In the modern industrial manufacturing and maintenance sectors, welding technology has always been an indispensable process. With technological advancements and evolving market demands, traditional welding techniques have struggled to meet the requirements for efficient and high-quality production. MWELDING, a leader in welding equipment, has brought new changes and breakthroughs to industrial welding with its advanced hot-wire surfacing technology.

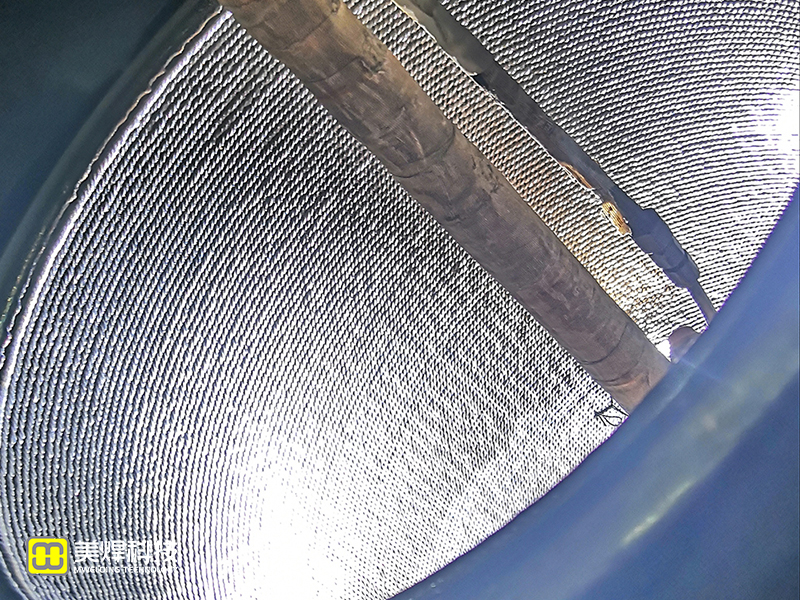

Hot-wire surfacing is a high-quality, efficient, and energy-saving welding process developed based on traditional TIG welding. It utilizes a heat source to melt and bond the base material and welding material, thereby altering or repairing the surface characteristics of the workpiece. MWELDING's hot-wire surfacing technology not only inherits the high-quality weld seams of traditional TIG welding but also demonstrates significant advantages in deposition rates and welding speeds. This technology is widely applied across various industries, including offshore oil, petroleum, petrochemicals, power, nuclear power, automobiles, and more, particularly in pipeline, flange, valve end surfacing, inner wall surfacing, and curved surface surfacing, showcasing impressive welding aesthetics and efficiency.

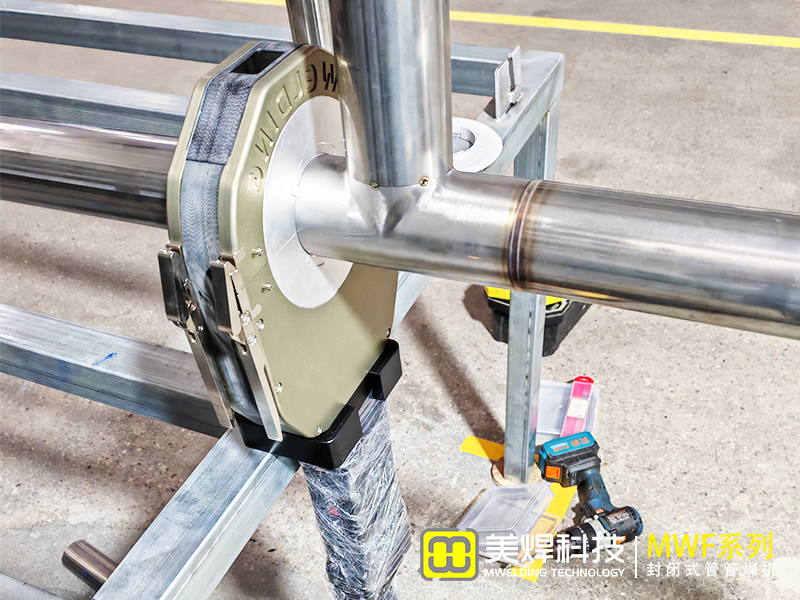

MWELDING's MWLD series of hot-wire surfacing system equipment are the company's star products. These devices feature strong anti-interference capabilities, high reliability, stable speed control, ease of operation, high automation, and specialized welding process management functions such as speed control, current control, wire feeding control, rotation control, quality control, gas protection time control, and arc length automatic control. These functions enable MWELDING's hot-wire surfacing equipment to precisely control welding parameters during the welding process, thereby ensuring dual enhancements in welding quality and production efficiency.

Furthermore, MWELDING's hot-wire surfacing equipment adopts a quick-disassembly modular design, making installation, maintenance, and repairs more convenient. The equipment is also equipped with a circulating water cooling system and a comprehensive gas protection system, ensuring excellent protection of the molten pool throughout the welding process and further improving welding quality and equipment stability.

MWELDING's focus on hot-wire surfacing technology research and application always centers on customer orientation, offering customized services and an integrated service approach without outsourcing. They not only provide standardized hot-wire surfacing system equipment but also support one-on-one customization services to meet the individual needs of different customers. Additionally, MWELDING provides full-cycle welding technical support before, during, and after sales, ensuring customers receive timely and professional assistance throughout the process.

It is worth mentioning that MWELDING's hot-wire surfacing technology has demonstrated exceptional performance in multiple fields. For instance, in the petroleum and petrochemical industries, hot-wire surfacing technology can be used to repair and reinforce various critical components such as pipelines, flanges, and valves, ensuring safe equipment operation. In the power industry, it can be applied to the repair and reinforcement of generator rotors, transformer oil tanks, and other components, improving equipment reliability and service life. Furthermore, in sectors such as shipping, automobiles, aerospace, and aviation, MWELDING's hot-wire surfacing technology has also been widely adopted and recognized.

In summary, MWELDING's hot-wire surfacing technology, with its advantages of efficiency, high quality, and high automation, has become a crucial force in the field of modern industrial welding. With continuous technological advancements and evolving market demands, MWELDING will continue to dedicate itself to the research and innovation of hot-wire surfacing technology, bringing more surprises and breakthroughs to the field of industrial welding. In the future, we have reason to believe that MWELDING's hot-wire surfacing technology will demonstrate its unique charm and value in more fields, contributing significantly to the development of industrial manufacturing and maintenance sectors.