In the modern industrial manufacturing landscape, surfacing welding technology, as a key process to enhance workpiece surface performance, is widely applied in high-end manufacturing fields such as aerospace, energy equipment, and construction machinery. Addressing the high-precision surfacing needs for complex workpieces, the Hot-Wire TIG Surfacing Welding System developed by Shanghai MeiHan Intelligent Equipment Co., Ltd. emerges as an ideal solution for tackling surfacing challenges on complex structures like channels, end faces, outer circles, and intersecting lines, thanks to its advanced technical architecture, precise process control, and reliable equipment configuration.

System Design: A Flexible Architecture for Diverse Working Conditions

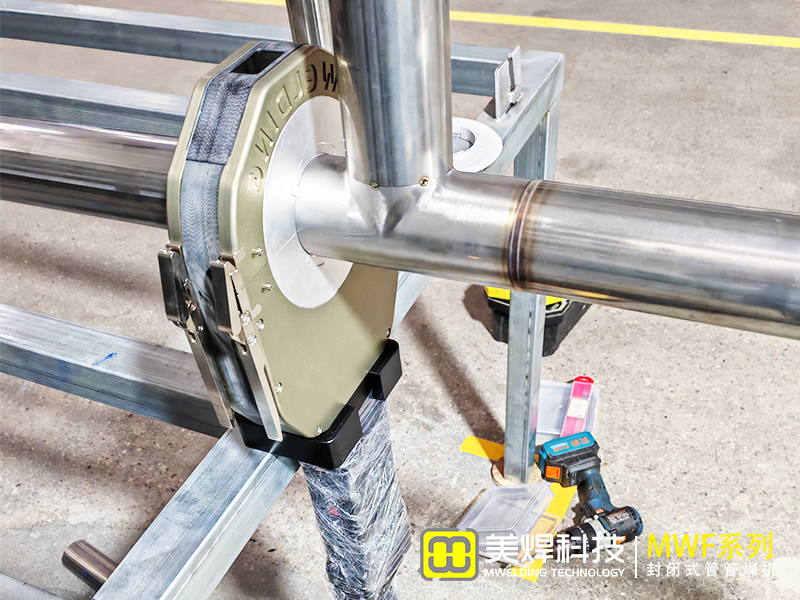

The system adopts a core architecture of "positioner + manipulator," creating a highly flexible welding platform. The workpiece is fixed on the AR5T welding turntable via a four-jaw chuck, capable of handling inner/outer circle workpieces with diameters ranging from 35mm to 1500mm and depths ≤1000mm, supporting a maximum load of 5000kg. The ACB2020S high-precision manipulator features a 2000mm vertical lifting stroke and a 1600mm horizontal telescoping stroke. Equipped with a servo-driven precise swing mechanism, it enables accurate adjustment of the welding torch angle, efficiently addressing surfacing requirements for complex profiles such as channels, trapezoidal grooves, and intersecting lines. The collaborative control mode of "workpiece rotation + torch linear motion" ensures welding trajectory accuracy, while freely switchable step/continuous motion modes adapt to different weld forming requirements.

Core Configuration: Building Blocks for Precise Welding

The system integrates Panasonic YC-400TX4HG5 TIG welding power source and YC-400TX4HGK hot-wire power source, forming a high-efficiency and stable energy supply system. Both power sources adopt IGBT inverter technology, offering a wide current adjustment range (4-400A) and pulse frequency adjustment (0.5-500Hz). They can achieve full-position welding for medium-thick plates using low-frequency pulses and delicate surfacing for heat-sensitive materials with high-arc stiffness from medium-frequency pulses. The supporting digital high-speed wire feeder (wire feeding speed: 400-8000mm/min) and hot-wire feeding bracket system ensure precise delivery of φ1.2mm welding wires. Combined with a water-cooled torch set (including 25mm, 50mm diameter and outer-circle special torches), it provides full-scenario coverage for different workpiece sizes.

Process Advantages: Breaking Through Traditional Surfacing Limitations

In terms of process control, the system realizes full-process digital management through the ESY-HTIG special surfacing control software. This software supports multi-axis control and can pre-set welding programs for 12 typical workpieces such as spherical inner walls, ring groove surfaces, and half-moon plates, allowing independent adjustment of over 30 process parameters including welding current, rotation speed, and wire feeding parameters. Its core advantages include: Precise control of single-layer weld thickness (≤3mm) and dilution rate (<10%), meeting stringent purity requirements for cladding layers in aerospace components; Solving fusion challenges for dissimilar materials through automatic arc length control and adjustable dwell time at swing edges; Supporting continuous welding of 4 through-holes and real-time parameter fine-tuning via a wired controller, enabling intelligent integration from programming to welding.In practical applications, for base materials like 4130 steel and F51 duplex steel, the system stably surfaces materials such as ERNiCrMo-3 nickel-based alloy and Stellite cobalt-based alloy, with a cladding hardness uniformity error ≤5% and surface roughness Ra≤3.2μm.

Quality Assurance: A Full-Cycle Service Commitment

To ensure long-term stable operation, the system is equipped with power units featuring a three-layer, four-chamber dust-proof structure (IP23 protection level) and a CW5300 constant-temperature cooling water tank, adapting to harsh industrial environments with high temperatures and dust. The supplier provides a full-cycle service including "installation & debugging - personnel training - lifelong maintenance": professional engineers conduct on-site equipment calibration to ensure operators master core skills such as programming, debugging, and fault diagnosis; free component replacement is offered during the one-year warranty period, and a 24-hour response to maintenance needs is guaranteed after the warranty. This dual of hardware reliability and service system equipment overall utilization to over 98%, significantly reducing customer downtime costs.

The launch of the Hot-Wire TIG Surfacing Welding System marks a new stage in complex-profile surfacing, entering an era of "precise control + intelligent production." Its interdisciplinary design integrating mechanical engineering, welding power supply, and digital control not only meets current high-precision surfacing requirements in advanced manufacturing but also lays a technical foundation for future welding applications of new materials and structures through modular configuration and process scalability. With the deepening of industrial intelligence, this system is set to play a more significant role in critical fields such as aero-engine blade repair and nuclear valve sealing surface surfacing, driving the transformation of high-end equipment manufacturing from "manufacturing" to "intelligent manufacturing."