In pipeline installation projects, when faced with complex and variable working environments such as high altitudes, depressions, outdoors, and indoors, a high-performance and portable welding equipment can often become a valuable assistant for construction teams. The MWF series and MWG series pipe-pipe welding equipment developed by Shanghai MeiHan Intelligent Technology Co., Ltd. have become the ideal choice for pipeline welding in many industries due to their excellent welding quality, convenient operation experience, and wide applicability.

Two Series of Equipment, Accurately Matching Different Welding Needs

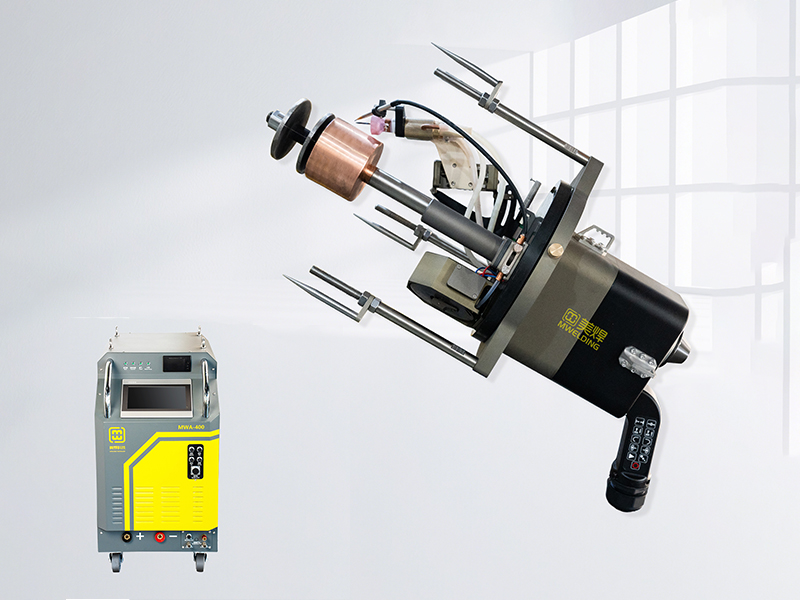

MeiHan Technology's automatic pipeline welding equipment is divided into MWF series closed pipe-pipe welding machines and MWG series open pipe-pipe welding machines, which respectively target the welding needs of thin-walled and medium-thick-walled pipelines, achieving professional segmentation.

MWF Series Closed Pipe-Pipe Welding Machine

This series is mainly applicable to the welding of thin-walled pipelines such as stainless steel, carbon steel, and titanium alloy with a wall thickness of ≤ 3mm. It is equipped with an intelligent digital welding control system and an expert database, which can ensure good welding formation. The finished product can meet the welding requirements of sanitary-grade stainless steel clean pipelines, which is particularly important for industries such as food fermentation and biopharmaceuticals that have extremely high requirements for pipeline cleanliness.

In terms of applicable pipe diameters, the MWF series offers a variety of models:

• MWF-12 is suitable for pipe diameters of Φ3.17-12.7mm

• MWF-40 is suitable for pipe diameters of Φ6.35-38.1mm

• MWF-80 is suitable for pipe diameters of Φ12.7-76.2mm

• MWF-120 is suitable for pipe diameters of Φ19.05-114.3mm

• MWF-120 is suitable for pipe diameters of Φ50.8-168mm

The MWF series can easily handle various welding tasks, whether it is the connection between straight pipes, the welding of straight pipes with chucks, tees, elbows, or even complex welding forms such as chucks with elbows, chucks with tees, and large U-bends.

MWG Series Open Pipe-Pipe Welding Machine

For medium-thick-walled pipelines such as stainless steel, carbon steel, and titanium alloy with a wall thickness of 2~12mm, the MWG series open pipe-pipe welding machine demonstrates strong performance. It adopts computer digital control throughout the process and is also equipped with an expert welding database for automatic pipe-pipe welding, enabling operators to quickly get started and achieve the best welding results. The welding formation is good and stable, meeting the requirements of level II flaw detection, and plays an important role in fields such as petrochemicals and pipeline installation that have strict requirements for welding quality.

This series also has a rich range of applicable pipe diameters:

• MWG-52 is suitable for pipe diameters of Φ32-51mm

• MWG-90 is suitable for pipe diameters of Φ20-89mm

• MWG-170 is suitable for pipe diameters of Φ63-168mm

• MWG-230 is suitable for pipe diameters of Φ89-230mm

• MWG-325 is suitable for pipe diameters of Φ159-325mm

Similar to the MWF series, the MWG series also has wide applicability in welding types, capable of completing various welding combinations between straight pipes and various pipe fittings, as well as between pipe fittings.

Outstanding Advantages, Improving Welding Efficiency and Quality, Efficiently Solving Welding Problems in Complex Environments

MeiHan's MWF and MWG series automatic pipeline welding machines have gained wide recognition in the market due to their many prominent advantages:

Reliable core components: Adopting imported German core components, ensuring the precision, efficiency, and durability of the equipment, while having high cost performance.

Simple and easy to operate: The one-key operation design allows zero-based personnel to master the usage method within 1 hour, greatly reducing the requirements for operators' skill levels.

Strong portability: The lightweight body can meet the needs of special working scenarios such as high-altitude welding, making the operation more flexible.

Customized services: Supporting one-to-one customization, able to provide exclusive solutions according to customers' specific needs, and offering full-process technical services.

Wide Application, Assisting the Development of Multiple Industries

With excellent performance, MeiHan series pipe-pipe welding machines have been widely used in many industries, including food fermentation, biopharmaceuticals, water treatment, petrochemicals, instrumentation, automobile manufacturing, pipeline installation, etc., bringing great convenience to pipeline welding and installation work in various industries and winning unanimous praise from customers.

Shanghai MeiHan Intelligent Technology Co., Ltd., as a national high-tech enterprise and ISO9001 certified enterprise with decades of experience, focusing on the research and development and manufacturing of automatic pipe welding equipment, always adheres to the business philosophy of "everything is customer-oriented, customized according to needs, and integrated services are not outsourced", and is committed to building a high-end brand of professional pipe welding equipment. In addition to pipe-pipe welding machines, the company also provides automatic tube-sheet welding equipment, automatic circumferential seam welding machines, hot wire surfacing systems, welding control power supplies and other products and services. If you have relevant needs, please call 18918961606 or visit Shanghai MeiHan's official website (https://www.mwelding.com.cn) for more information.