In many manufacturing processes, annular welds such as those on pipe fittings and flanges are quite common. The Mwelding intelligent circumferential seam welding special machine, as a widely used welding device, offers low - threshold operation and high - quality welding output, bringing a great deal of convenience to actual production and processing.

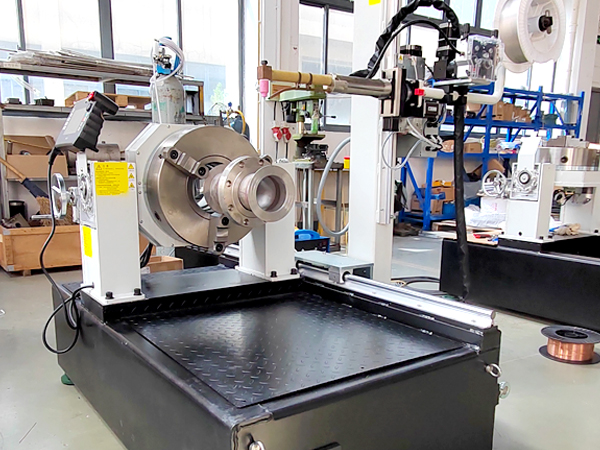

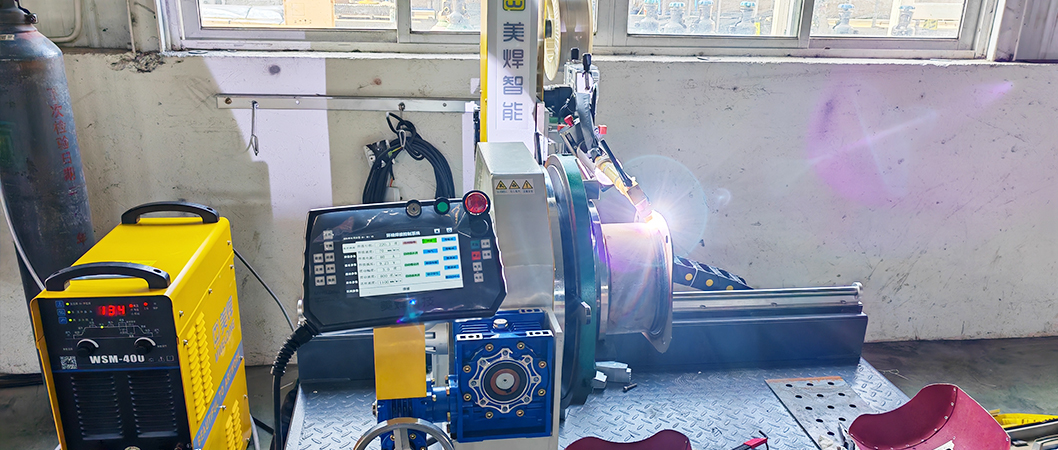

According to the different sizes of pipe fittings and welding processing requirements, the structures of circumferential seam automatic welding machines vary widely. There are vertical circumferential seam automatic welding machines, horizontal circumferential seam automatic welding machines, side - beam - type circumferential seam automatic welding machines, etc. Generally, such equipment is large in size, heavy - duty, and requires a certain amount of floor space. In practical applications, for customers mainly dealing with short and small pipe fittings, the compact mini pendulum - type circumferential seam welding machine is more suitable.

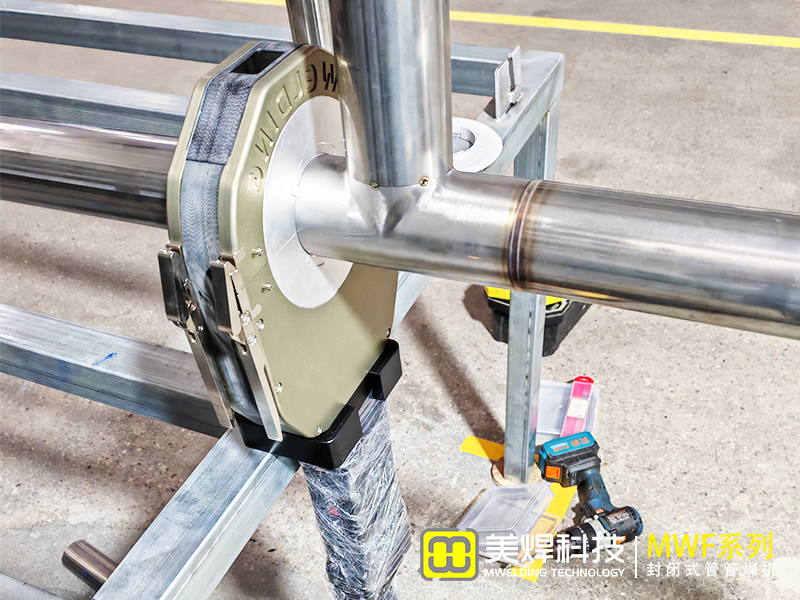

The Mwelding mini pendulum - type circumferential seam automatic welding machine is a compact circumferential seam welding machine with a small and mini - sized design and flexible operation. Equipped with a pendulum - type welding torch structure, it can reach deeper into the interior of pipe fittings or small parts, enabling more detailed and flexible welding, with stronger flexibility and adaptability.

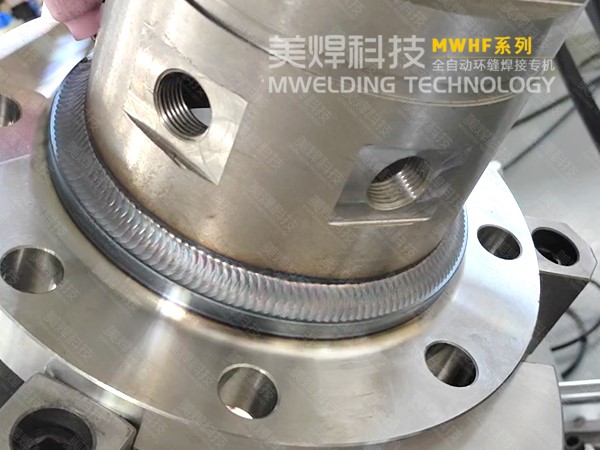

The mini MWHF series circumferential seam welding equipment, while retaining the basic functions of a circumferential seam welding machine, has a reasonable layout and a compact and optimized design, effectively reducing its volume. It has a small overall shape, takes up little space, and is suitable for TIG welding. It can be used for circumferential seam welding of pipe fittings made of various materials such as carbon steel, stainless steel, alloys, aluminum alloys, and nickel - based alloys.

It can be used for butt - jointing and inserting of pipe - to - pipe, pipe tees, pipe elbows, pipe flanges, etc. The full - angle positioner, combined with the welding torch sliding and adjustment mechanism, can accurately meet the multi - angle positioning requirements of welded workpieces. The equipment configuration and process can be selected and adjusted according to requirements, with stronger economy, adaptability, and compatibility. The welding control function is detailed and comprehensive, supporting speed control, current control, wire feeding control, rotation control, gas shielding time control, and automatic arc length control, etc. The complete welding feed system, wire feeding system, oil circuit system, and cooling system ensure the long - term stable operation of the equipment.

Compared with traditional operations, this mini - circumferential seam welding machine inherits the advantages of circumferential seam welding equipment. It has incomparable advantages in welding efficiency, quality assurance, welding uniformity, and intelligent digital management. The increase in the first - pass qualification rate, the uniform output of weld seams, the enhanced controllability of the welding production process, and the improvement of the production operation environment have effectively promoted the improvement of production capacity. More and more enterprises are unlocking more production potential through such transformations.

When purchasing equipment from manufacturers, enterprises can start from the actual situation of their own production line equipment and welding requirements, seek quotations from multiple manufacturers and compare solutions. By referring to the application examples of the manufacturers' welding equipment, they can implement the application details of the equipment and customize production. Combining the characteristics of the industry and enterprise welding operations with the existing equipment production line, they can meet the welding requirements of manufacturing and processing by adding, reducing, or expanding the functions of the welding system. At the same time, according to the requirements of the production process, the equipment modules can be flexibly adjusted to ensure welding quality while improving production efficiency. Moreover, after the equipment is purchased, it can be put into production immediately, closely integrated with all production links, with quick results and convenient maintenance and management in the later stage.

Mwelding Technology has been rooted in the pipe welding field for decades. With leading technology, precision manufacturing, and excellent services, it has served numerous customers. Its in - house technical support team, with innovative technical strength and long - term market application experience, provides one - to - one customized welding services, full - process welding operation guidance, rapid after - sales service response, welding system optimization and upgrading, regular product maintenance, and preferential value - added services such as automation equipment leasing according to customer requirements. Starting from the customer's perspective, it deeply participates in the upper, middle, and lower segments of the business process, acting as a professional supporter of welding technical services to tap and create new value for customers.

Mwelding Technology's pipe welding equipment products and services have withstood the test of the market for decades and have received unanimous praise from customers! The satisfaction of our customers is the greatest support for us! Mwelding thanks you for your trust and is committed to serving you wholeheartedly!

For more products and services such as automated pipe - to - pipe welding machines, automated pipe - to - plate welding machines, automated circumferential seam welding special machines, and hot - wire surfacing systems, please call: 189 - 189 - 61606 or visit the official website of "Mwelding Technology": https://www.shmeihan.com, WeChat official account, and Video Channel for more information.