In the field of welding, orbital welding is highly favored for its high welding quality, among which TIG welding is particularly common. This process uses a mechanical system to guide the welding torch to rotate around the workpiece, achieving precise and efficient welding operations. Industries such as aerospace, high-speed railways, nuclear power, pharmaceuticals, food, microelectronics and semiconductors, electric power, petroleum, and natural gas all rely on orbital welding technology.

Orbital welding mainly covers two applications: pipe-to-pipe welding / pipeline welding, and pipe-to-tubesheet welding:

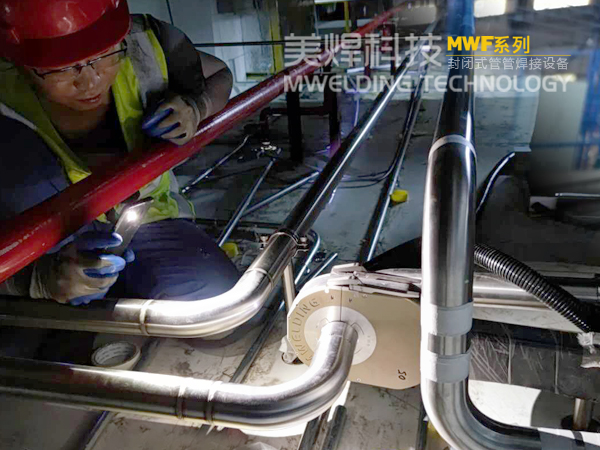

Pipe-to-pipe welding applications include pipe-to-pipe butt joint, welding of pipe fittings with flanges, elbows, T-joints, and valves.

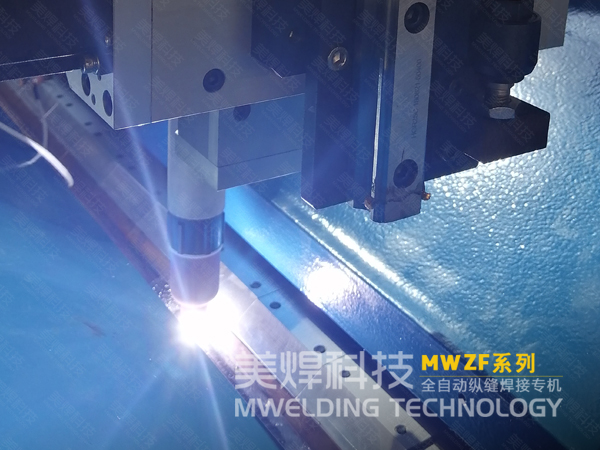

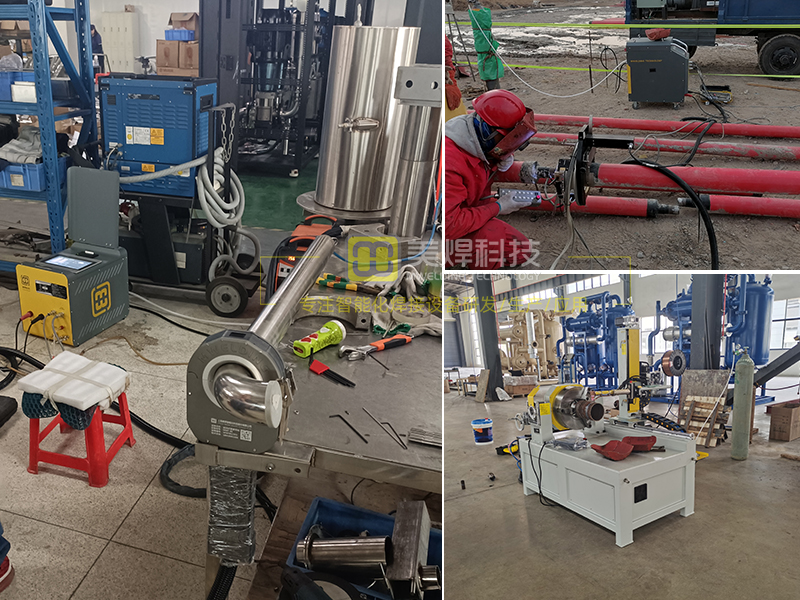

MWELDING Technology mainly provides three types of standard TIG pipe-to-pipe welding machines:

Enclosed autogenous pipe welding machine (MWF Series), which can weld pipes with outer diameter from 1.6mm to 170mm, suitable for thin-walled pipes with wall thickness ≤3.5mm.

Open wire-filled pipe welding machine (MWG Series), which can weld pipes with outer diameter from 8mm to 325mm, suitable for medium and thick-walled pipes with wall thickness of 1-30mm.

Orbital welding carriage (MWHF Series), which can weld pipes with outer diameter above 50mm. Depending on the equipped welding torch, the maximum pipe diameter that can be welded is 500mm.

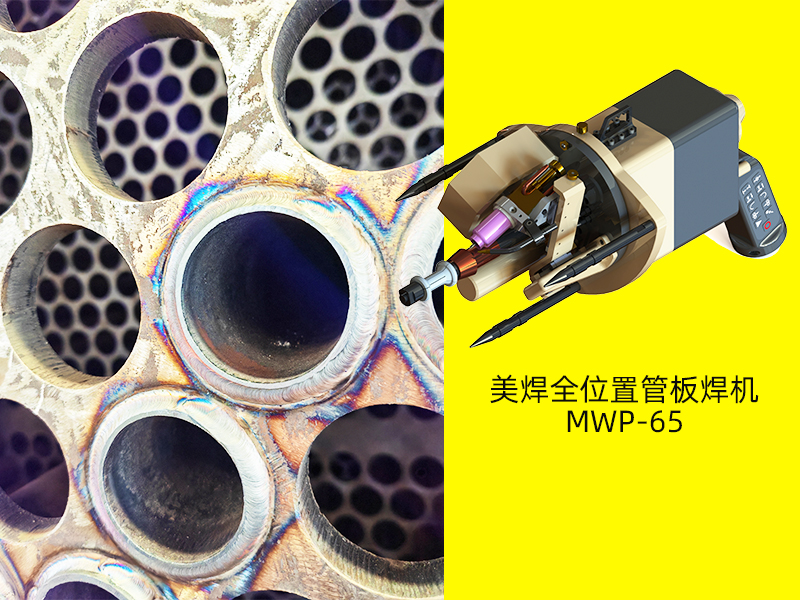

Pipe-to-tubesheet welding is mainly used in the production of boilers and heat exchangers

MWELDING Technology provides the following types of TIG tube-to-tubesheet welding machines:

Enclosed flush tubesheet welding machine (MWP-38), which can weld pipes with diameter from 10mm to 38.1mm, with joint forms: flush, inner shrinkage (maximum 1mm), outer extension (maximum 0.5mm);

Open type tubesheet welding machine for internal bore welding (MWP-65), which can weld pipes with inner diameter from 6mm to 63mm, with joint forms: flush, inner shrinkage (maximum 2mm), outer extension (maximum 13mm), internal bore;

Flashlight type heat exchanger U-tube welding machine (MWH Series), featuring enclosed torch design, circulating water cooling mode, high duty cycle, capable of welding pipes with diameter 12.7mm-25mm, with automated and intelligent welding, improving production efficiency for dense U-tube welding.

Working Principle of TIG (GTAW) Automatic Tungsten Inert Gas Welding

TIG (Gas Tungsten Arc Welding, GTAW for short) welding is an arc welding method that uses a non-consumable tungsten electrode and inert gas protection. During TIG welding, a stable arc is generated between the non-consumable tungsten electrode and the workpiece. This arc is supported by the electrode and serves as a heat source, causing the workpiece metal to heat and melt, thereby forming a molten pool.

To ensure welding quality, it is necessary to maintain the workpiece molten pool and tungsten electrode in an oxygen-free environment. This is usually achieved by using an inert gas (such as argon) as the shielding gas, which can effectively isolate oxygen in the air and prevent the molten pool and tungsten electrode from being oxidized.

If additional filler metal is required for the welding operation, the welding wire can be fed into the welding area manually or by means of an external wire feeding device. Under the high temperature generated by the arc, the welding wire melts rapidly and mixes with the workpiece metal to form a weld joint together.

Advantages of TIG (GTAW) Automatic Tungsten Inert Gas Welding

It can weld almost all materials, including stainless steel, carbon steel, nickel-based alloys, aluminum, copper, titanium, zirconium and their alloys, etc. Under specific conditions, even brass and bronze can be welded; if the wire-adding method is adopted, dissimilar steels can also be welded.

It can realize all-position welding; the process is stable and reliable, and welding defects can be controlled within 1%; no welding slag or fume is generated during the welding process; the arc voltage that directly affects the arc length and various types of current intensity can be automatically controlled by programming; wire-added or wire-free welding can be realized.