In the field of industrial manufacturing, tube-sheet welding serves as a core process for key equipment such as pressure vessels, heat exchangers, and boilers. Its quality and efficiency directly impact product reliability and enterprise competitiveness. The MWP series all-position tube-sheet welding machines independently developed by Shanghai MeiHan Intelligent Technology Co., Ltd. have become a highly regarded automated welding solution in the industry, thanks to their German production standards, intelligent control systems, and remarkable cost-saving and efficiency-improving capabilities.

I. Technological Innovation: Intelligence Drives Welding Revolution

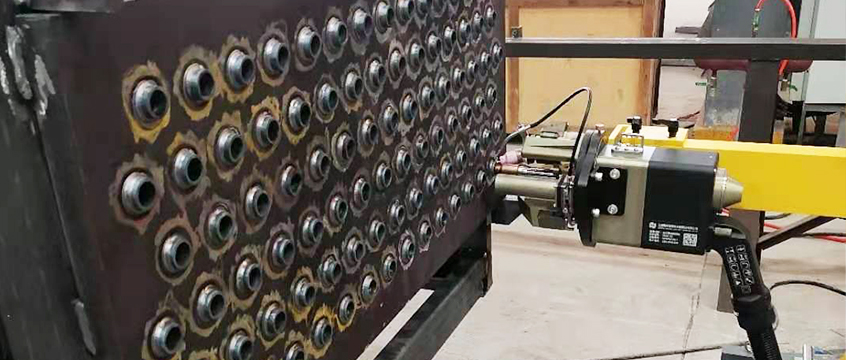

The core advantage of MeiHan tube-sheet welding machines lies in the deep application of the digital intelligent welding system. Equipped with a fully automatic digital control system, the equipment dynamically adjusts welding speed and energy output by real-time collecting 12 parameters such as arc voltage and current, achieving precise control of the welding process. For example, facing different pipe diameters (Φ12-114mm) and welding forms (pipe extension, pipe flush), the system can automatically match over 200 parameter models in the expert database, completing standardized welding without manual intervention. This technological breakthrough has fundamentally changed the traditional manual welding that relies on technicians' experience—ordinary workers can operate after simple training, significantly reducing enterprises' dependence on highly skilled talents.

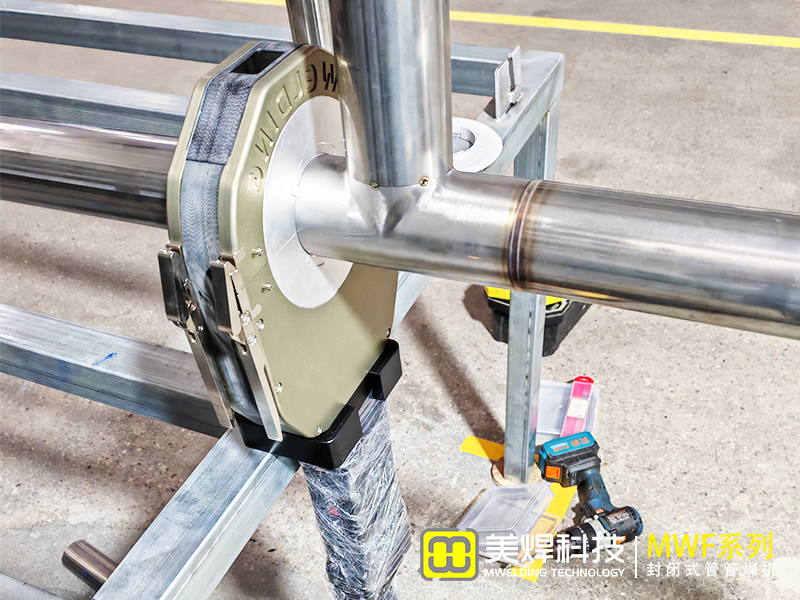

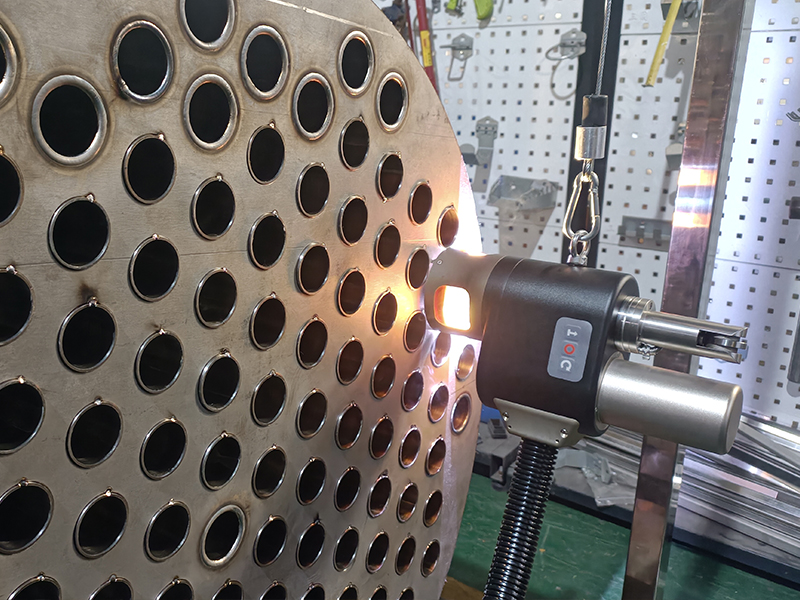

In hardware design, MeiHan tube-sheet welding machines adopt a modular structure and imported German core components to ensure stability and durability. For instance, the full-body circulating water cooling system supports 2,000 consecutive welds without shutdown, increasing the duty cycle by over 30%; the pneumatic elastic expansion core fixture achieves a positioning accuracy of ±0.05mm, combined with a rotation-free winding welding method to complete 360° all-position welding. Additionally, the built-in wire feeder supports a 1KG wire reel, and the water-electricity-gas pipelines adopt internal transmission design to avoid external winding interference, further improving operational convenience.

II. Efficiency Revolution: Data Witnesses Cost Reduction and Efficiency Improvement

The practical application effects of MeiHan tube-sheet welding machines have been verified by numerous customer cases. Take a leading refrigeration equipment enterprise as an example: after adopting the MWP-65 model, the annual comprehensive cost per unit was reduced by 1.12 million RMB, with an investment payback period of only 7 months. The specific performance includes:

Capacity Leap: Daily production capacity per unit increased from 2,000 roots by manual welding to 6,000 roots, tripling efficiency, and only requiring 2 general workers for management;

Quality Optimization: The first-pass qualification rate of welds reaches over 98%, the non-destructive testing grade meets Class II standards, and the export product claim rate dropped from 5% to 0.3%, directly prompting customers to add 30 million RMB orders;

Manpower Streamlining: 2 units can replace 6 welders, reducing comprehensive labor costs by 60%, while avoiding quality fluctuations caused by manual welding fatigue.

In typical scenarios such as heat exchangers and pressure vessels, the MWP series welding machines demonstrate higher adaptability. For example, a 15mm pipe diameter can be welded in only 20 seconds, with a weld leg height of 6-7mm, supporting autogenous or filler wire welding for various materials such as carbon steel, stainless steel, and titanium alloy. This efficient and stable performance has made it widely used in industries such as energy, petrochemicals, and food pharmaceuticals, becoming the preferred solution for enterprises facing tight schedules and strict quality requirements.

III. Industry Value: Promoting Welding Industry Upgrading

The value of MeiHan tube-sheet welding machines lies not only in single-machine performance but also in their innovation of the entire welding industry chain. Through the digital welding management system, the equipment can upload welding parameters to the MES system in real time, achieving full-process traceability and quality early warning of production data, with a response time shortened to 15 seconds. This intelligent management model helps enterprises shift from "experience-driven" to "data-driven", significantly improving production transparency and decision-making efficiency.

As a national high-tech enterprise, MeiHan Technology has always adhered to the service concept of customization based on needs, providing personalized solutions for different industry requirements. For example, a mini portable model (weighing only 9KG) designed for narrow-space operations can enter the interior of Φ9.52mm pipelines to complete welding; the 3D dynamic compensation technology developed for high-precision scenarios can automatically compensate for pipe processing errors of ±0.15mm, ensuring weld uniformity. This technical flexibility has also enabled it to occupy a place in high-end fields such as aerospace and nuclear power.

IV. Future Outlook: Leading the New Trend of Intelligent Welding

With the advancement of Industry 4.0 and intelligent manufacturing, the intelligence and greenness of welding equipment have become inevitable trends. By integrating technologies such as AI algorithms and the Internet of Things, MeiHan tube-sheet welding machines are upgrading from single welding tools to intelligent welding workstations. For example, the latest MWP-120 model has achieved remote monitoring and cloud analysis of welding parameters, supporting multi-device collaborative operations, providing possibilities for large-scale flexible production.

Against the backdrop of the continuous growth of the global tube-sheet welding robot market (expected to reach $245 million by 2031, with a CAGR of 3.8%), MeiHan Technology is accelerating its expansion into international markets with its technical accumulation and market reputation. Its products not only serve leading enterprises such as Sinopec and China National Nuclear Corporation in China but also export to countries like Russia and Ukraine, becoming a bright business card of "Made in China".