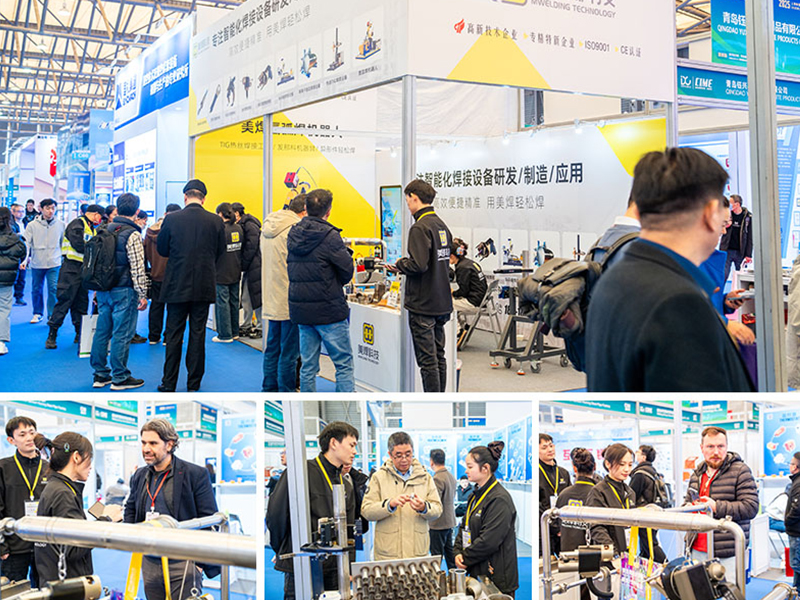

On December 11, 2025, the 4th Asia Metal Building Design and Industry Expo (MBE 2025) grandly opened at the Shanghai New International Expo Center. As an annual flagship event in the metal building sector, this expo brought together over 600 enterprises from 35 countries and regions, attracting global professional audiences to focus on the new trends of green and intelligent construction. Shanghai Mwelding Technology made a high-profile appearance with its full range of intelligent welding solutions in the exhibition area of Shanghai Welding Association, emerging as a core focus of the expo thanks to its precise and efficient technical advantages and product matrix tailored to industry needs.

Core Products

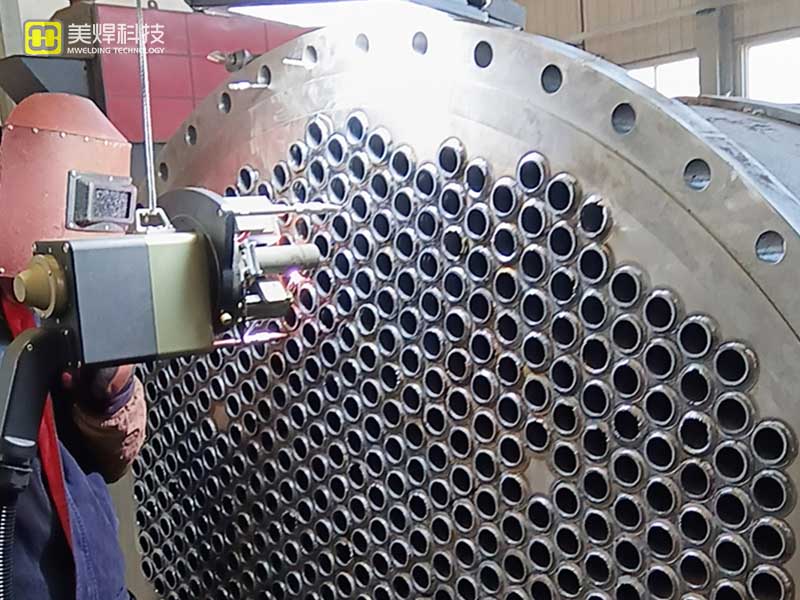

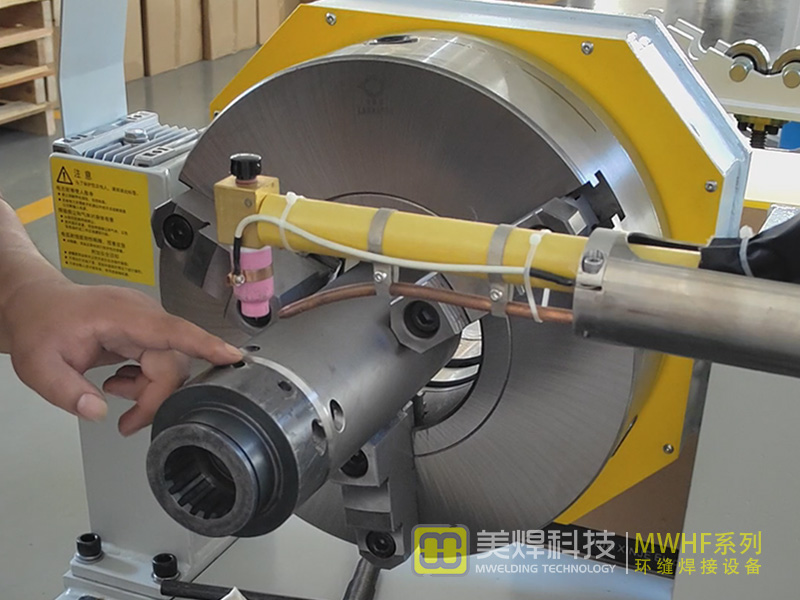

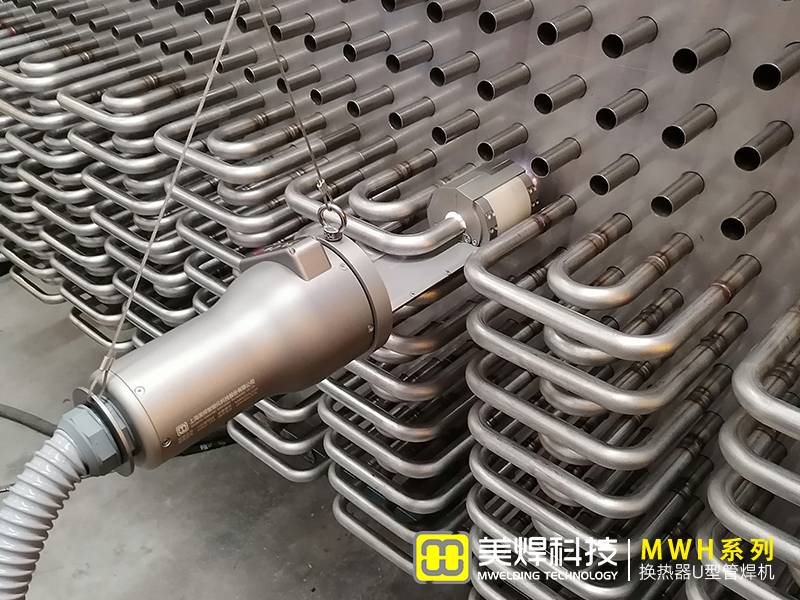

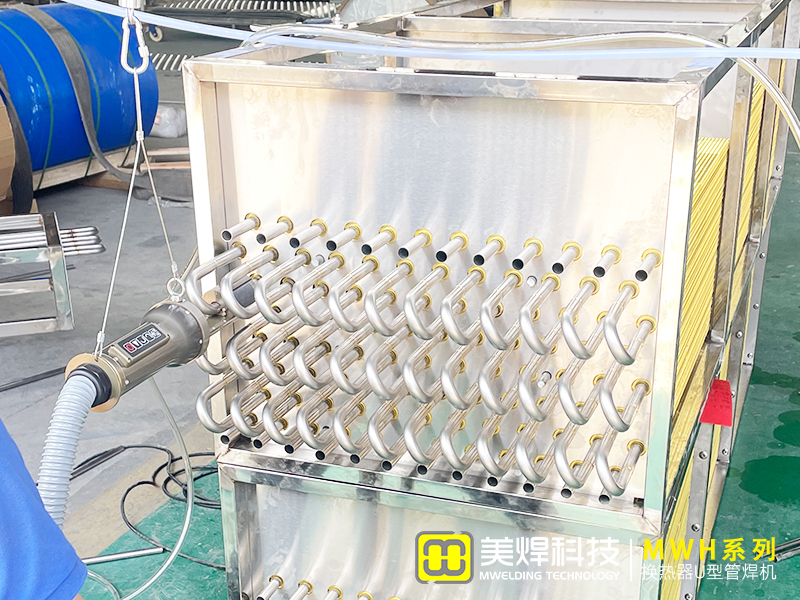

Mwelding Technology showcased nine core product systems at its booth, including heat exchanger U-tube welding machines, closed-type pipe-to-pipe welding machines, open-type pipe-to-pipe welding machines, all-position tube-sheet welding machines, automatic girth welding equipment, automatic longitudinal seam welding equipment, plasma welding equipment, hot wire TIG surfacing welding equipment, and argon arc welding robots. These products fully cover the welding needs of stainless steel pipes, carbon steel pipes, and other pipes with various diameters and wall thicknesses.

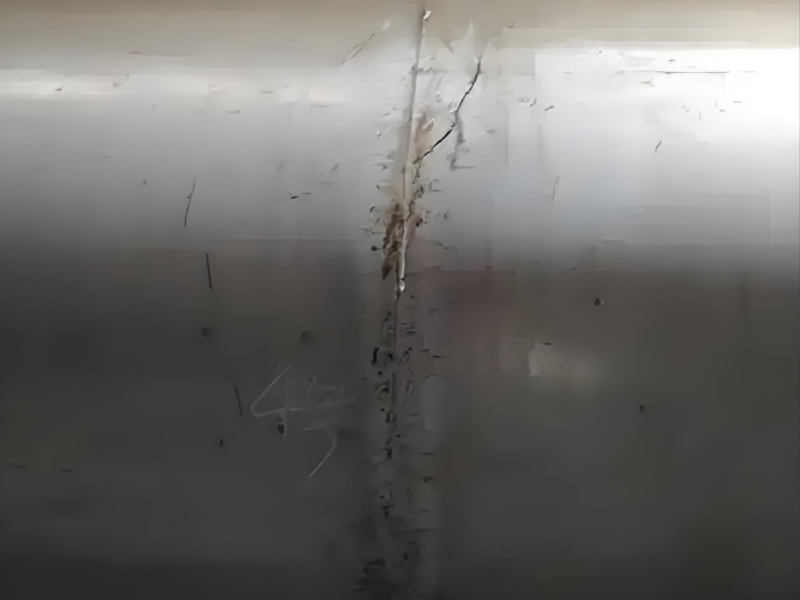

Among them, the "twin pillar combination" of MWF series closed-type pipe-to-pipe welding machines and MWG series open-type pipe-to-pipe welding machines garnered the most attention. The closed-type pipe-to-pipe welding machine is capable of welding thin-walled stainless steel and carbon steel pipes below 3.5mm, and its button-operated design enables personnel with zero foundation to master operation within 1 hour in narrow working spaces at construction sites, significantly reducing the training costs of construction teams. The MWG series open-type pipe-to-pipe welding machine is developed for welding medium and thick-walled steel structure pipes; through welding speed measurement feedback and automatic arc length adjustment technology, it ensures weld formation meets flaw detection requirements of Grade II or above, providing reliable guarantee for welding metal building pipe nodes.

Interactive Experience: Scenario-based Presentation of Intelligent Welding

During the expo, Mwelding Technology's "Customized Solutions Consulting Area" was always bustling with visitors. For the personalized needs of different enterprises, the technical team provided on-site full-process solutions covering equipment selection, process optimization, and personnel training.

Intelligent Upgrading and Industrial Integration of the Welding Industry

As a national high-tech enterprise and a Shanghai Specialized, Sophisticated, Unique and Novel Enterprise with 13 years of deep engagement in the automated welding field, Mwelding Technology not only demonstrated its product strength at this expo but also conveyed its development philosophy of "driving industry upgrading through technological innovation". Based on its technical accumulation in serving high-end fields such as nuclear power, aerospace, semiconductors, food and pharmaceuticals, water treatment, and machinery manufacturing, it proposed a full-chain solution of "intelligent welding - cost reduction & efficiency improvement - safety assurance", which was highly recognized by experts from the Shanghai Welding Industry Association.

According to Ms. Tang, Sales Manager of Mwelding Technology, multiple intentional cooperation agreements were reached on the first day of the expo, with purchasers from Russia, India, and other regions flocking to Mwelding Technology's booth. "The MBE Expo has built a bridge for us to connect with the global market. In the future, we will continue to focus on the needs of the metal building industry, develop robotic argon arc welding technology and collaborative robot welding technology, and provide stronger technical support for green and intelligent construction."

Guided by MBE2025's core concept of "whole industrial chain integration", Mwelding Technology, with intelligent welding technology as the link, is continuously promoting the transformation of the metal building industry from "traditional construction" to "intelligent manufacturing". As a national high-tech enterprise and an ISO9001 & CE certified enterprise, Mwelding not only supplies welding machines but also customizes welding equipment according to manufacturers' special needs, offering free sampling and free test welding. To learn more about intelligent welding equipment, please call Mwelding's technical hotline at 18918961606 immediately or visit Mwelding's official website (https://www.mwelding.com.cn).