Industry Pain Points

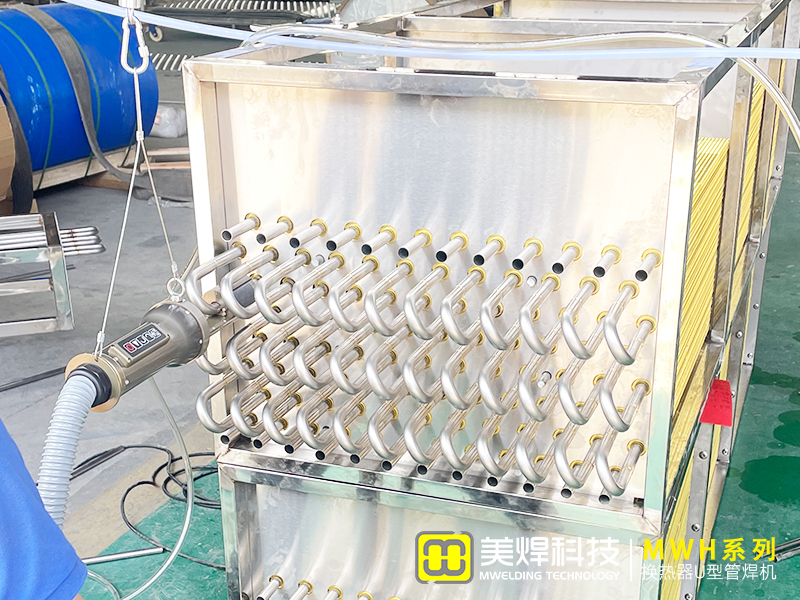

Narrow and poor welding working conditions? Obstructed vision, difficult thermal control and variable welding positions? Welding undercut, deformation and other defects? MWelding's innovative technology has created the MWP Series All-position Tube-to-Tube Sheet Welding Machine, providing comprehensive protection for tube-to-tube sheet welding!MWP Series Models

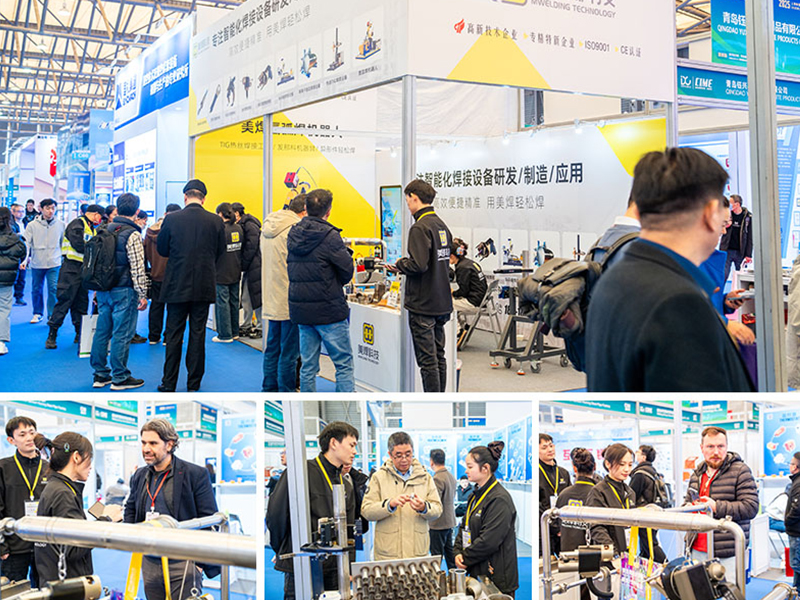

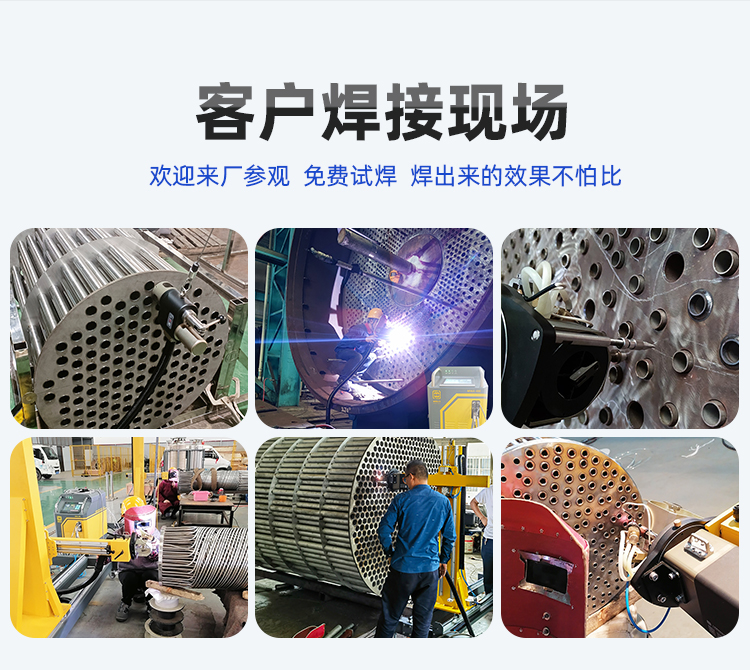

Expert in Welding, Flawless in Seams; Technology for the Nation, Boundless in Innovation

Independent of the traditional "master welder's experience" in welding,

Achieve arc length tracking welding technology,

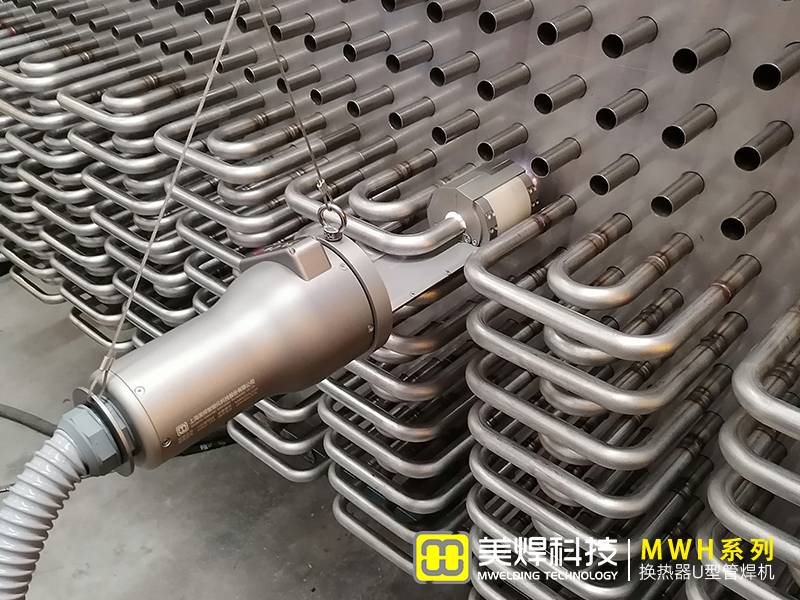

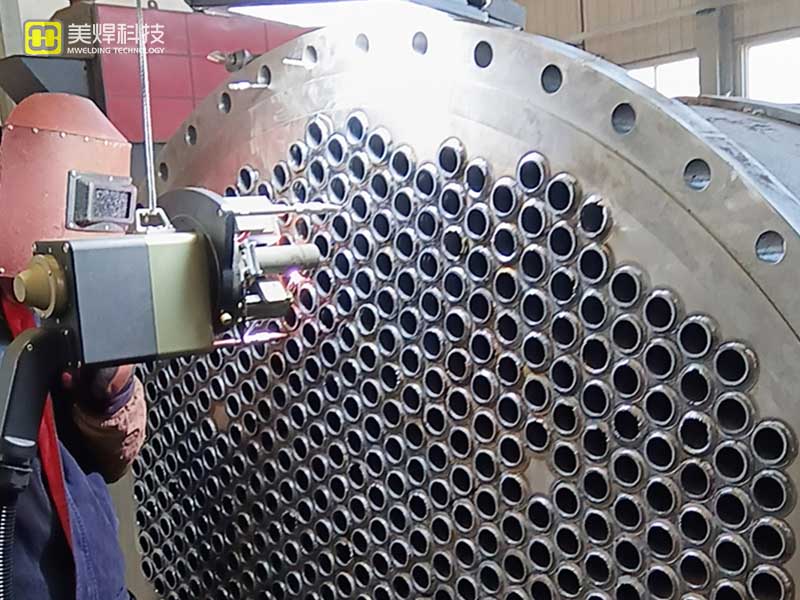

Whether it is the high standards of nuclear power tube-to-tube sheet welding,

Or the dense and complex honeycomb hole welds of heat exchangers,

Let every weld mark be the signature of MWelding!

Performance Features

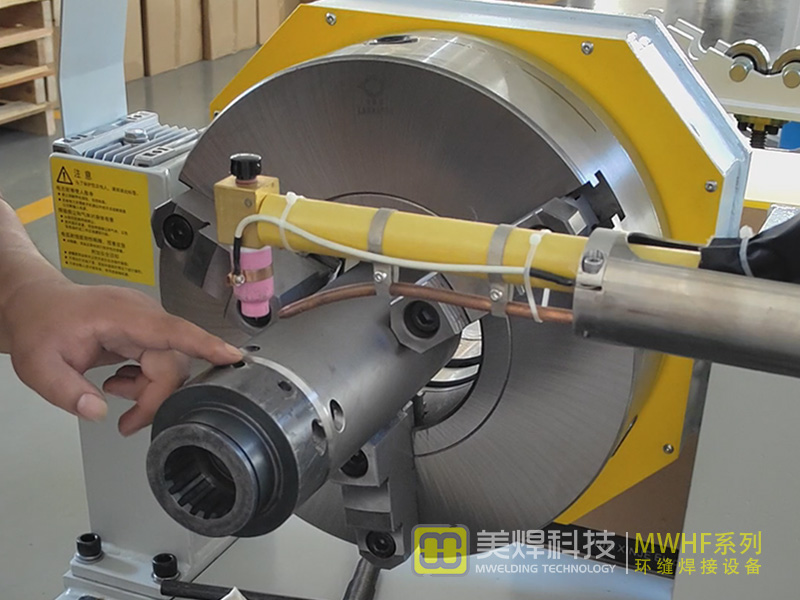

01. Equipped with automatic arc length adjustment function, suitable for welding various pipe fittings, reducing manual intervention and easy to operate;

02. The MWP-38 welding torch head adopts a closed protective cover structure with TIG autogenous welding process, making the welding process purer with excellent gas protection;

03. MWP-65C is a rack-type tube-to-tube sheet welder, more suitable for small-diameter pipe welding, with a minimum pipe inner hole of 6mm;

04. The welding torch adopts circulating water cooling with a high duty cycle, ensuring stable and reliable operation without overheating for long-term continuous work;

05. Under the same working conditions, for different pipe diameters, only need to input the pipe diameter size without re-adjusting the welding parameters for welding;

06. The welding torch is fixed by an internal expanding pneumatic expanding core, and different expanding cores can be replaced according to the inner diameter of the pipe fittings, which is convenient and reliable.

MWelding has been engaged in the R&D and manufacturing of intelligent welding equipment for decades, with its products widely applied in the market. The MWP Series All-position Tube-to-Tube Sheet Welding Machine is designed in accordance with German production standards, with imported core components and raw materials, featuring stable performance, high cost performance and low failure rate. The full-automatic digital intelligent welding control system is equipped with an automatic arc length adjustment function, which can meet the welding requirements of different tube-to-tube sheet types, reduce manual intervention and facilitate operation. On the premise of ensuring excellent and stable internal and external welding quality of products, it greatly reduces the requirements for manual welding skills and cuts down production costs. It is a safe, reliable, economical, portable and high-efficiency tube-to-tube sheet welding machine.

For more products and services such as automatic tube-to-tube welding machines, automatic tube-to-tube sheet welding machines, special automatic circumferential welding machines, hot wire surfacing systems, TIG welding robots, please call: +86 18918961606 or visit the official website of "Shanghai MWelding": https://www.mwelding.com.cn/ , as well as our WeChat Official Account and Video Account.