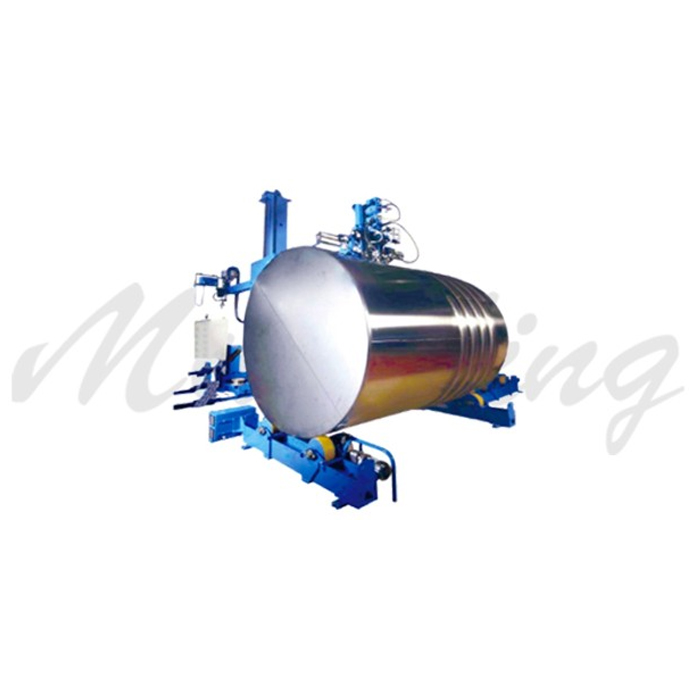

Circumferential Seam Welding Machine MWHF

Product Mode:MWHF

Welding Method:Wire filling welding

Product Features:High degree of automation, personalized customization, and diverse styles

Protection Method:Argon gas and circulating water cooling

Product Introduction

Application industries: boilers, heat exchangers, pressure vessels and other industries.

Applicable standard: stainless steel, carbon steel, titanium alloy, etc.

Applicable pipe wall guide: 1mm-6mm, pipe diameter: φ 89-400 mm;

V-shaped slope (237-45) shall be provided for the platform with a thickness below 6mm, and U-shaped groove shall be provided for the platform with a thickness above 6 mm. 。

Welding forms: pipe welding, pipe head welding, pipe flange welding, etc.;

Shirts and shapes can be customized as required: matching power supply and main control system imported.

Product features:

Reasonable internal structure, flexible operation, high orange motor control and smooth rotation

Equipped with manual arc length tracking fitting, the distance between workpiece and tungsten electrode can be adjusted.

Perfect function of zone division and parameter saving, convenient storage and call for different welding processes.

Real-time monitoring and recording of operating parameters in welding process is convenient for management and regulation.

Matching the circulating cooling water system increases the continuous working capacity of the gun part;

Color 10-inch touch screen, graphic and step-by-step interface design, simple and fast operation.

It has the function of prompting various old chapters, which is safe and reliable.

The manual control device is fully functional, and the 15Kg wire feeding tray can be operated quickly.