy transmission. As a leading enterprise deeply engaged in the R&D of welding equipment, Shanghai MeiHan has launched an open-type petroleum pipeline welding machine. Relying on innovative technology and outstanding performance, it has become a core equipment in the industry that breaks through the limitations of traditional welding. Especially in the field of thick-walled pipeline welding, it takes a leading position among similar products in the industry with its 25MM wall thickness welding capability.

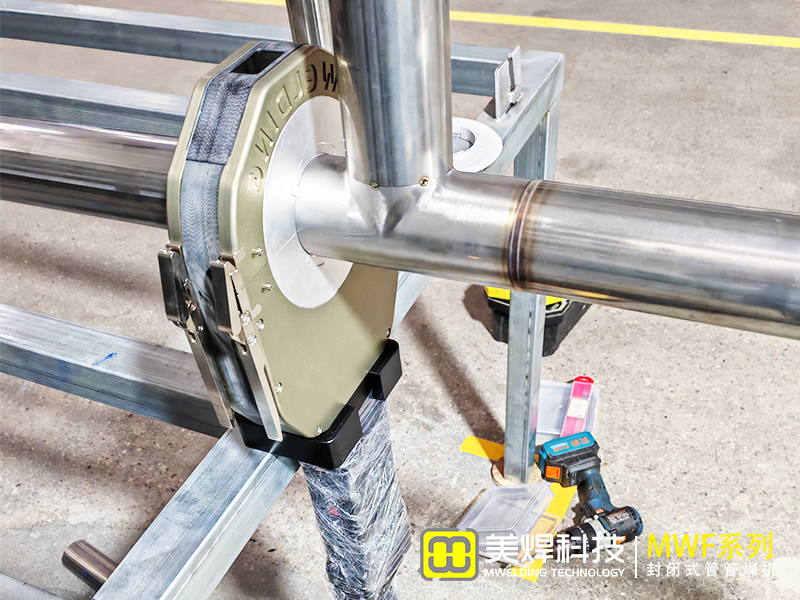

MeiHan Open-Type Pipeline Welding Machine for High-Altitude Operation

The most prominent advantages of this open-type petroleum pipeline welding machine lie in its "open-type" design, super-strong thick-walled welding capability and wide pipe diameter adaptability. Different from the restrictions of the closed structure of traditional welding machines on welding scenarios, it can flexibly cover the full range of welding pipe diameters from 20 to 325MM. Whether it is small-diameter precision pipelines or large-diameter main pipelines, it can be accurately adapted. At the same time, it can realize high-intensity operations with a welding wall thickness of 25mm, easily coping with petroleum pipeline welding challenges of different specifications and working conditions — from the maintenance of 20MM small-diameter pipelines in factories to the laying of 325MM large-diameter thick-walled pipelines for long-distance field transportation, it can achieve convenient and efficient operations.

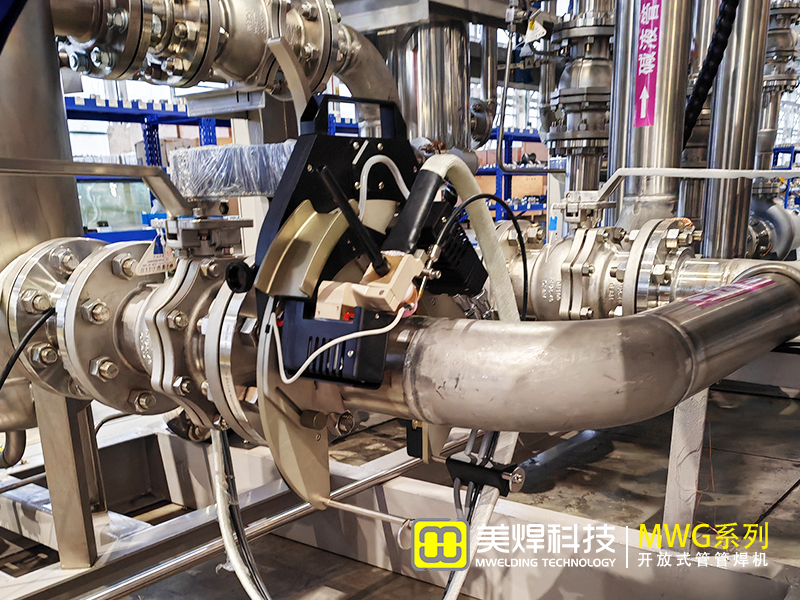

One Operator Controlling Multiple MeiHan Open-Type Pipeline Welding Machines in the Factory

At the same time, the equipment is equipped with a multi-layer, multi-pass fully automatic 360-degree welding system. Combined with an intelligent control system, it can monitor key parameters such as welding current and voltage in real time, automatically adjust the welding process, and accurately control the forming quality of each weld. This effectively avoids welding defects caused by human operation errors, not only increasing the welding qualification rate to over 99%, but also stably meeting the Level 1 flaw detection standard, which satisfies the strict quality requirements of petroleum pipelines in high-pressure and high-risk environments.

MeiHan Open-Type Pipeline Welding Machine for Clamping Welding of Dense Pipelines

In terms of performance, the welding machine adopts an energy-efficient welding power supply, reducing energy consumption by 15% compared with traditional equipment. At the same time, it has super strong wind and dust resistance. Even in severe cold conditions of -30℃ or high-temperature and sandy environments, it can still maintain stable operation, perfectly coping with the challenges of complex field environments in petroleum pipeline construction. In addition, the equipment is equipped with a digital management module, which can realize real-time storage and remote transmission of welding data, providing accurate data support for project quality traceability and later maintenance.

High-Quality Operation of MeiHan Open-Type Welding Machine in the Field

From the perspective of industry value, Shanghai MeiHan's open-type petroleum pipeline welding machine not only builds a full-scenario and high-precision welding solution with its 20-325MM pipe diameter coverage, 25mm thick-walled welding capability, fully automatic 360-degree welding technology and Level 1 flaw detection standard, but also promotes the transformation of welding operations towards intelligence and greenization. Its wide application has built a solid technical barrier for the safe transportation of petroleum energy in China, and also provided a "Chinese solution" for the innovative development of global petroleum pipeline welding equipment.