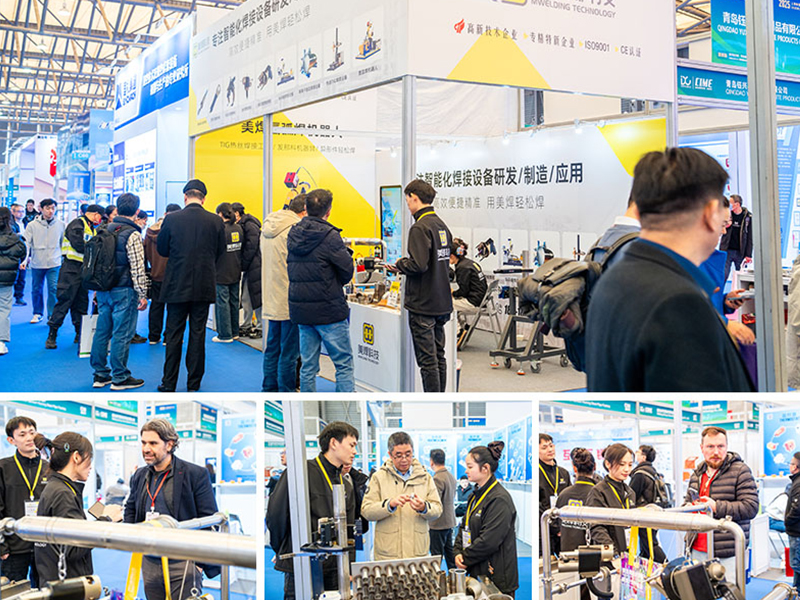

As the dual carbon goals coincide with the explosive growth of the digital economy, liquid cooling technology has emerged as a core solution for data centers to reduce costs, enhance efficiency and achieve green energy conservation, becoming an inevitable choice for industry upgrading. From December 17 to 19, 2025, the 5th Shanghai International Data Center Liquid Cooling Technology Exhibition (CIME 2025) grandly kicked off at the Shanghai New International Expo Center, gathering top enterprises and cutting-edge technologies in the global liquid cooling sector. As a national high-tech enterprise and a Shanghai specialized, refined, featured and innovative enterprise in the intelligent welding field, Mwelding made a stunning appearance at Booth C66, Hall W4 with its nine core product matrices, under the theme of "Empowering New Paths of Liquid Cooling Heat Dissipation with Intelligent Welding", to explore industrial opportunities and discuss technological innovation with industry peers!

Backed by Specialized, Refined, Featured and Innovative Strength, Core Exhibits Attract Wide Attention

Having been deeply engaged in the intelligent welding field for more than a decade, Mwelding has always taken technological innovation as its core driving force. For this exhibition, the company meticulously prepared core intelligent welding equipment achievements covering the entire manufacturing process of liquid cooling equipment. At the exhibition site, nine series of products including the Heat Exchanger U-bend Tube Welding Machine, Closed Pipe-to-Pipe Welding Machine, Open Pipe-to-Pipe Welding Machine, All-position Tube-sheet Welding Equipment and TIG Welding Robot were displayed collectively, becoming the focus of the booth with their precise and efficient technical advantages.

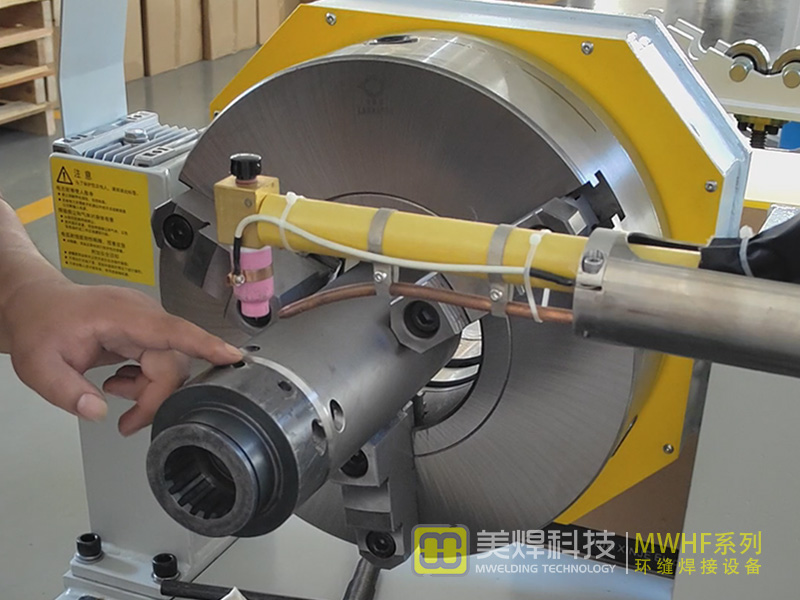

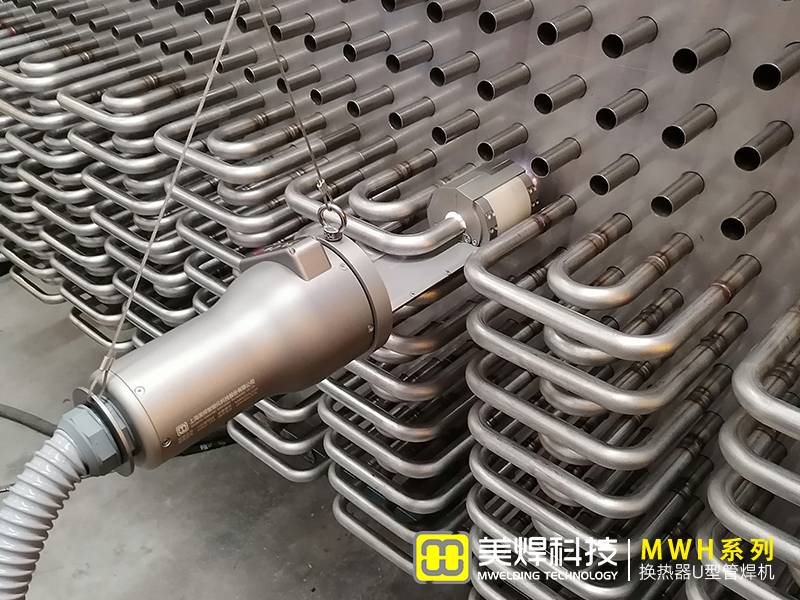

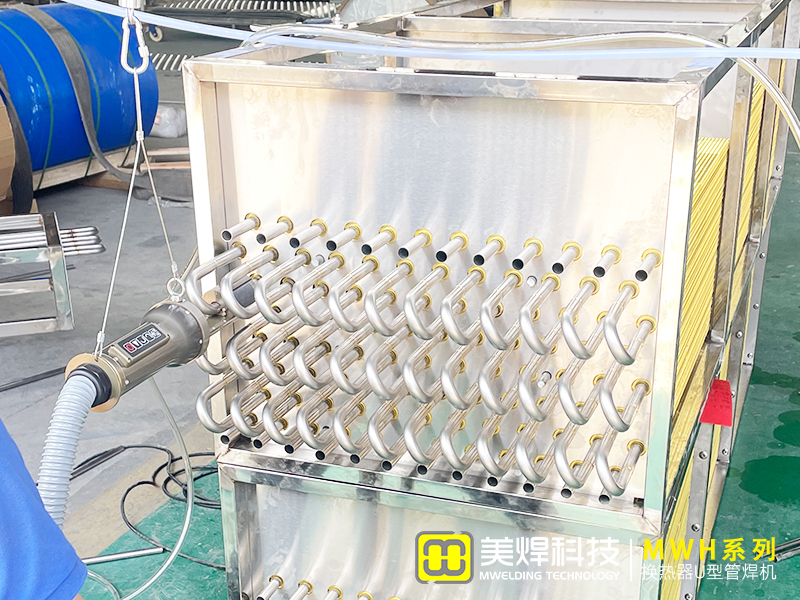

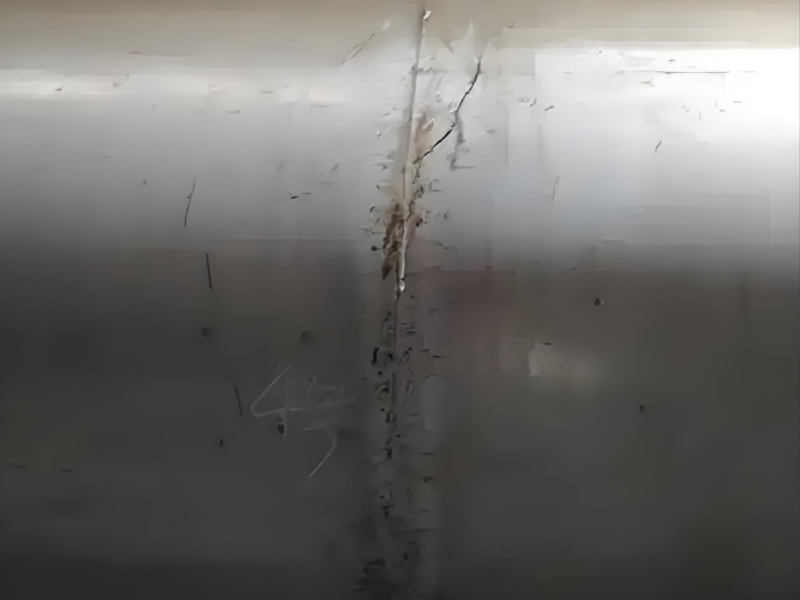

Among them, the MWH series heat exchanger U-bend tube welding machine can be called an "efficiency tool" for liquid cooling equipment manufacturing, specially designed to solve the industry pain points in U-bend tube welding of liquid cooling heat exchangers/radiators. The closed pipe-to-pipe welding machine is mainly used in various industries such as food and medicine, refrigeration, biology, fluid, clean pipeline, aerospace, semiconductor and pipeline installation. It adopts TIG autogenous welding method, with water-cooled circulation protection for the machine body, ensuring no overheating during long-time operation. The welding torch is light in weight and features one-key operation, making it easy to learn and use. For pipes made of medium and thick-walled stainless steel, carbon steel, titanium alloy and other materials, the open pipe-to-pipe welding machine can greatly improve production efficiency while ensuring welding stability.

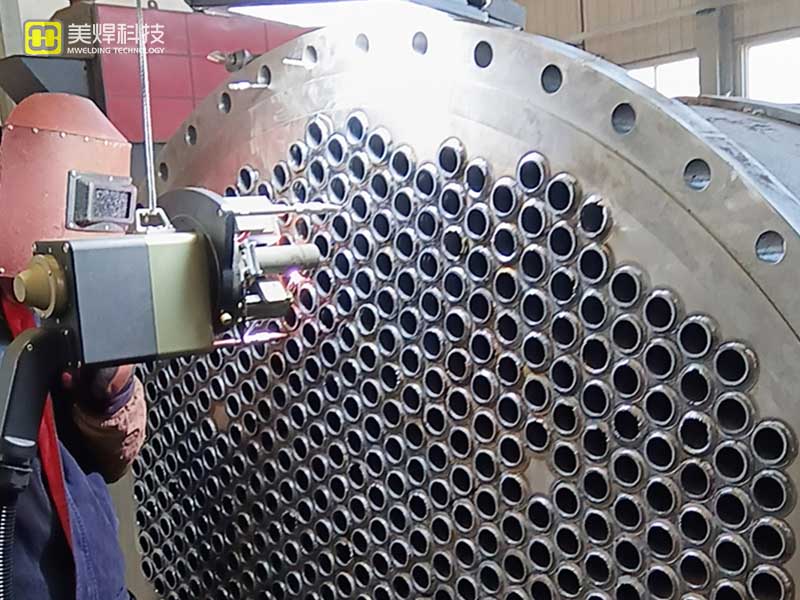

In addition, Mwelding's all-position tube-sheet welding equipment can easily handle the tricky dense tube-sheet holes. This equipment adopts a one-key operated pneumatic expanding core structure, suitable for various welding forms such as tube protrusion, tube flush and tube retraction. Audience at the site stopped to watch the equipment operation demonstration one after another, and spoke highly of the precision and efficiency of this tube-sheet welding equipment.

Professional Technical Team on-site for Accurate Matching, Jointly Building a Green Computing Power Future

During the exhibition, Mwelding set up a professional technical expert team to be on-site throughout the event, providing one-on-one technical consultation, customized solution design and equipment operation demonstration services for the audience visiting the booth, accurately meeting the core needs of liquid cooling equipment manufacturers in improving welding efficiency and quality. Whether it is technical problems in narrow space operation or the demand for mixed production of multi-model pipe diameters, the expert team can provide targeted solutions based on rich industry experience, and reached a number of intentional cooperation agreements on-site.

This appearance at the 2025 Shanghai Liquid Cooling Exhibition is not only a concentrated display of Mwelding's intelligent welding technology strength, but also an important opportunity for the company to deeply integrate into the liquid cooling industrial ecosystem and help the development of green computing power. Mwelding will continue to take technological iteration as the engine, deepen its roots in the intelligent welding field, unite industry partners to jointly promote the standardization and large-scale development of the liquid cooling industry, and inject strong impetus into the "Eastern Data and Western Computing" project and the construction of green computing power.